Automatic capsule falling and pushing-out linkage mechanism

A linkage mechanism and automatic technology, which is applied in capsule delivery, drug delivery, and pharmaceutical formulations, can solve problems such as low work efficiency, troublesome operation, and poor hygienic environment, and achieve high work efficiency, fast and convenient operation, and a high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

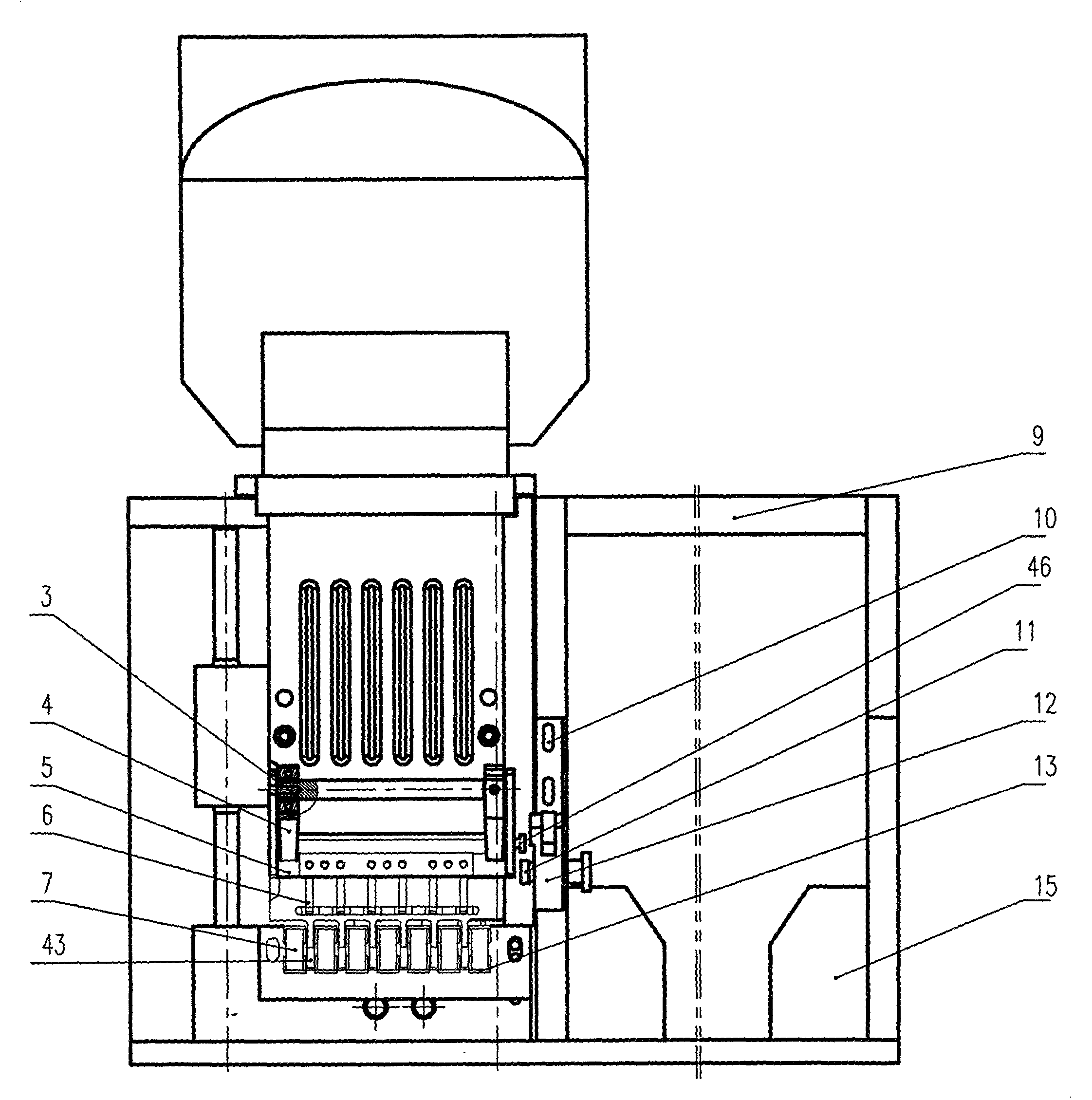

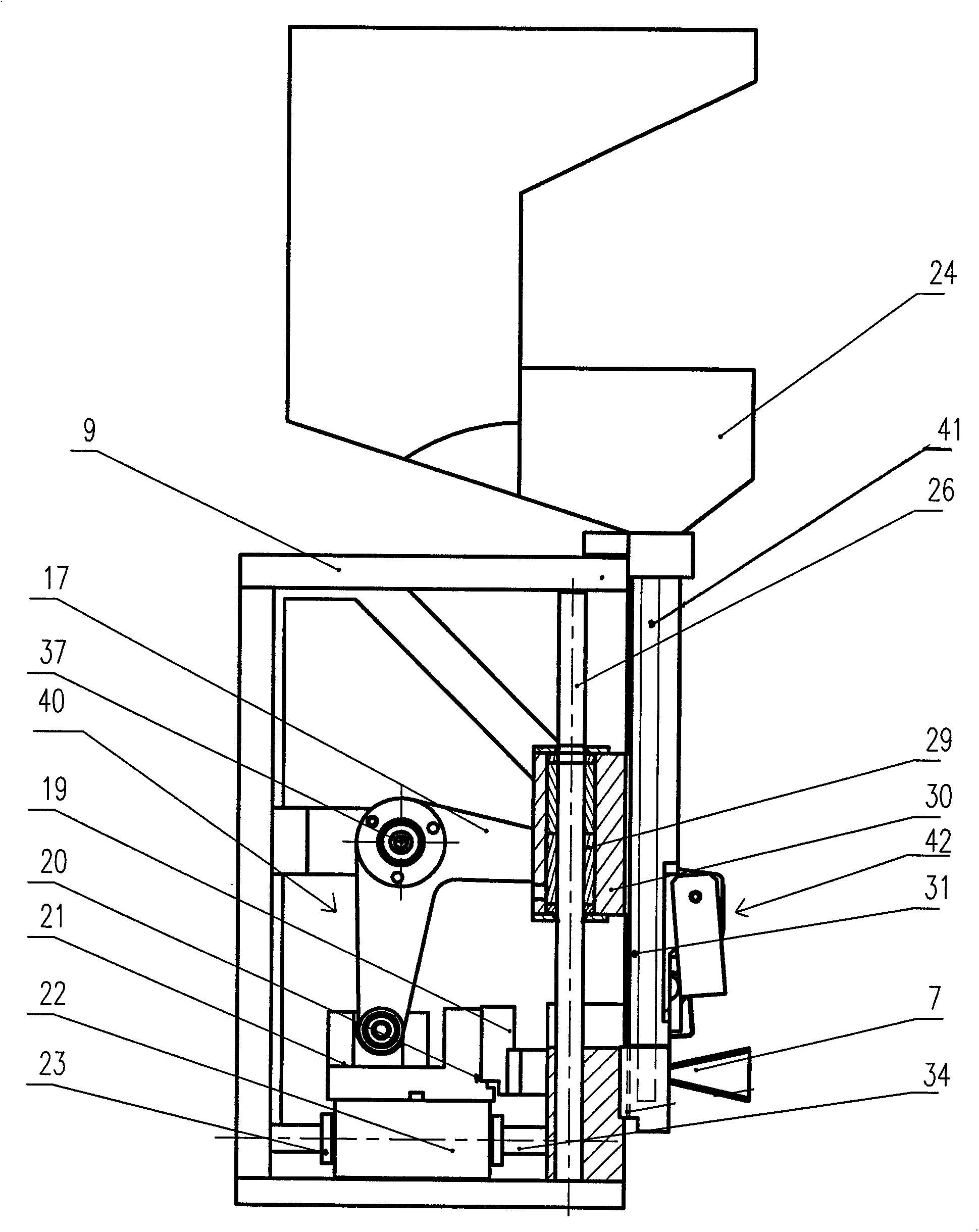

