Method and system for analyzing influence of joints on shaft voltage of power generator

A shaft voltage and generator technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of magnetic circuit reluctance asymmetry, accurate analysis of influence, uneven lamination joints, etc., to achieve The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

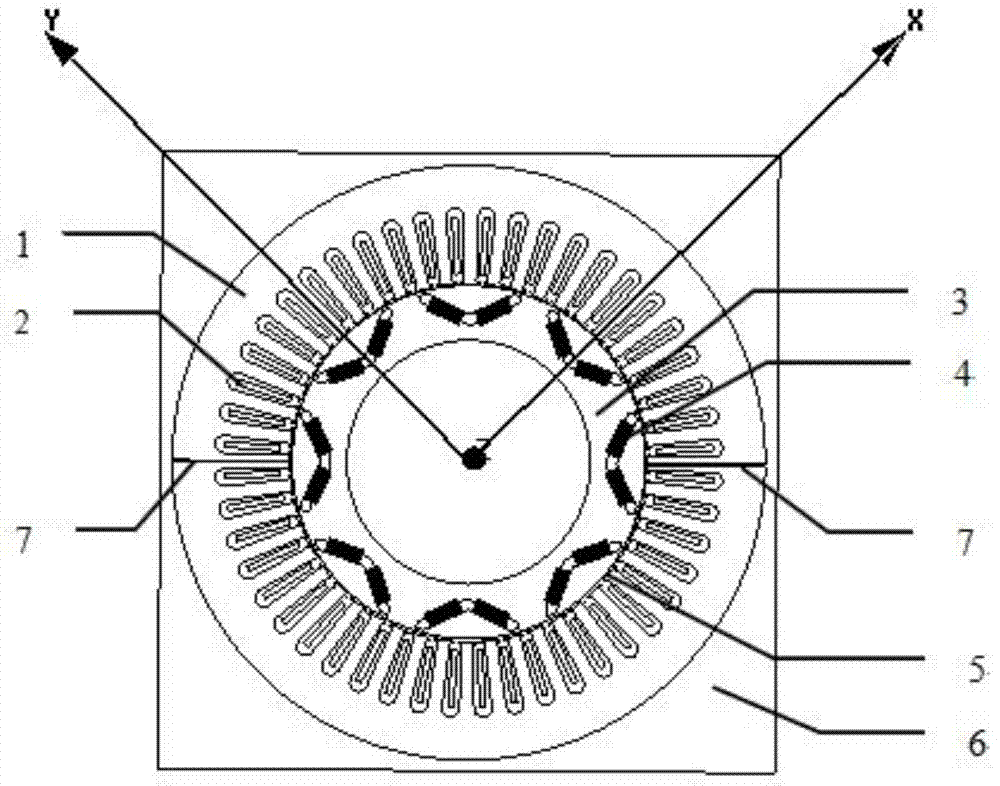

[0019] The method for analyzing the influence of joints on generator shaft voltage in the present invention mainly includes the following steps:

[0020] S1. Establish a generator model in which stator core laminations are not split. The generator model includes a rotor model and a stator model. The stator model is composed of a stator core and stator windings. The rotor model is composed of a rotor core and rotor poles.

[0021] S2, setting the material properties of the above-mentioned parts.

[0022] S3. Establish a surface coordinate system for each rotor magnetic pole; select any focusing point on the rotor magnetic pole plane as the origin of the surface coordinate system, and determine the direction of the X axis after capturing a vertex.

[0023] S4. Divide the stator core of the generator model into two halves on average and move a predetermined distance relative to each other, perform a Boolean operation on the joint on one side to expand the gap to a second predeter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com