Blowing-type burner control method

A control method and burner technology, applied in the direction of controlling combustion, lighting and heating equipment, etc., can solve the problems of flame temperature drop, increase in size and power, increase in air supply, etc., to prevent ignition and deflagration, and improve heat exchange efficiency , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for controlling a blast burner. The blast burner controlled by the method includes a combustion box, a blower, an electric controller and an operator. The combustion box is provided with a flame current sensing needle, a gas proportional valve assembly, and an ignition The electric controller is connected to the blower, the operator, the flame current sensing needle, the gas proportional valve assembly, the igniter and the temperature relay, respectively. The gas proportional valve assembly includes an electric shut-off valve and an electric regulating port. The operator is mainly responsible for Issue various instructions for use and stop use, and display the use status and alarm code when a failure occurs.

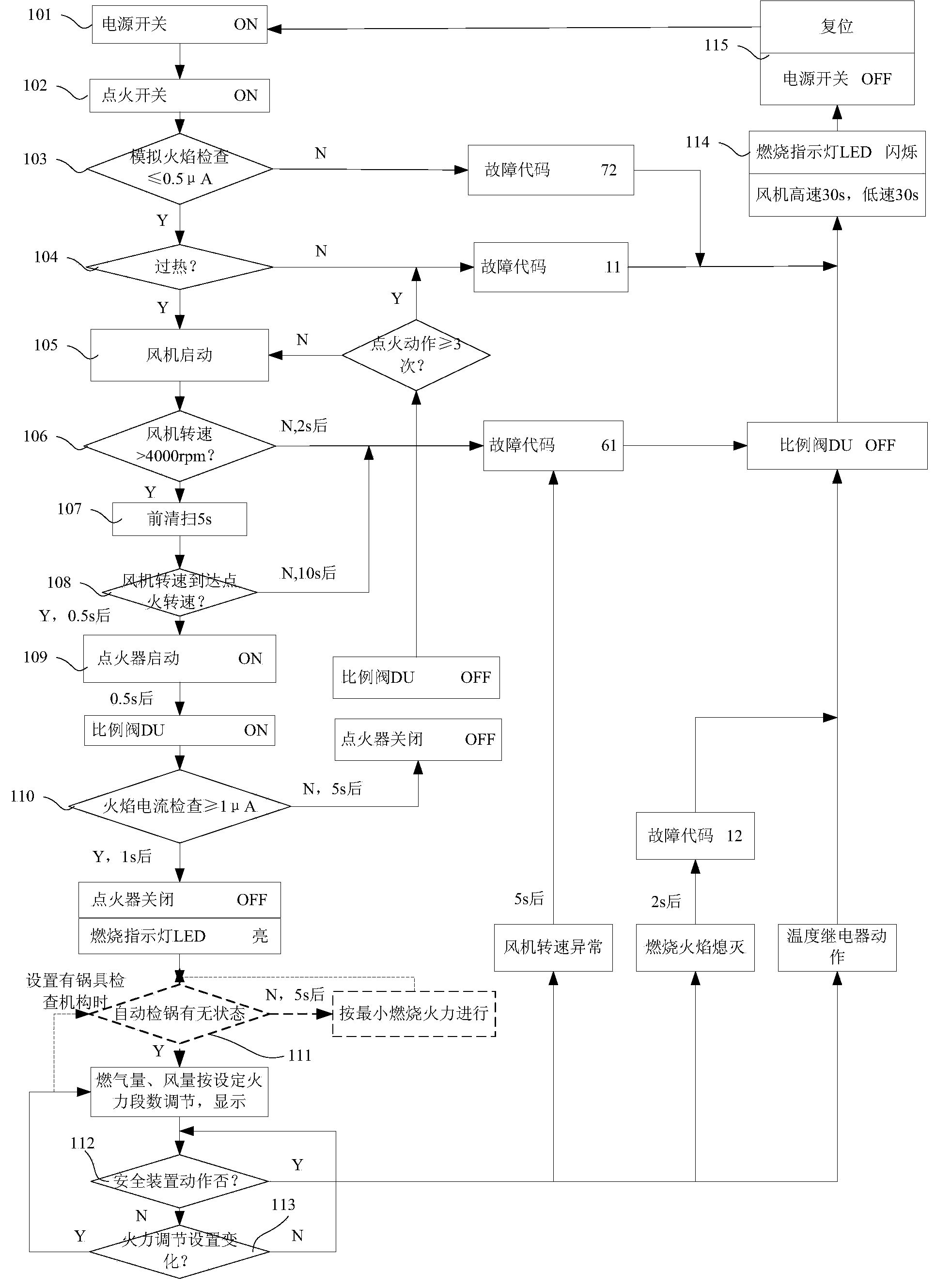

[0031] Such as figure 1 As shown, the control method includes the following steps:

[0032] Step 101, the power switch is turned on, the power indicator on the operator is on, the firepower indicator LED is displayed according to the number of unpowered segme...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that, in this embodiment, a=4000rpm in step 107, and the purge time is 0.5s.

Embodiment 3

[0053] The difference between this embodiment and Embodiment 1 is that in this embodiment, a=3000rpm in step 107, and the purge time is 12s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com