A hydraulic torque converter for a low-speed road roller

A technology of hydraulic torque converter and road roller, which is applied in the field of hydraulic torque converter, can solve the problems of high fuel consumption and failure of hydraulic torque converter, and achieve the effect of high fuel consumption and reasonable power matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

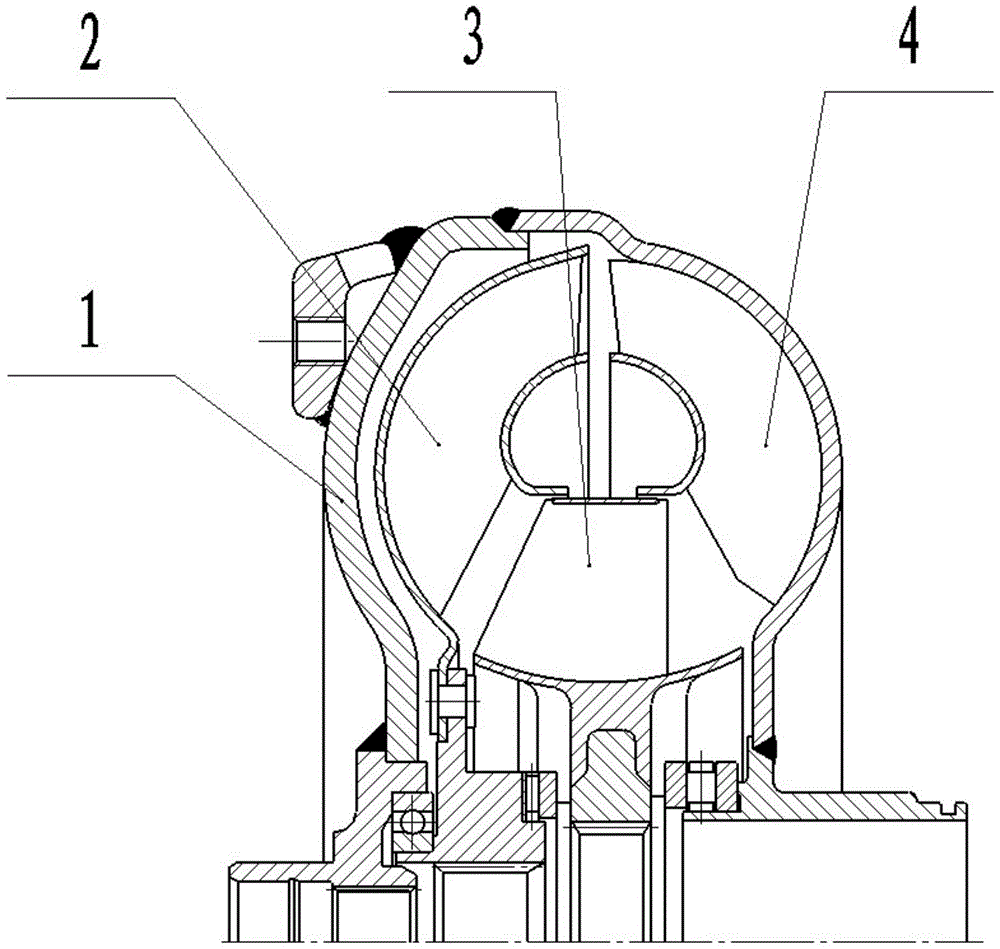

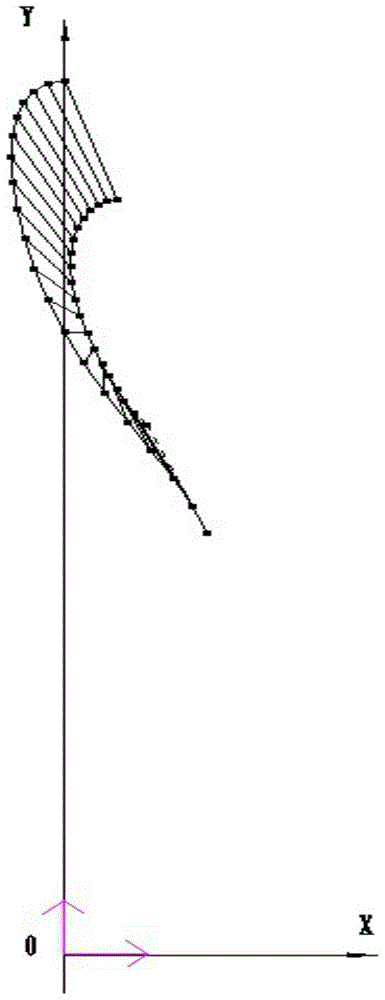

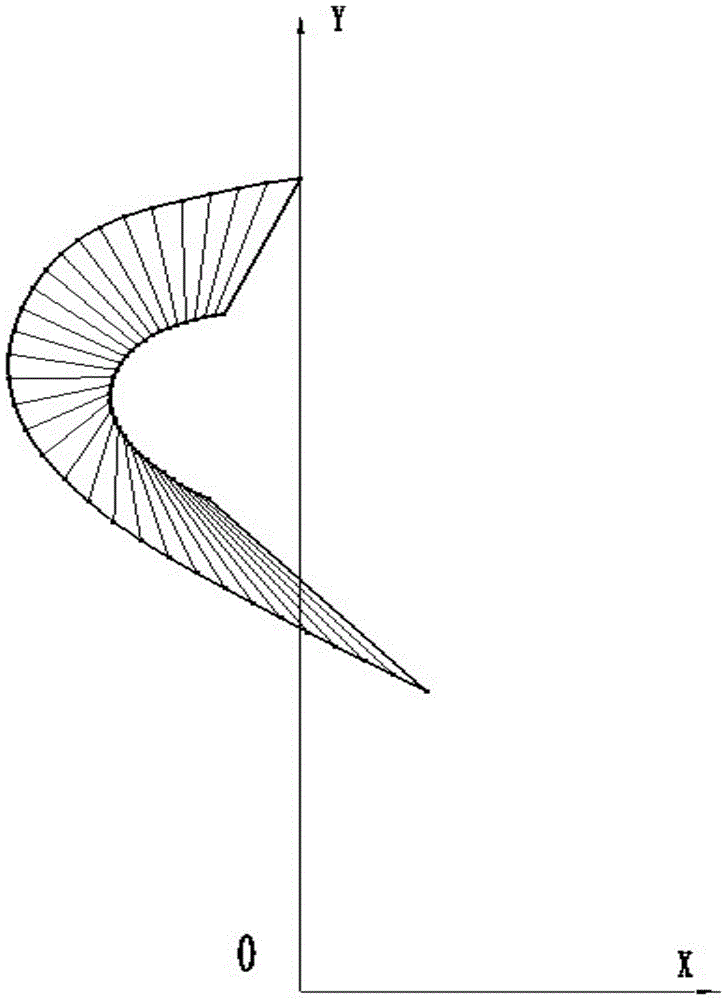

[0061] Such as Figure 1 to Figure 5 As shown, this example is mainly composed of a cover wheel assembly 1, a turbine assembly 2, a guide wheel assembly 3, and a pump wheel assembly 4; wherein: the power input end is composed of the cover wheel 1 and the pump wheel 4, and the power output end is passed by the turbine 2 Turbine shaft composition. The specific structural parameters of each working wheel are as follows:

[0062] The diameter of the circulating circle of the hydraulic torque converter φD is 340±4mm;

[0063] The average inlet and outlet radius of the middle streamline of each working wheel:

[0064] The average inlet radius ρ of the middle streamline of the impeller body B1 =92.7±2mm;

[0065] The average radius ρ of the outlet of the middle streamline of the impeller body B1 =158.5±2mm;

[0066] The average inlet radius ρ of the middle streamline of the turbine body T1 =158.5±2mm;

[0067] The average radius ρ of the outlet of the middle streamline of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com