Five-shift car gearbox

A technology for automobile transmissions and transmissions, which is applied to vehicle transmissions, vehicle components, gear transmissions, etc. It can solve the problems of long axial dimensions of transmissions, insufficient power output, and weak climbing ability, so as to shorten the installation distance and improve the bearing capacity. ability, the effect of improving assembly performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

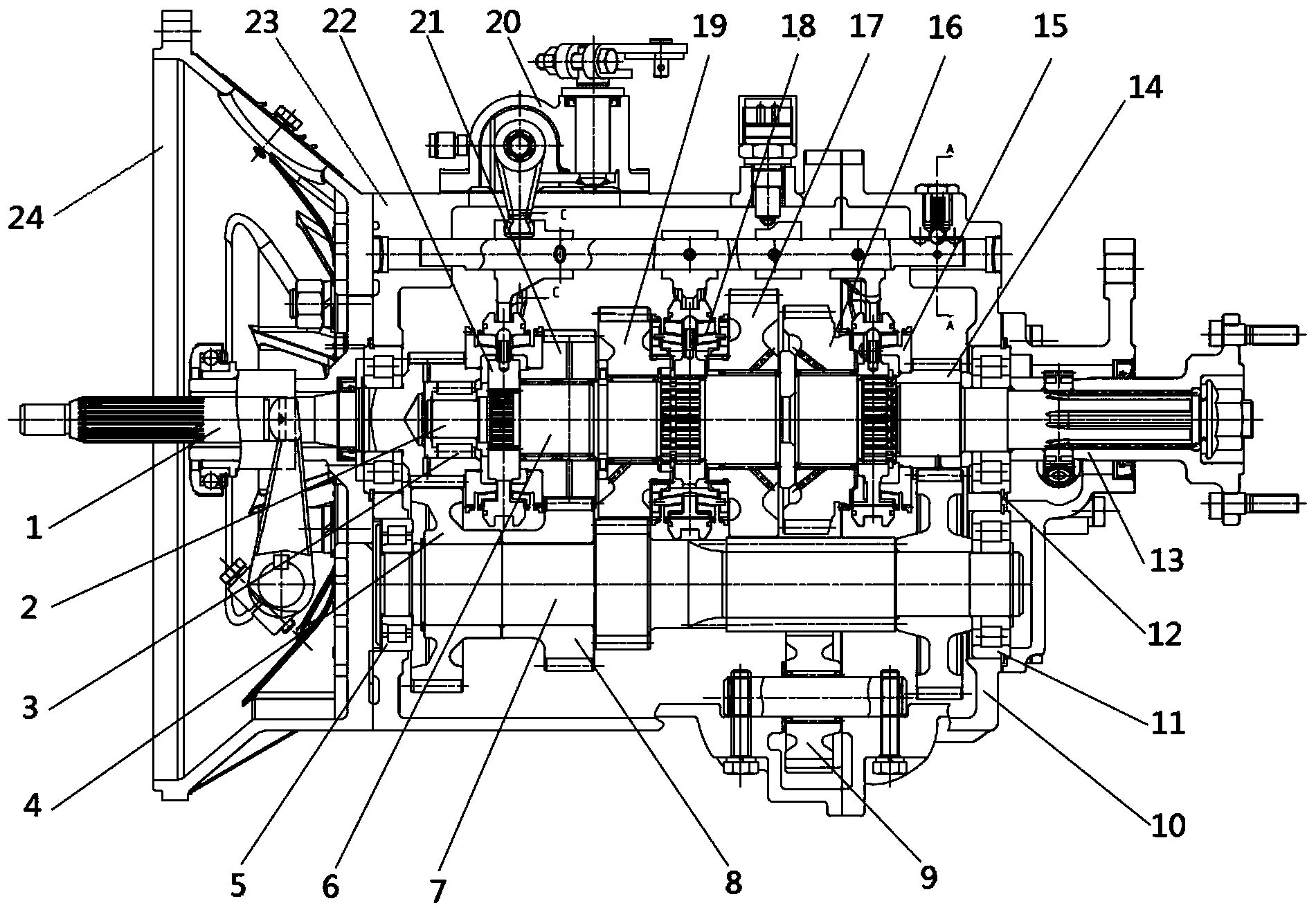

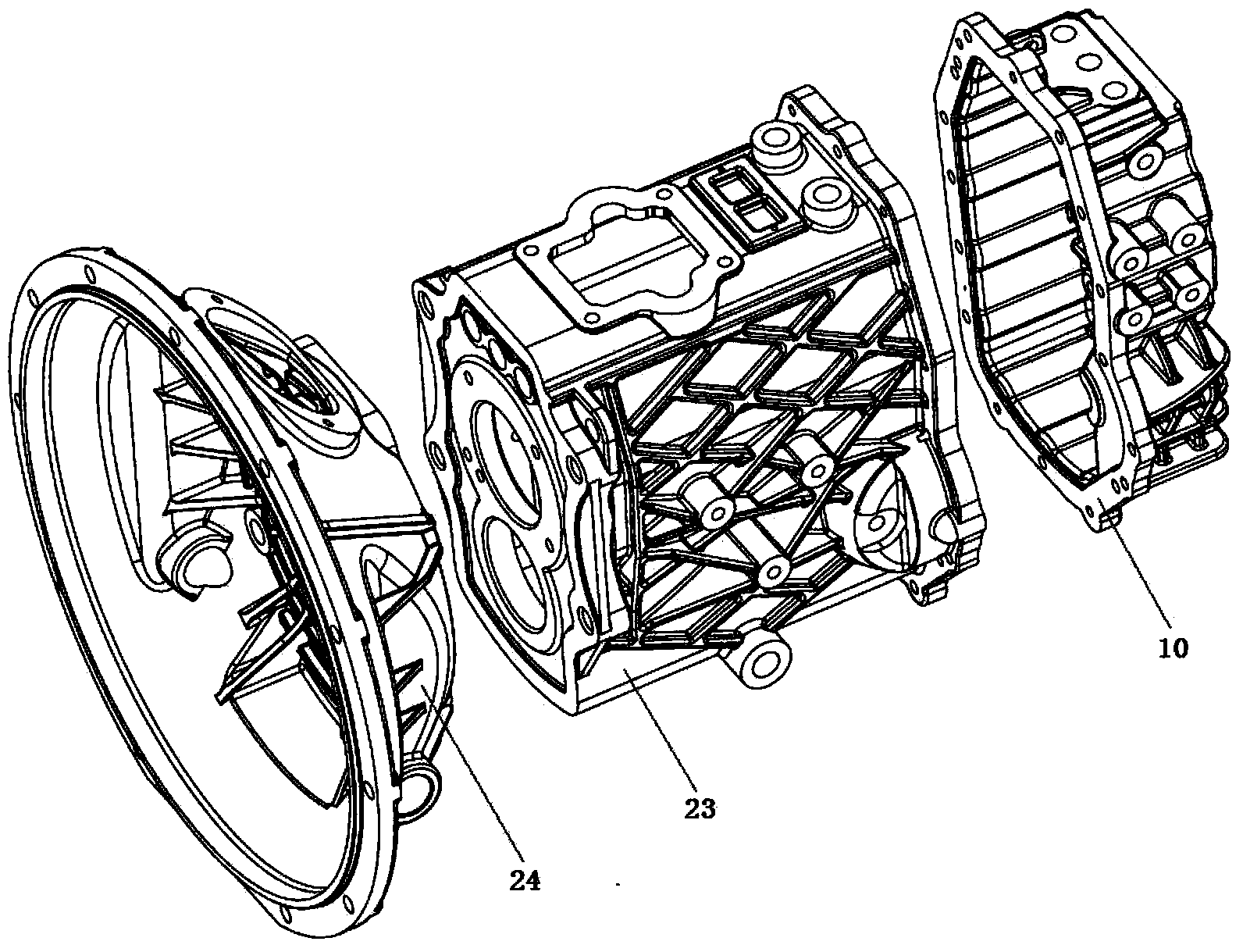

[0026] A kind of five-speed automobile transmission of the present invention, as figure 1 As shown, the overall structure is a single intermediate shaft transmission; the power input end is the front end and the left end, and the power output end is the rear end and the right end; The assembly is supported on the inner ring of a shaft and the rear housing 10 of the transmission through the cylindrical roller bearing 3 without outer ring and the cylindrical roller bearing 12 respectively. Five gears are arranged on the second shaft 6, between the first shaft gear and the second shaft third speed gear 21, the second shaft second speed gear 19 and the second shaft first speed gear 17, there are three or four gear synchronizers with a single taper surface respectively 22 and the first and second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com