Fiber Coupler

A fiber optic coupling and connector technology, applied in the field of fiber optic coupling connectors, can solve problems such as improvement, limitation of the number of optical fiber arrangements, and unfavorable optical signal transmission speed, etc., to achieve the effect of increasing the number of arrangements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

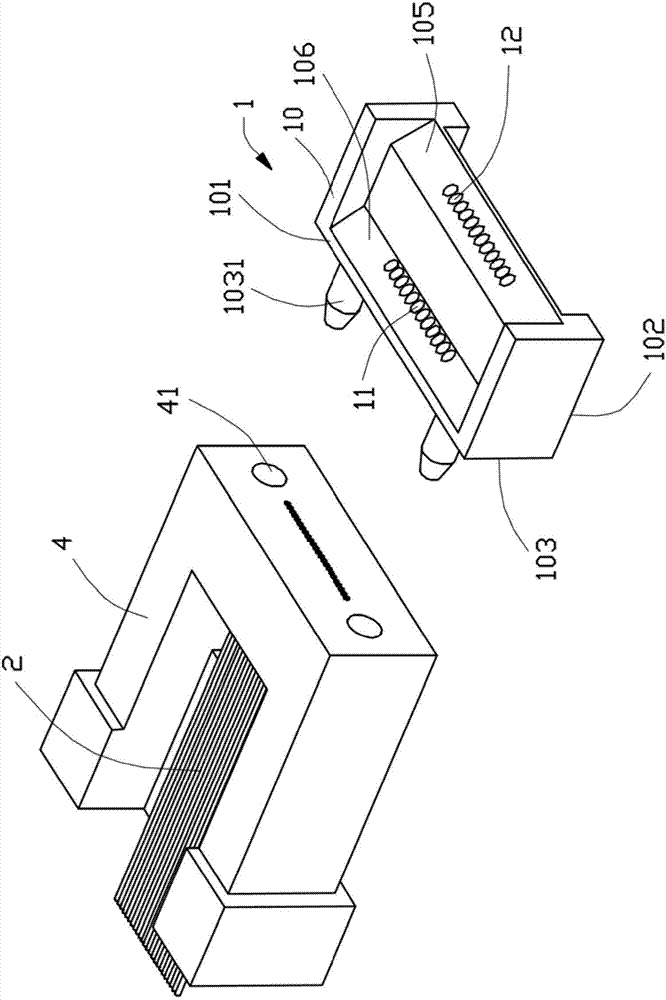

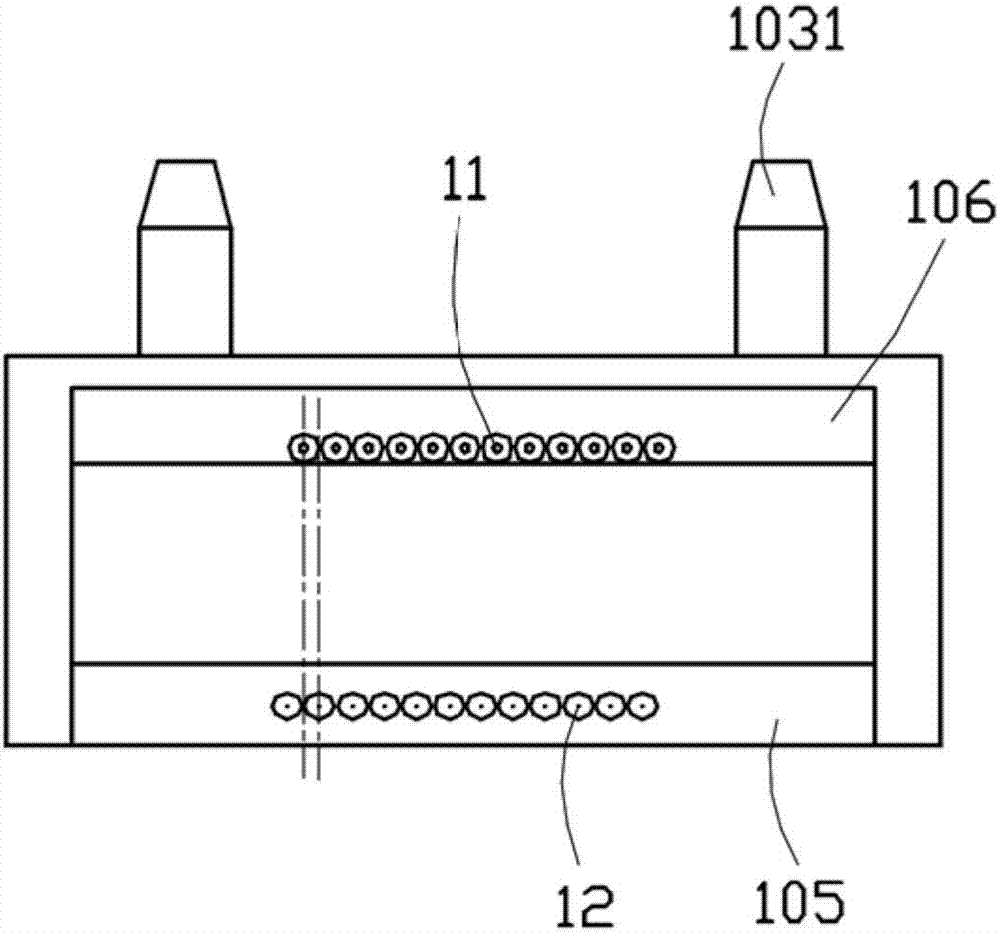

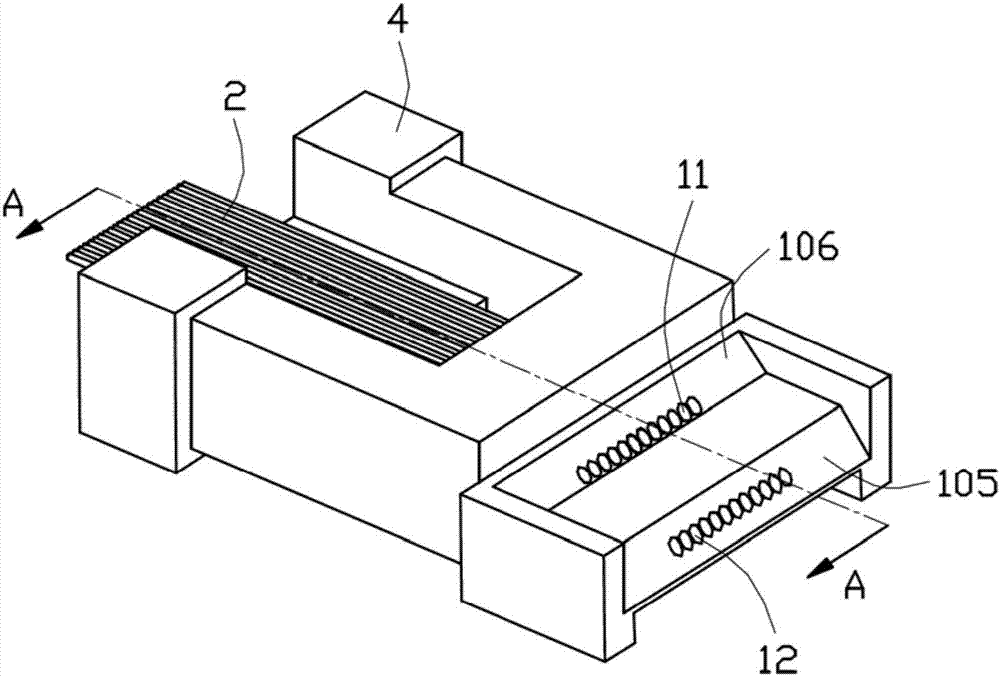

[0023] see figure 1 As shown, the optical fiber coupling connector 1 of the present invention is used for docking with the optical fiber 2 to transmit optical signals. Several second lenses 12 located in the second row. Several optical fibers 2 are fixed on the fixing base 4, and a pair of positioning holes 41 are arranged on the fixing base 4.

[0024] The plastic body 10 includes an upper surface 101 and a lower surface 102 that are parallel to each other, a front surface 103 that connects the upper surface 101 and the lower surface 102 and is perpendicular to the upper surface 101 and the lower surface 102, and forms an included angle with the front surface 103 and the lower surface 102. The first slope 106 and the second slope 105. The first inclined plane 106 and the second inclined plane 105 are arranged forward and backward. The included angle between the first slope 106 and the lower surface 102 is 45°. The first lens 11 is disposed on the first slope 106 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com