Anesthesia machine and method for allowing anesthesia machine to operate normally when airway pressure sensor of anesthesia machine fails

A technology of airway pressure and normal work, applied in the direction of respirators, etc., can solve problems such as undetectable, patient injury, machine not working normally, etc., and achieve the effect of ensuring normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

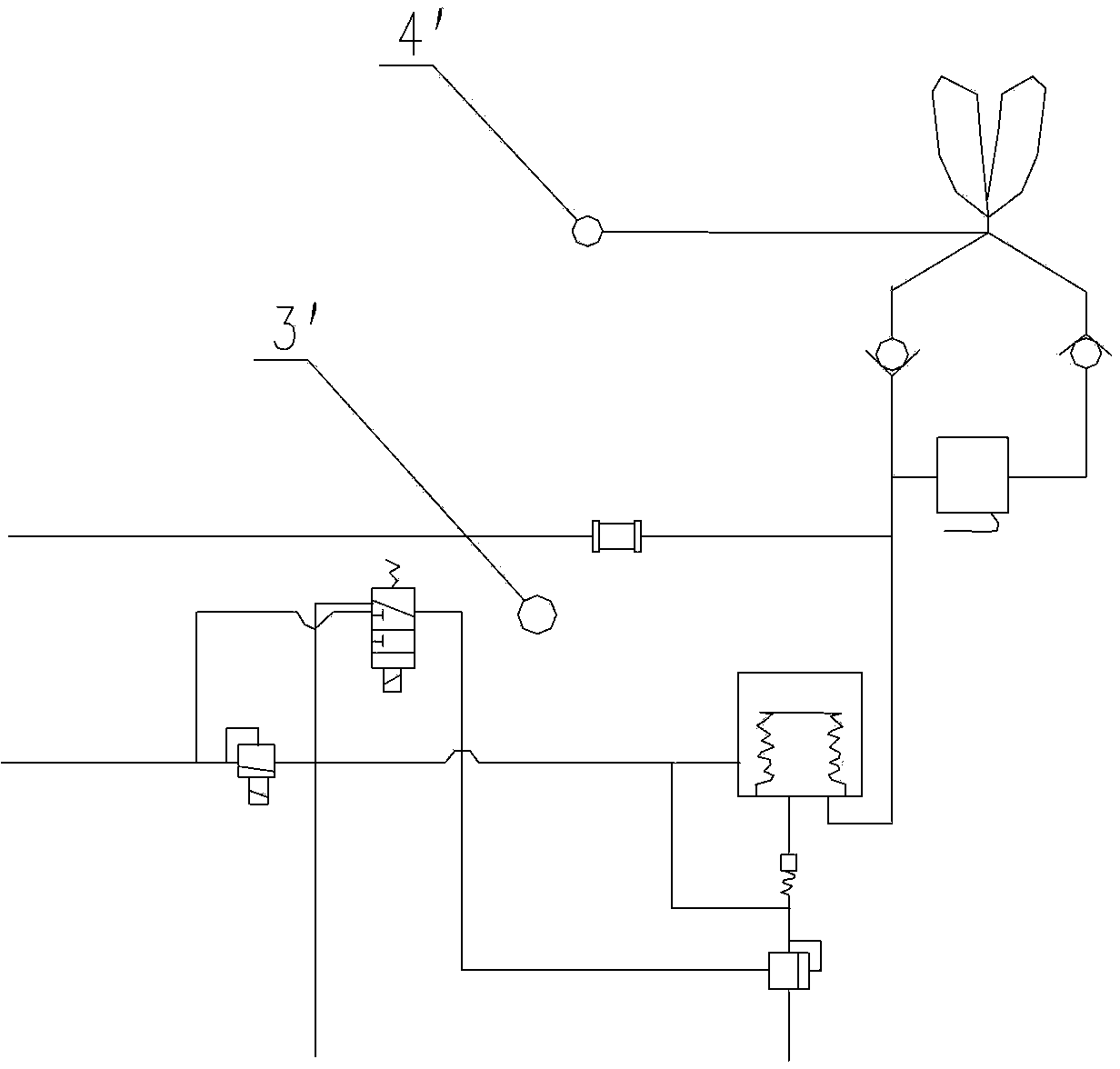

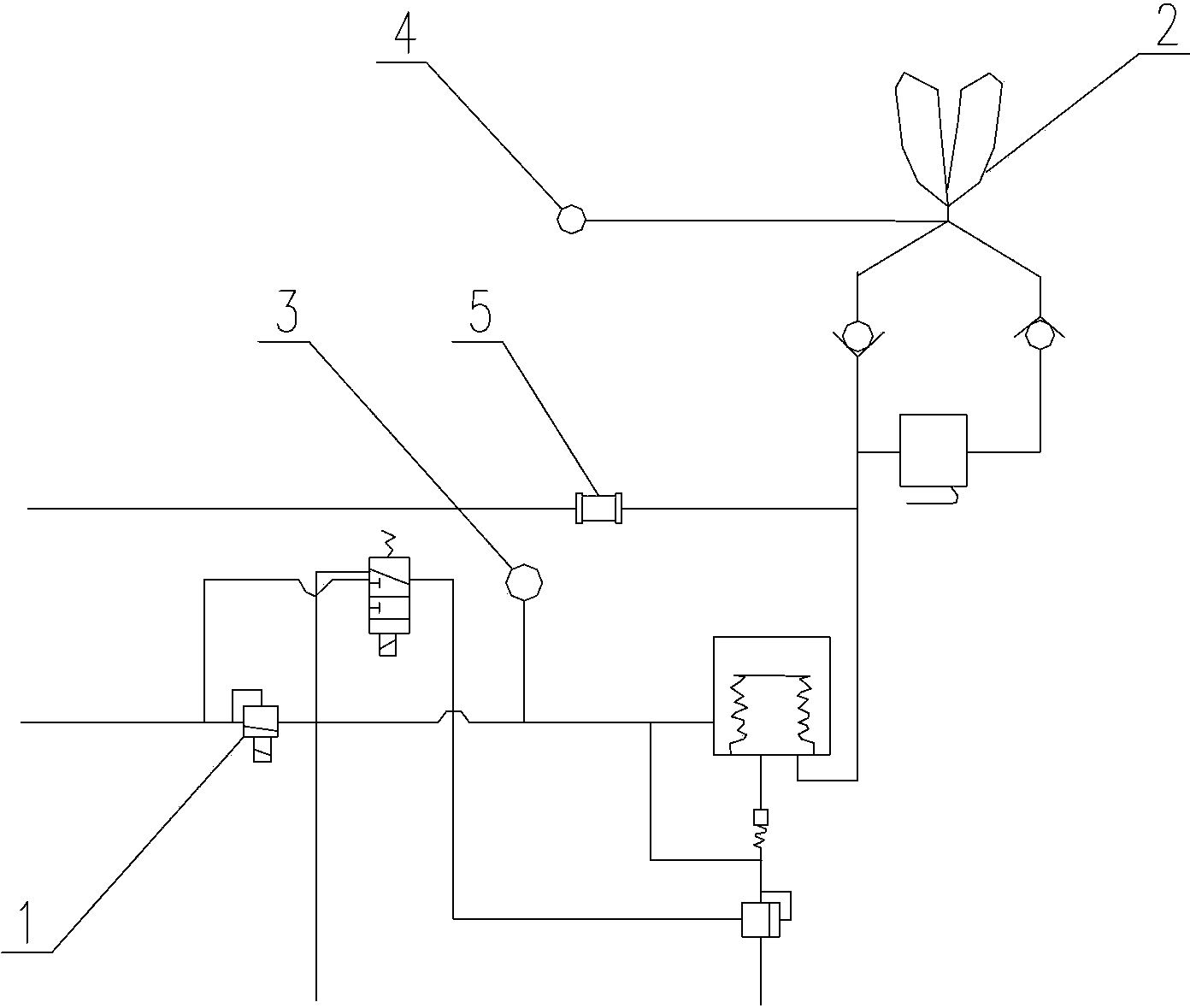

