Combined heat dissipation device and method for end face and side face of round rod-shaped laser crystal

A technology of laser crystals and cooling devices, which is applied to lasers, laser components, phonon exciters, etc., can solve problems affecting the quality of output beams, uneven heating of crystals, thermal lens effects, etc., to improve conduction and heat dissipation efficiency, improve Uniformity, the effect of improving the contact thermal conductivity value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

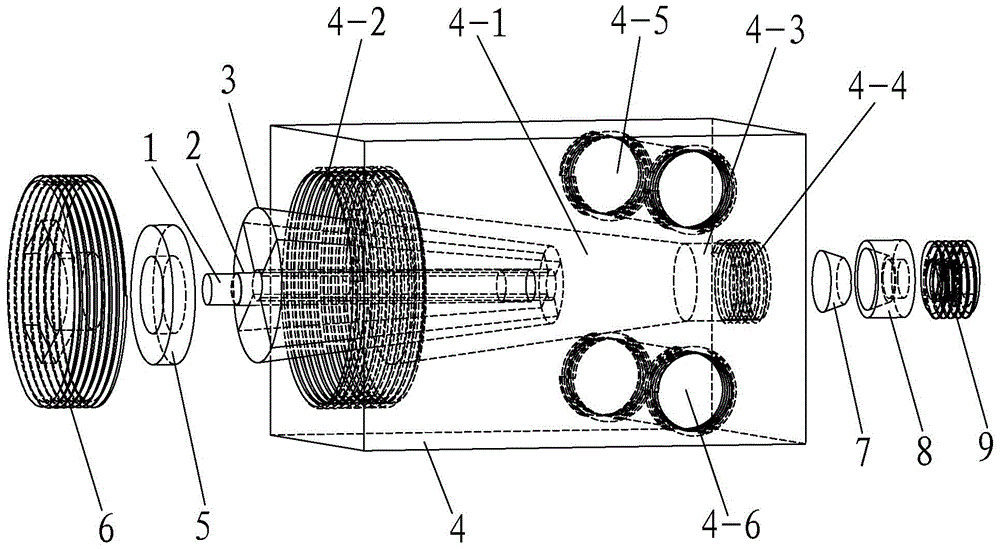

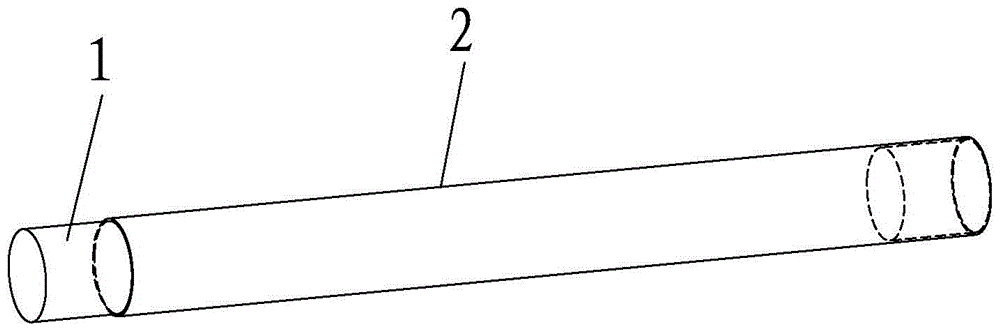

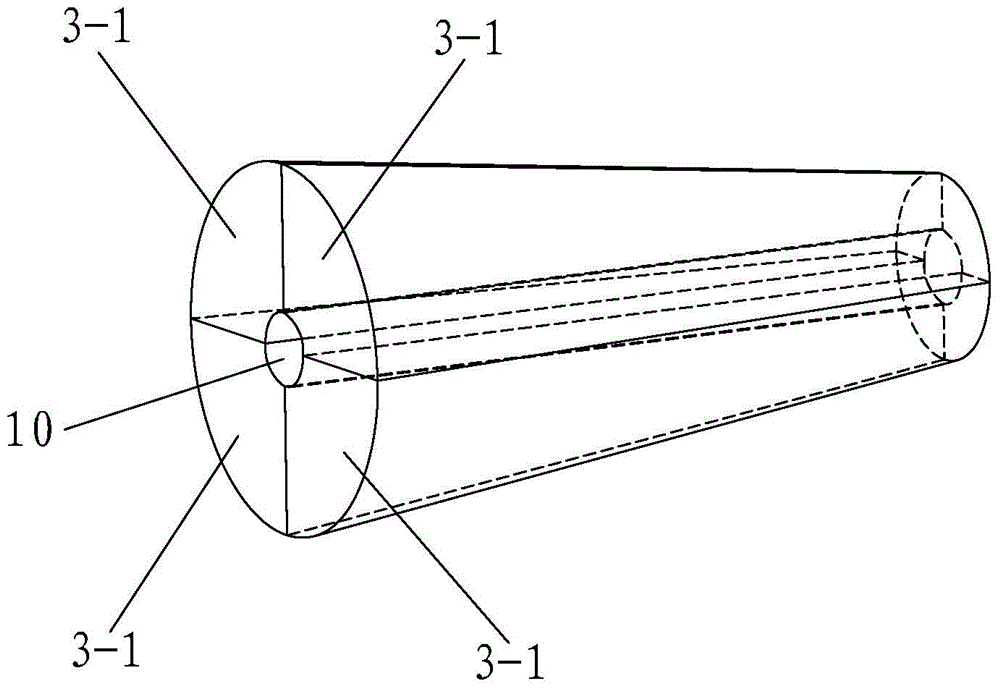

[0048] Such as Figure 1~Figure 10 As shown, the round rod-shaped laser crystal end surface and side surface combined heat dissipation device of the present invention includes a heat sink block 4, a side tight heat dissipation component and an end surface tight heat dissipation component, and the side tight heat dissipation component includes a thermal interface material 2 for clamping and wrapping. The crystal clamping assembly 3 of the round rod-shaped laser crystal 1 and the side tightening bolt 6 for forcefully tightening the crystal clamping assembly 3, a metal is arranged between the crystal clamping assembly 3 and the side tightening bolt 6 Spacer 5; the crystal clamping assembly 3 is composed of four clamping blocks 3-1 with the same structure, the shape of the outer contour of the clamping block 3-1 is a quarter truncated cone shape, the clamping Block 3-1 is provided with a quarter-arc-shaped groove 3-2 at the position where the two planes intersect. After the four cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com