Determination method for storage life of emulsion explosive

A technique of emulsified explosives and a measurement method, which is applied in the chemical industry, can solve the problems of inability to accurately measure the storage days of explosives, and achieve the effects of short measurement period, stable and reliable data, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

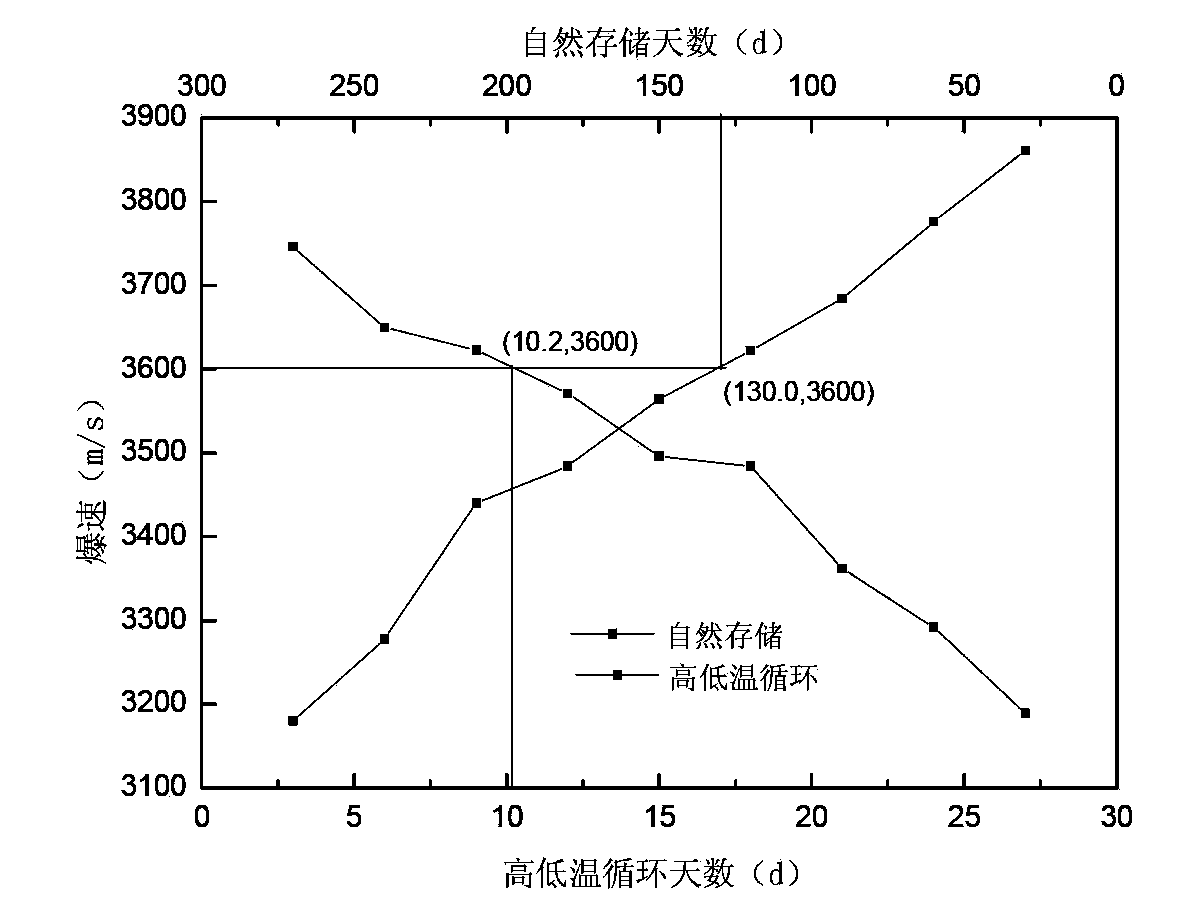

Embodiment 1

[0022] (1) Measurement of detonation velocity after high and low temperature cycle

[0023] (a) Take a series of emulsion explosives produced by an emulsion explosive factory (same components, slightly different content or production process), 18 rolls with a diameter of 32 mm and a length of 200 mm, each in a group of two.

[0024] (b) Put the above-mentioned medicinal rolls in an oil bath oven at 60°C for 8 hours, and then put them in a freezer at -15°C for 16 hours as a high and low temperature cycle. After every 3 cycles, a group of explosives is taken out for the detonation velocity test, and the average value of the detonation velocity is taken. See Table 1 for the data.