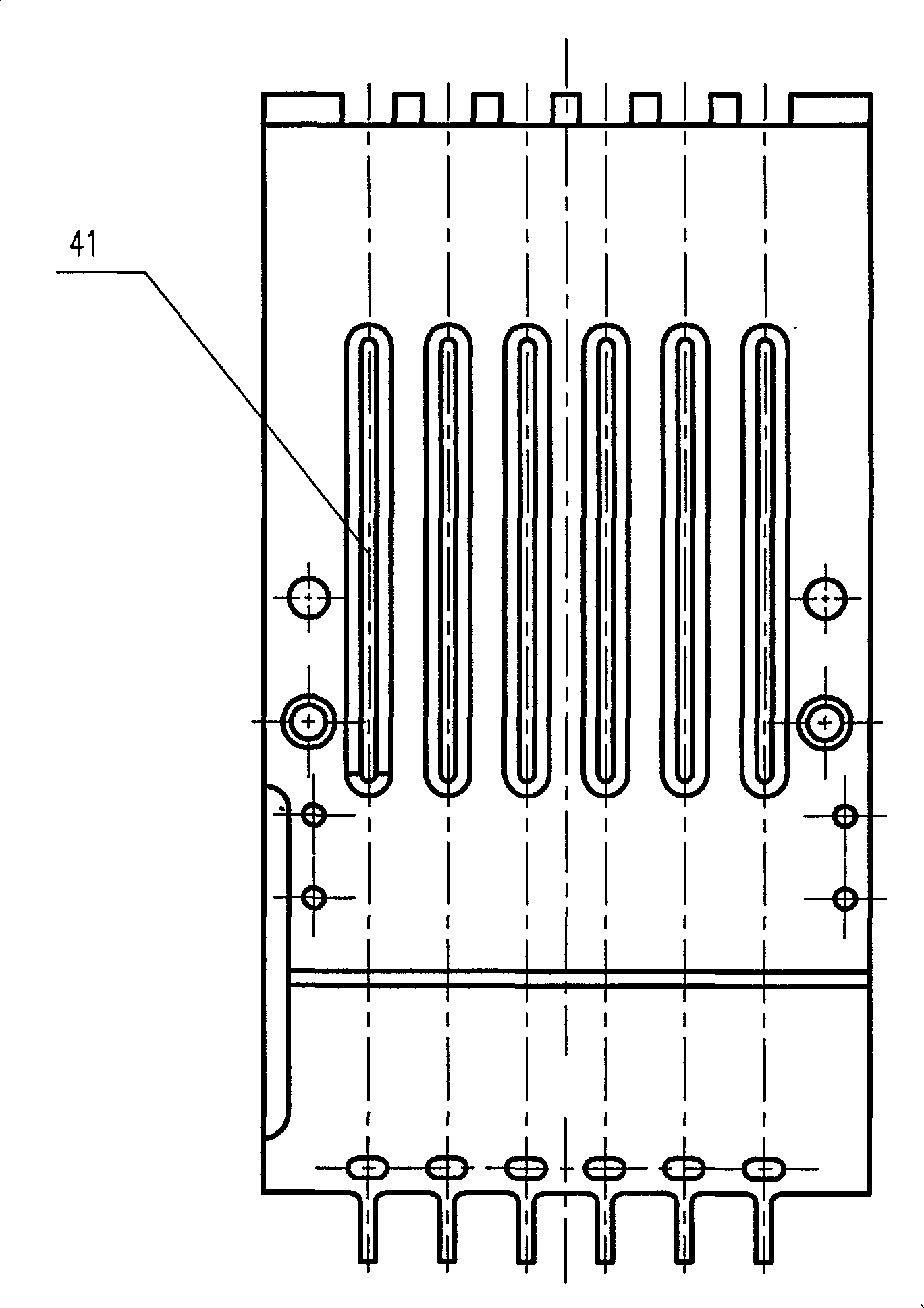

[0010] refer to Figure 1 to Figure 3 , the automatic capsule drop and push-out linkage mechanism of the present invention applied to the hard capsule powder returning machine includes a frame 9 on which (longitudinally arranged) feeding and discharging punches 31 (with several longitudinal passages) are housed. , for the capsule to fall freely), the material stopper assembly 42 is housed on the described feeding and discharging punch 31, and the described stopper assembly 42 includes the material stopping spring 6 (the number of which is the same as the longitudinal channel of the sending and discharging punch) Corresponding), the material retaining spring 6 can be inserted horizontally (blocking the capsule so that it does not fall temporarily) or pulled out against the longitudinal channel of the feeding and discharging punch 31. The material retaining spring 6 passes through the material retaining bracket 5 and the retaining material The material support shaft 3 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com