Power generation device and method using medium-temperature and medium-pressure steam and low-pressure saturated steam in metallurgical industry

A steam and low-pressure technology, applied in steam engine installations, energy industry, machines/engines, etc., can solve problems such as abandonment, energy loss, etc., and achieve the effect of avoiding pollution and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention provides the following embodiments:

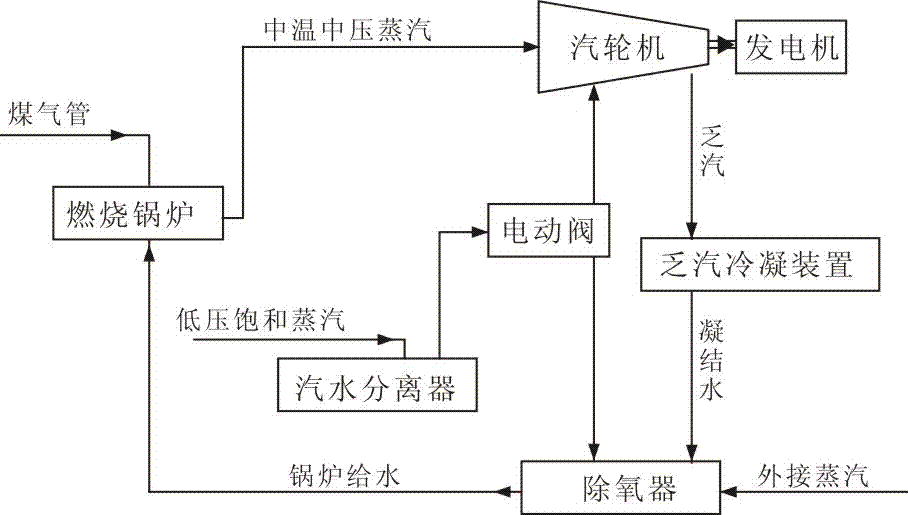

[0036] The steps of the method for generating electricity using medium-temperature, medium-pressure steam and low-pressure saturated steam in the metallurgical industry provided by the present invention are as follows:

[0037] 1. Collect a small amount of gas produced, and heat the collected gas to burn the boiler.

[0038] 2. The combustion boiler produces medium-temperature and medium-pressure steam, which is input to the main steam interface of the steam turbine to drive the steam turbine to rotate, and the steam turbine drives the generator to generate electricity.

[0039] 3. Input the low-pressure saturated steam to the steam-water separator, dry it through the steam-water separator, distribute the dried low-pressure saturated steam to the steam turbine auxiliary steam interface and deaerator through the electric valve, and use it to add auxiliary power to the steam turbine, and at the same time Deaeration of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com