Method for controlling vacuum degree of automobile brake boosting system

A power assist system and automobile braking technology, applied in the direction of brakes, brake transmissions, vehicle components, etc., can solve problems such as noise interference, high EVP cost, and reduced fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

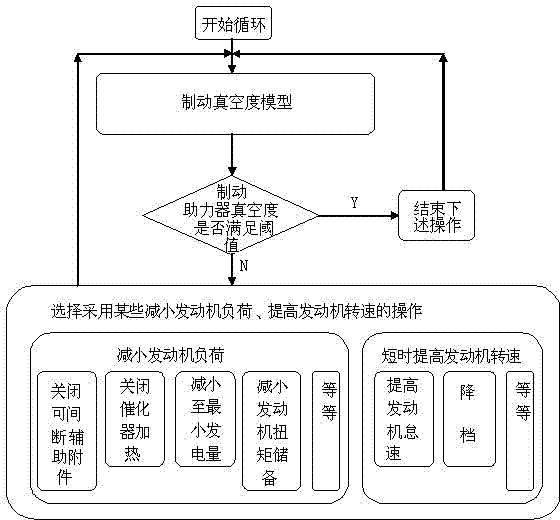

[0028] A method for controlling the vacuum degree of a brake booster system of an automobile, comprising the following steps, first setting a vacuum degree threshold and a delay time according to vehicle design parameters, then establishing a brake vacuum degree model, and using the brake vacuum degree every time a delay time passes The current vacuum degree of the brake booster is judged once based on the vacuum degree model and the vacuum degree threshold value, and the following selection is made according to the judgment result: 1) When the current vacuum degree of the brake booster meets the vacuum degree threshold value, wait for the next comparison; 2. ) When the current vacuum of the brake booster does not meet the vacuum threshold requirement, increase the vacuum of the brake booster by reducing the engine load and / or increasing the engine speed.

[0029] Vacuum degree in this patent = ambient air pressure - measuring point air pressure

[0030] The brake vacuum degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com