[0025] Table 1 Measurement data of detonation velocity of emulsion explosive after high and low temperature cycle

[0026]

[0027] (2) Determination of detonation velocity under natural storage conditions

[0028] Measure the detonation velocity every 30 days with the same batch of emulsion expl...

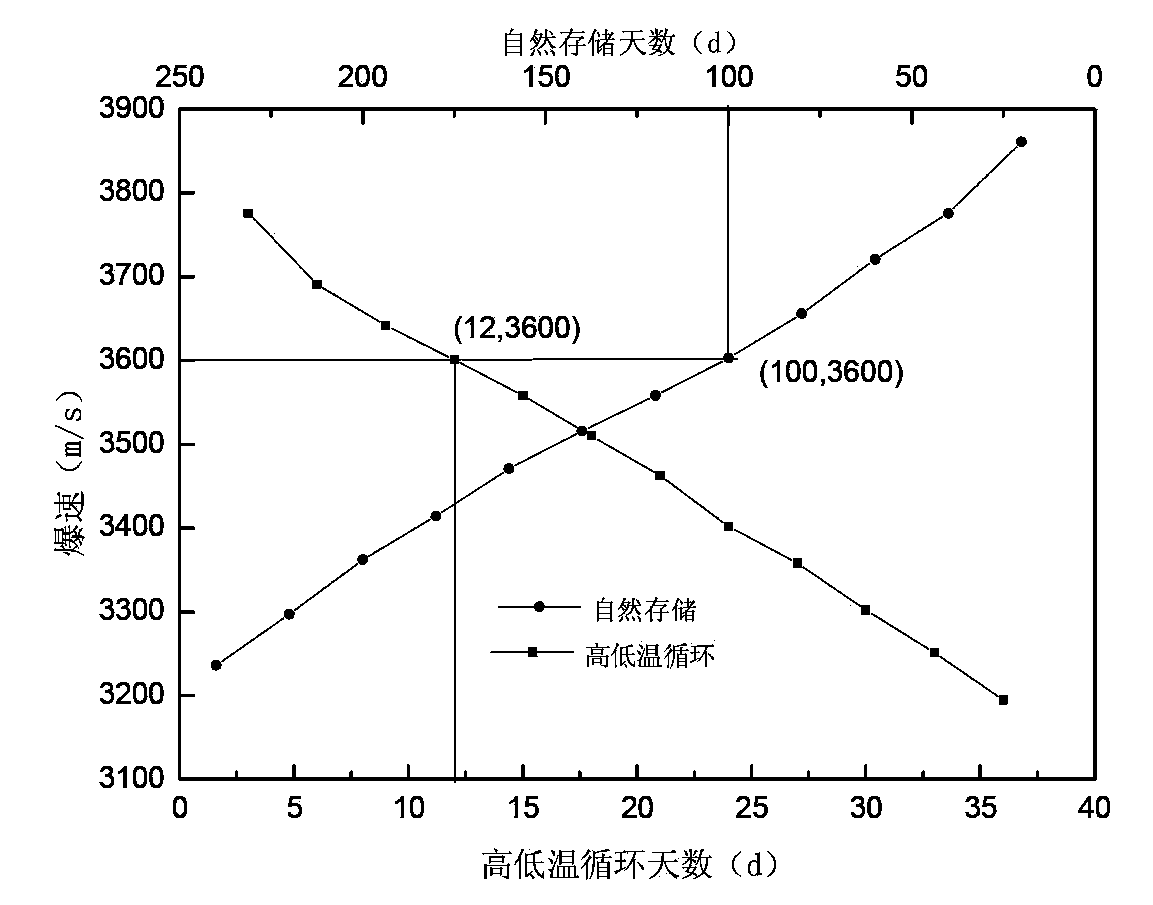

Embodiment 2

[0036] (1) Measurement of detonation velocity after high and low temperature cycle

[0037] (a) Take a certain series of emulsion explosives produced by an emulsion explosive factory (same components, slightly different content or production process), 24 rolls with a diameter of 40 mm and a length of 300 mm, each in a group of two.

[0038] (b) Put the above medicine rolls in a 50°C oil-bath oven for 8 h, and then put them in a -10°C freezer for 16 h as a high-low temperature cycle. After every 3 cycles, a group of explosives is taken out for the detonation velocity test, and the average value of the detonation velocity is taken. The data are shown in Table 4.

[0039] Table 4 Measurement data of detonation velocity of emulsion explosive after high and low temperature cycle

[0040]

[0041] (2) Determination of detonation velocity under natural storage conditions

[0042] Measure the detonation velocity every 20 days with the same batch of emulsion explosive rolls of th...

