Sizing agent for carbon fibers, carbon fiber strand, and fiber-reinforced composite material

一种碳纤维、浆剂的技术,应用在碳纤维、纤维处理、薄料处理等方向,能够解决基体树脂浸渗、粘度高、无法表现出复合材料机械特性等问题,达到优异粘接性、优异物性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

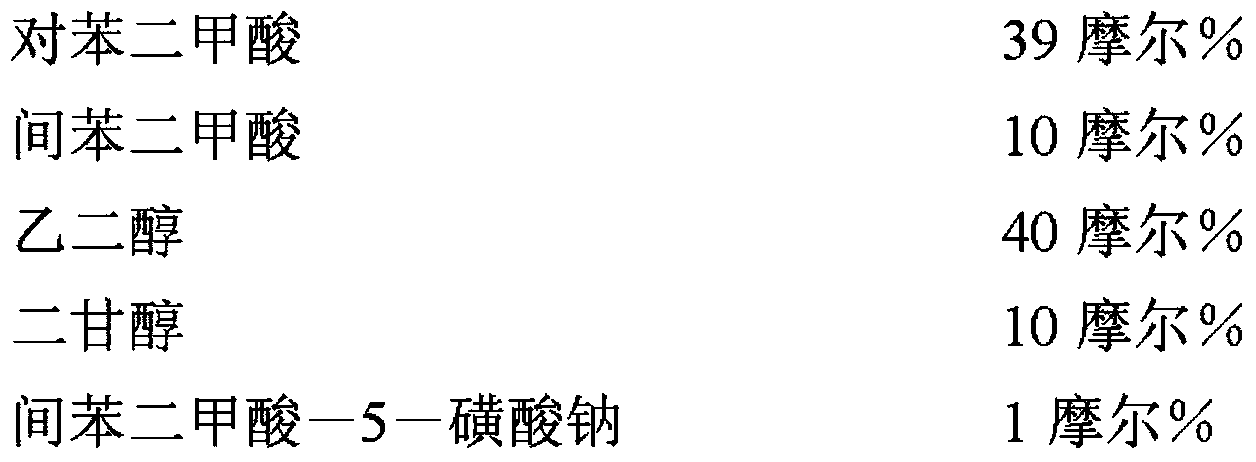

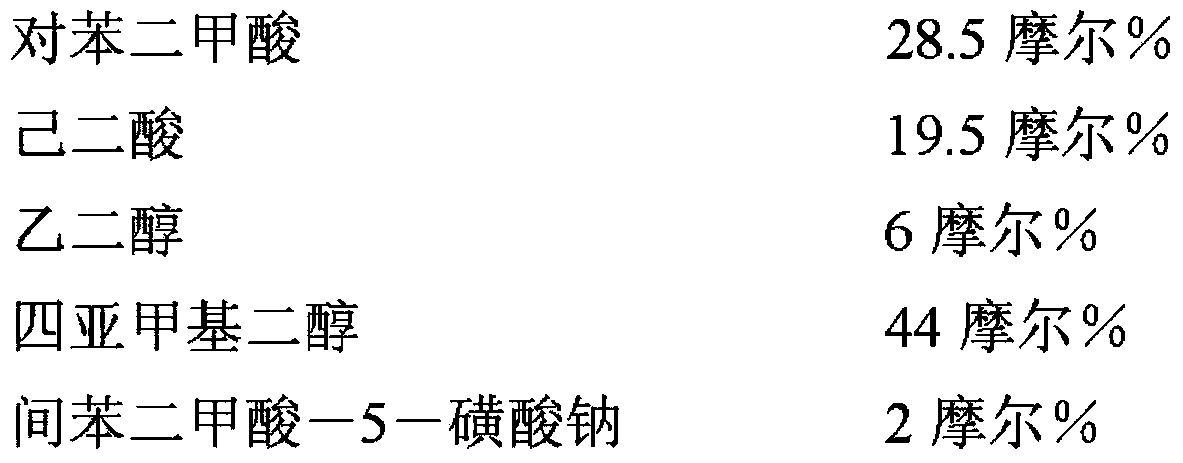

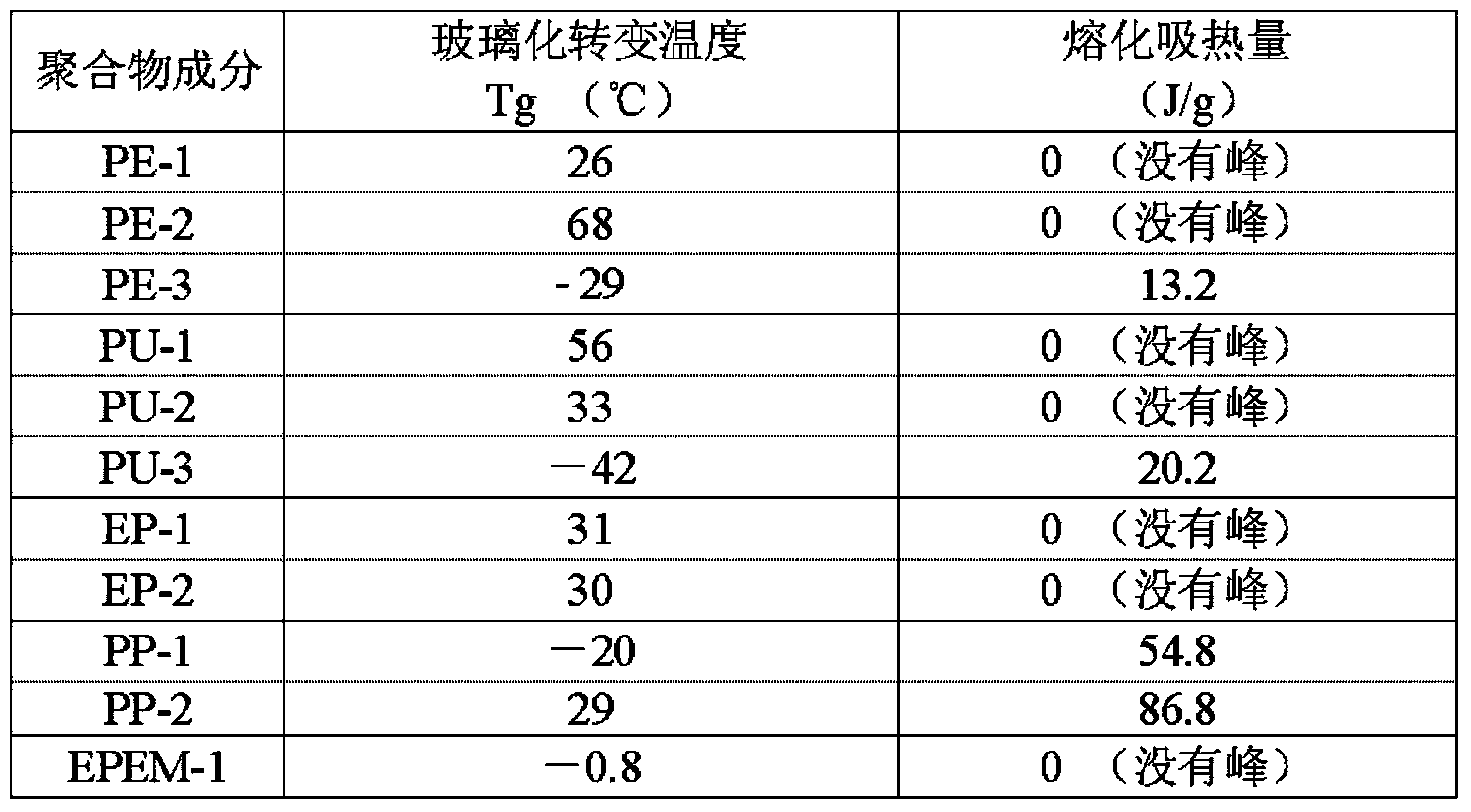

[0110] Hereinafter, although an Example demonstrates this invention concretely, it is not limited to the Example described here. In addition, the percentage (%) shown in the following examples means "% by weight" unless otherwise specified. The measurement of each characteristic value was performed based on the method shown below.

[0111]

[0112] According to JIS-K7121, it measures with a differential scanning calorimeter (DSC) (JADE DSC LAB SYSTEM manufactured by Perkinelmer Instruments) under conditions of a sample weight of about 10 mg and a heating rate of 10° C. / min. Specifically, a sample accurately weighed at 10±1 mg was set in a differential scanning calorimeter, and the temperature was raised to the melting temperature Tm+30° C. of the sample confirmed by the pre-measurement. Then, the temperature was lowered to the glass transition temperature Tg-50°C confirmed by the prediction, and then the temperature was raised to 300°C at a heating rate of 10°C / min. In the...

manufacture example 10

