Device for online observation and removal of dust on the surface of transmission mirror and its implementation method

An implementation method, dust technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using gas flow, etc. Avoid secondary pollution, high observation accuracy and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

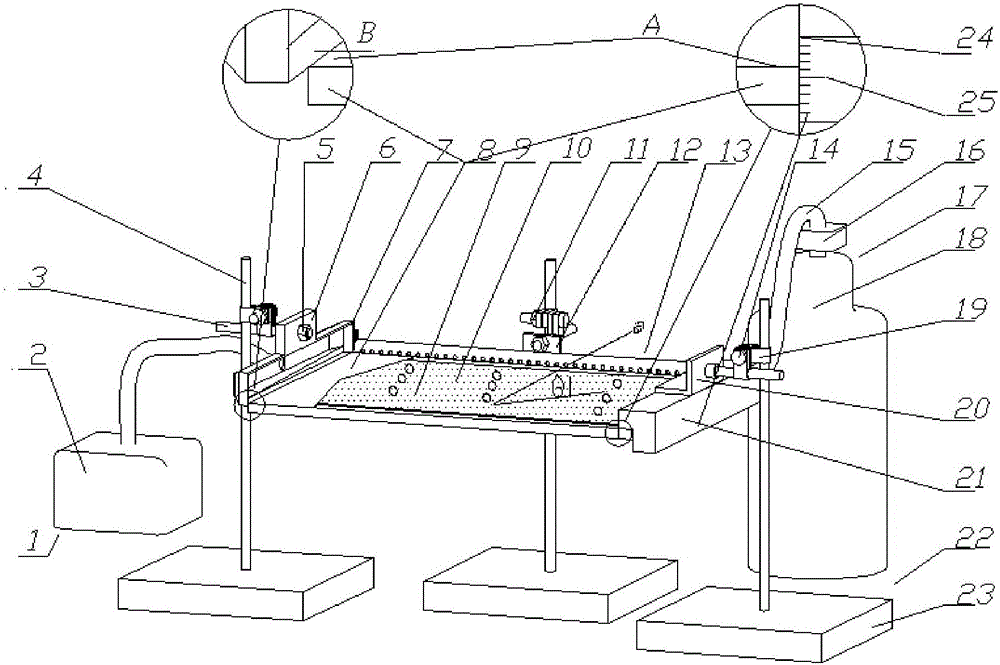

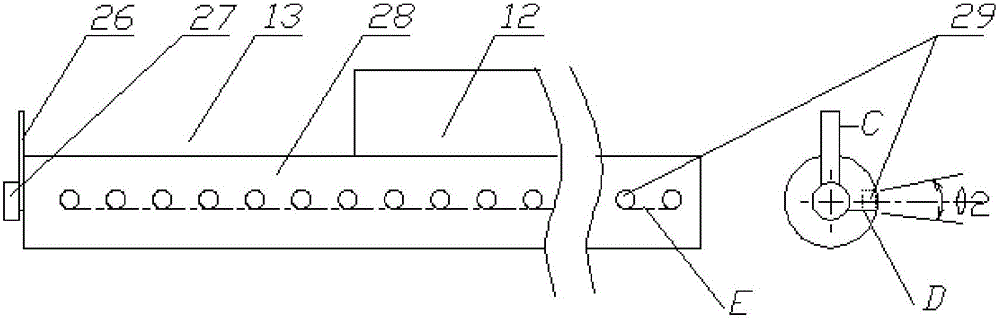

[0028] The present invention will be further described in conjunction with accompanying drawing and embodiment now.

[0029] see figure 1 , figure 2 , as can be seen from the figure, the transmission mirror surface dust online observation and removal device in the high-power laser device of the present invention includes a purging system 17, an illumination system 13, a dust collection system 1 and three sets of identical support positioning systems 22:

[0030] The support positioning system 22 includes a base 23, a support rod 4, a fixed connecting rod 3), a nut a5, a nut b11, a bolt 14 and two clamps 19, and the support rod 4 is vertically connected to the base 23 by threads; Two identical clamps 19 are connected by bolts 14 and nuts b11 and can rotate axially around the bolts 14; one clamp 19 is fixed on the support rod 4 with adjustable height and can rotate around the axial direction of the support rod 4; 19 Fix the fixed connecting rod 3, the connecting rod 3 can rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com