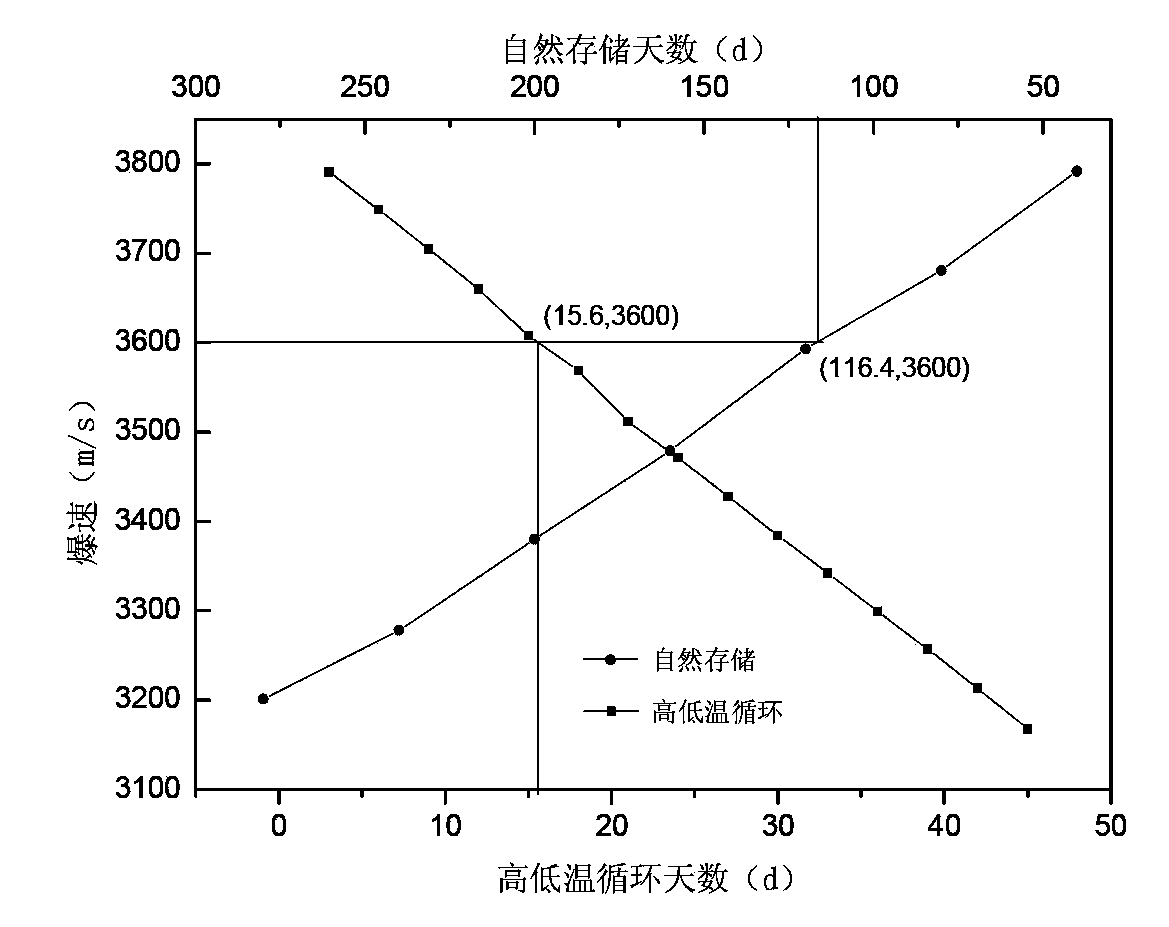

Embodiment 3

[0050] (1) Determination of detonation velocity after high and low temperature cycle

[0051] (a) Take 30 rolls of a series of emulsion explosives produced by an emulsion explosive factory (same composition, slightly different content or production process), with a diameter of 50mm and a length of 400mm, each in a group of two.

[0052] (b) Put the above medicine rolls in a 40°C oil-bath oven for 16 hours, and then put them in a -5°C freezer for 8 hours as a high-low temperature cycle. After every 3 cycles, a group of explosives is taken out for the detonation velocity test, and the average value of the detonation velocity is taken. See Table 7 for the data.

[0053] Table 7 Measurement data of detonation velocity of emulsion explosive after high and low temperature cycle

[0054]

[0055] (2) Determination of detonation velocity under natural storage conditions

[0056] Measure the detonation velocity every 40 days with the same batch of emulsion explosive rolls of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com