[0153] In the autoclave equipped with stirring device, add maleic anhydride modified polyethylene resin (ethylene / maleic anhydride graft copolymerization ratio (weight%): 97.5 / 2.5, weight average molecular weight: 10000) 200 parts, oleyl alcohol polyoxygen 93 parts of ethylene (15) ether and 8 parts of potassium hydroxide were heated up to 170-180° C. under nitrogen reflux and stirring. Then, 699 parts of water were slowly poured in with stirring, and stirred at 170 to 180° C. for 2 hours to dissolve the contents uniformly. Thereafter, it was cooled to normal temperature, and water content was adjusted to obtain modified polyolefin resin PP-2 as an aqueous emulsion having a nonvolatile content of 30% by weight.

[0154] [Manufacturing example 11]

[0155] In the emulsifier, add bisphenol A type epoxy resin (Japan Epoxy Resin company system " JER (registered trademark) 1001 " 153 parts, liquid bisphenol A type epoxy resin (Japan Epoxy Resin company system " JER (registered tra...

Embodiment 1

[0160] The above-mentioned aromatic polyester resin PE-1 of Manufacturing Example 1 was diluted with water to prepare a sizing agent emulsion with a non-volatile component concentration of 15 wt%. , filament count 12000), after hot air drying at 105°C for 15 minutes, to obtain a sizing agent-treated carbon fiber tow with a theoretical adhesion of 5%. The wettability and adhesiveness of the matrix resin were evaluated for this tow by the method described above. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com