Rotary cutting tool with stable structure

A technology of rotating cutting tools and stable structure, applied in the field of metal cutting tools, can solve the problems of reducing the precision and cutting efficiency of the machined surface, reducing the cutting speed and precision of the cutting tool, unstable structure of the cutting tool groove, etc., so as to improve the machined surface. Accuracy and cutting efficiency, the effect of increasing cutting speed and precision, reducing contact strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

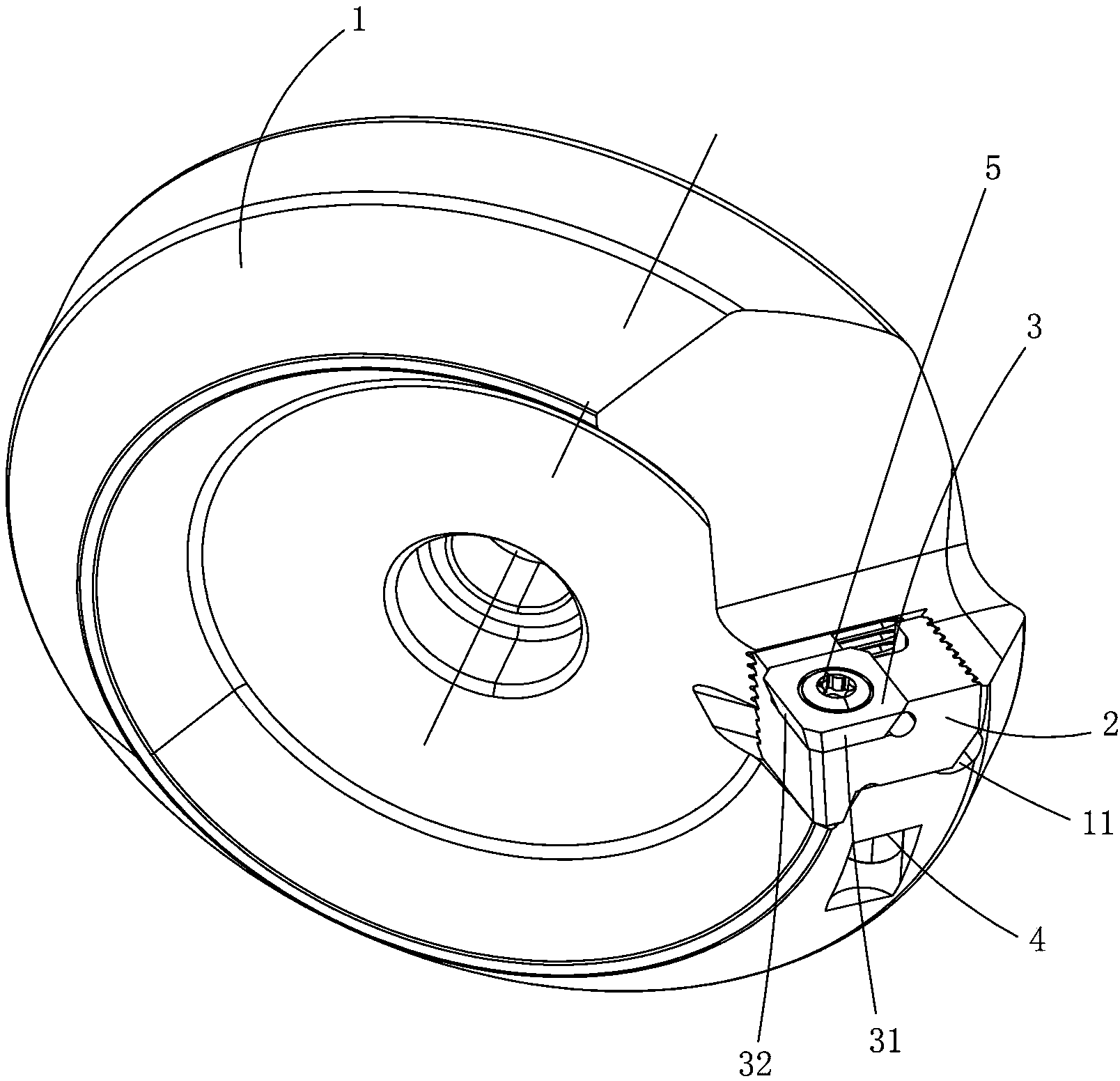

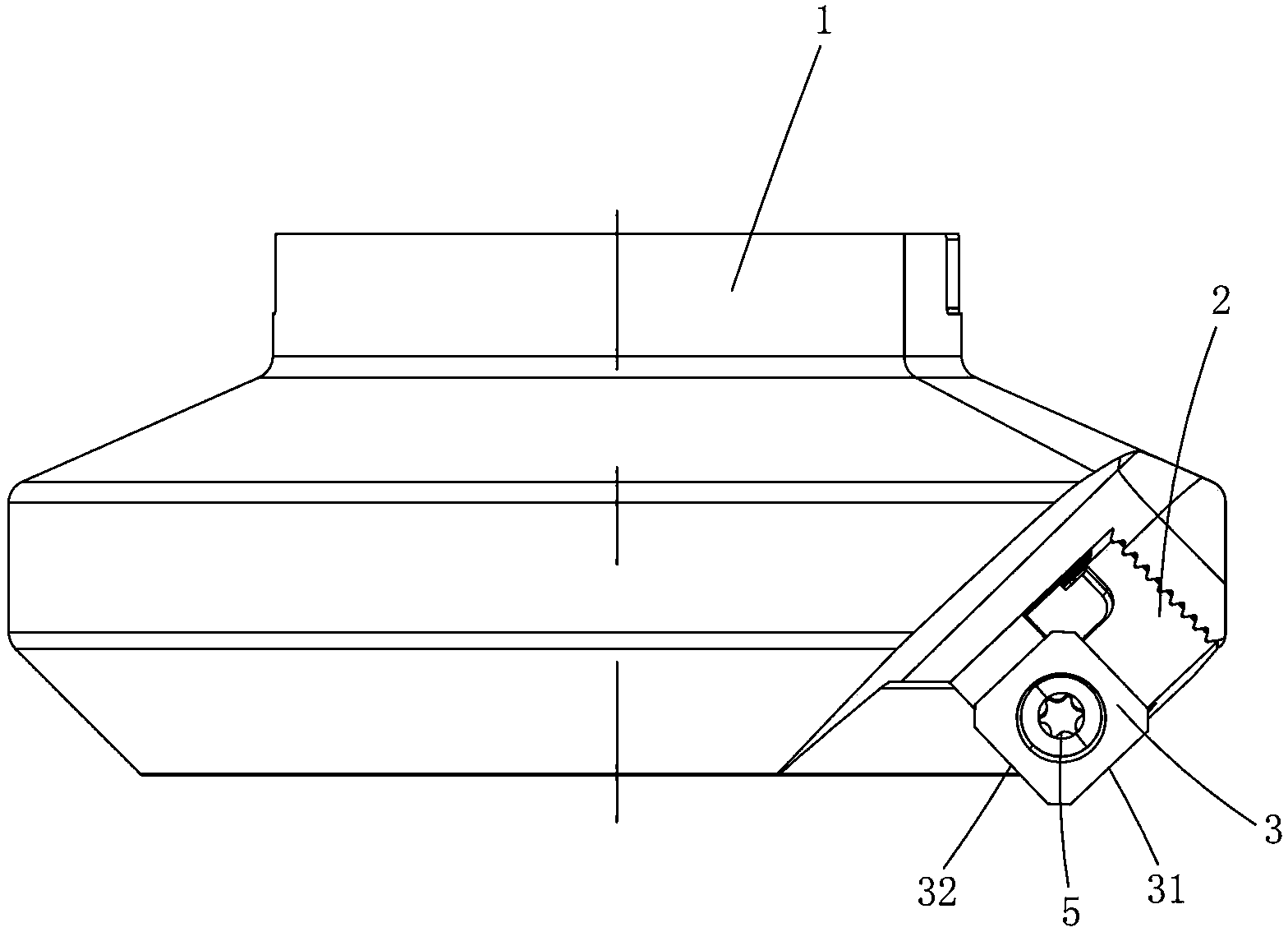

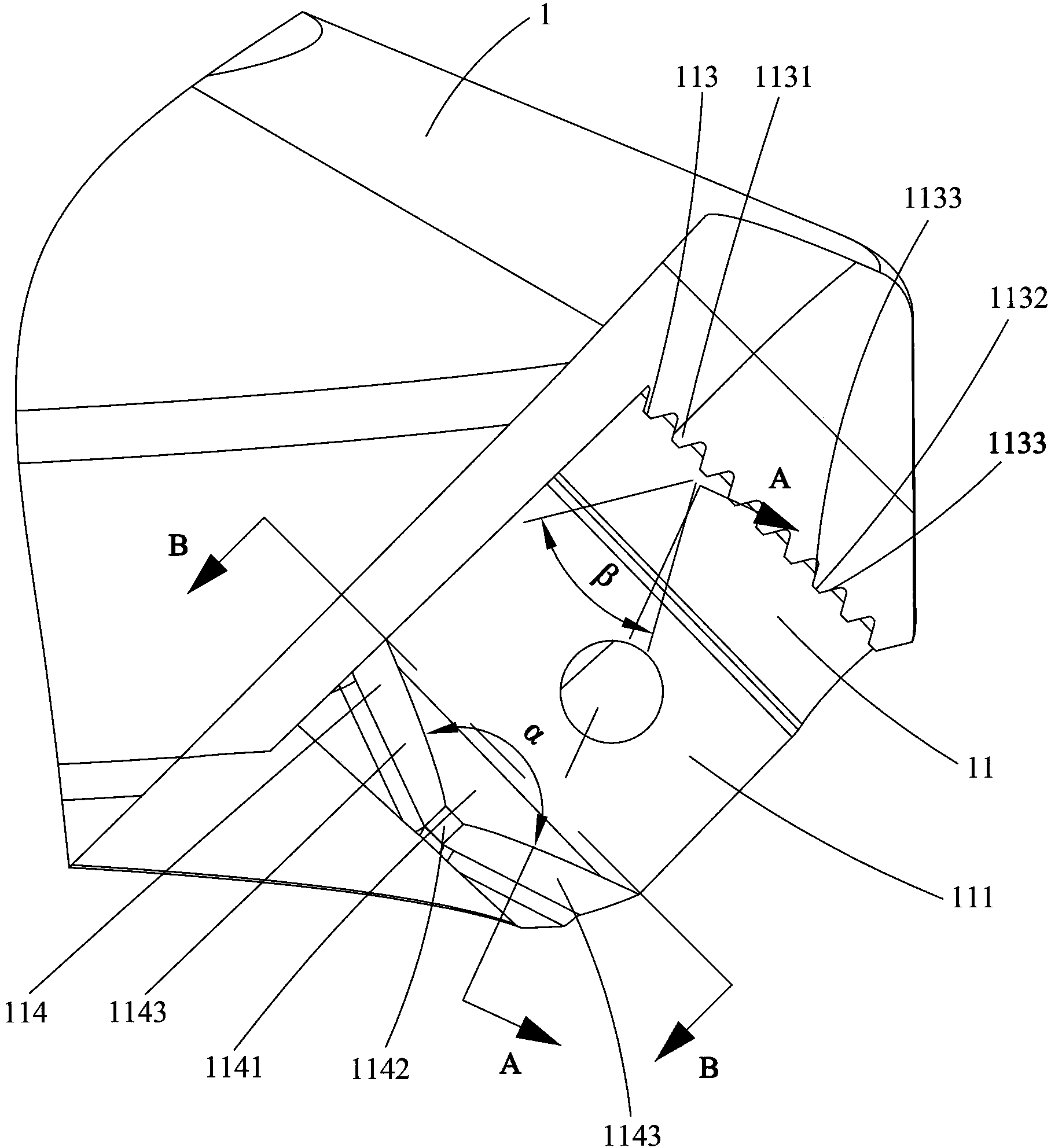

[0032] Figure 1 to Figure 9 A structurally stable rotary cutting tool embodiment of the present invention is shown, the rotary cutting tool includes a rotary cutter body 1, a tool holder 2, a cutting blade 3, a tool holder fastener 4 and a blade fastener 5, the rotary cutter body 1 is provided with a sipe 11 surrounded by a bottom positioning surface 111, a side positioning surface 112 and an end positioning surface 113. The cutting blade 3 is fixed on the tool holder 2 through a blade fastener 5. The side cutting edge 31 is opposite, the end positioning surface 113 is opposite to the end cutting edge 32 of the cutting blade 3, and the end of the sipe 11 near the end cutting edge 32 is provided with a front end positioning surface 114 intersecting with the bottom positioning surface 111, and the front end positioning surface 114 is provided with a first protrusion 1141, and the bottom of the tool holder 2 is provided with a first recess 21 at the end near the end cutting edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com