Portable foam extinguisher capable of automatically foaming

A foam fire extinguishing agent and fire extinguisher technology, which is applied in fire rescue and other directions, can solve the problem of not mentioning the specific structure of the fire extinguishing foam device, and achieve the effects of improving utilization efficiency and fire extinguishing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

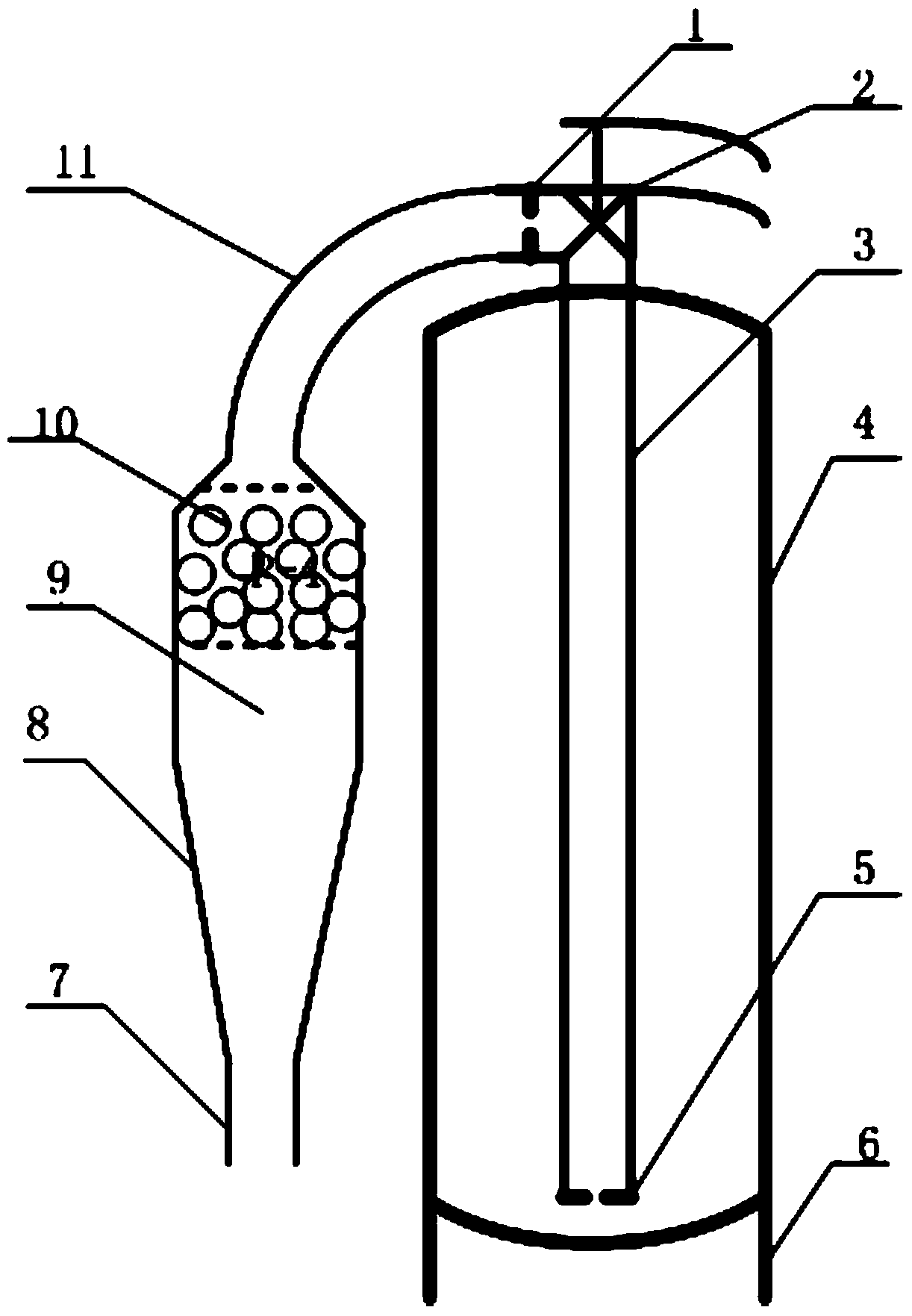

[0051] In the fire extinguisher cylinder with a volume of 8L, fill 6L of foam fire extinguishing agent in which 143g of carbon dioxide has been dissolved, and pressurize it to 1.2MPa~1.4MPa with air or nitrogen.

[0052] The diameter of the flow control orifice is 4.0 mm, which is placed at the outlet of the valve head; 50 mm of glass beads with a diameter of 4 mm are added to the rear of the foam gun, and the inner diameter of the foam outlet is 14 mm. The foam injection time is 71s, the expansion ratio is 7.5, the foam is concentrated between 4.5m and 8.0m, the farthest spray distance is 8.7m, and there is no foam within 4.2m.

[0053] According to the requirements of item 7.3 of GB14351.1-2005 "Portable Fire Extinguishers Part 1: Performance and Structure Requirements", the fire extinguishing experiment of Class B fire was carried out. There is re-ignition, and there is still gasoline left in the pan.

specific Embodiment 2

[0054] Fill the fire extinguisher cylinder with a volume of 12L into 9L of foam fire extinguishing agent, fill in carbon dioxide while shaking, and dissolve 189g of carbon dioxide in total, pressurize to 1.2MPa~1.4MPa with air or nitrogen.

[0055] The flow control orifice has a diameter of 4.5 mm and is placed at the bottom of the straw; 50 mm of glass beads with a diameter of 4 mm are added to the rear of the foam gun, and the inner diameter of the foam outlet is 15.5 mm. The foam injection time is 88s, the expansion ratio is 8.0, the foam is concentrated between 3.5m and 5.5m, the farthest spray distance is 8.0m, and there is no foam within 2.8m.

[0056] According to the requirements of item 7.3 of GB14351.1-2005 "Portable Fire Extinguishers Part 1: Performance and Structure Requirements", the fire extinguishing experiment of Class B fire was carried out. There is re-ignition, and there is still gasoline left in the pan.

specific Embodiment 3

[0057] In the fire extinguisher cylinder with a volume of 12L, fill 9L of foam fire extinguishing agent in which 199g of carbon dioxide has been dissolved, and pressurize it to 1.2MPa~1.4MPa with air or nitrogen.

[0058] The diameter of the flow control orifice is 5.1 mm, which is placed at the outlet of the valve head; 65 mm of plastic beads with a diameter of 5 mm are added to the front of the foam gun, and the inner diameter of the foam outlet is 17 mm. The foam injection time is 59s, the expansion ratio is 8.0, the foam is concentrated between 4.0m and 7.0m, the farthest spray distance is 7.5m, and there is no foam within 2m to 2.5m.

[0059] According to the requirements of item 7.3 of GB14351.1-2005 "Portable Fire Extinguishers Part 1: Performance and Structure Requirements", the fire extinguishing experiment of Class B fire was carried out. There is re-ignition, and there is still gasoline left in the pan.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com