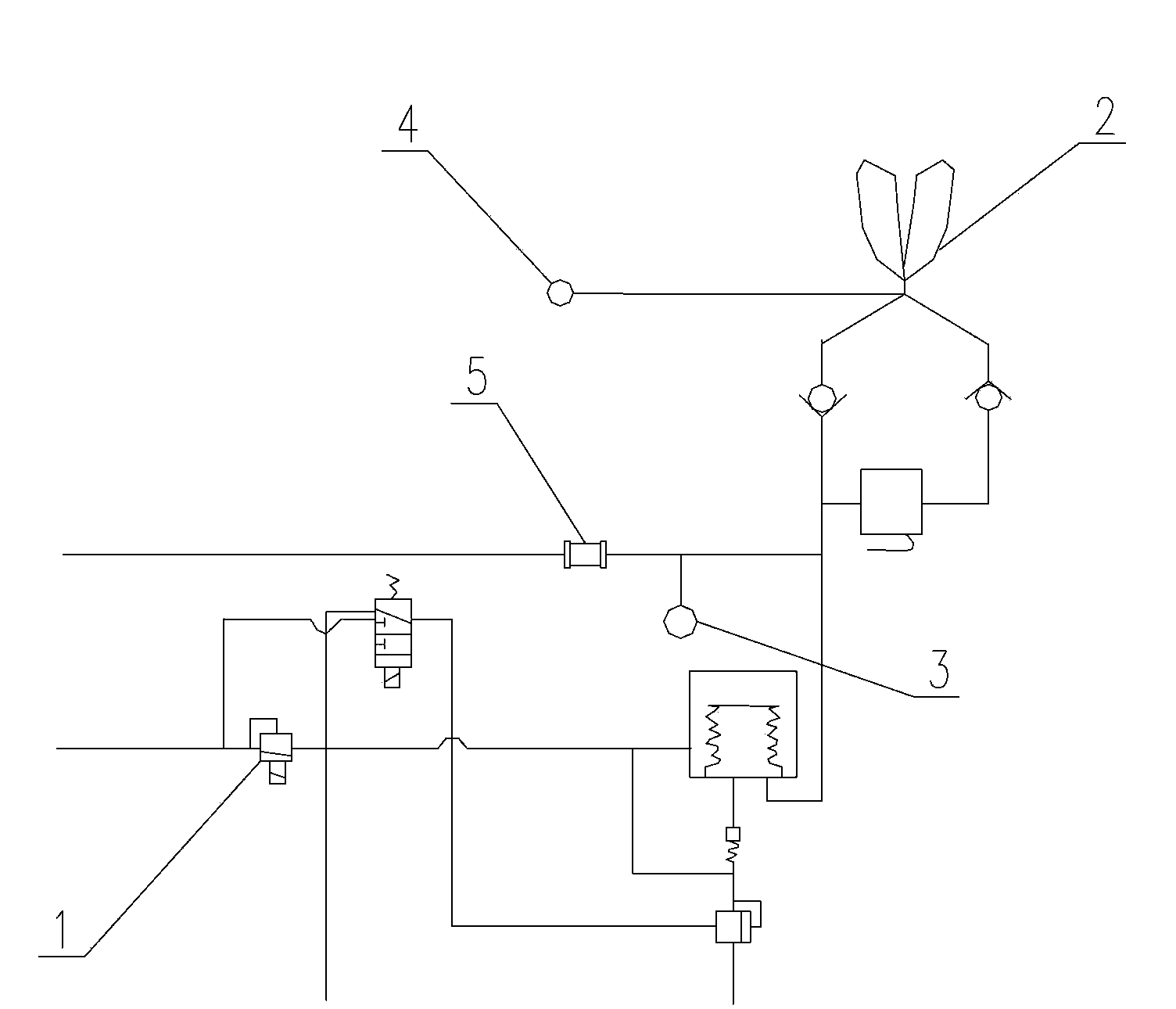

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0034] Such as Figures 2 to 4 As shown, the present invention provides an anesthesia machine, which has the function of ensuring that the anesthesia machine can still work normally under the action of the environmental pressure sensor when the airway pressure sensor of the anesthesia machine fails, wherein the anesthesia machine specifically includes a breathing circuit, The circuit includes an inspiratory branch, one end of which is connected to the driving gas through an inspiratory valve 1, and the other end is connected to the patient's inspiratory end 2; an exhalation branch, one end of which is connected to the patient's The exhalation end 2 is connected, and the other end is connected to the atmosphere through the PEEP valve, wherein the exhalation circuit also includes an ambient pressure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com