Exposure device and exposure method

A technology of exposure device and spatial light modulator, applied in the direction of photolithography process exposure device, microlithography exposure equipment, etc., can solve the problem of difficulty in increasing the power of pulsed laser, reduce the overall display time, improve the effective refresh rate, The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

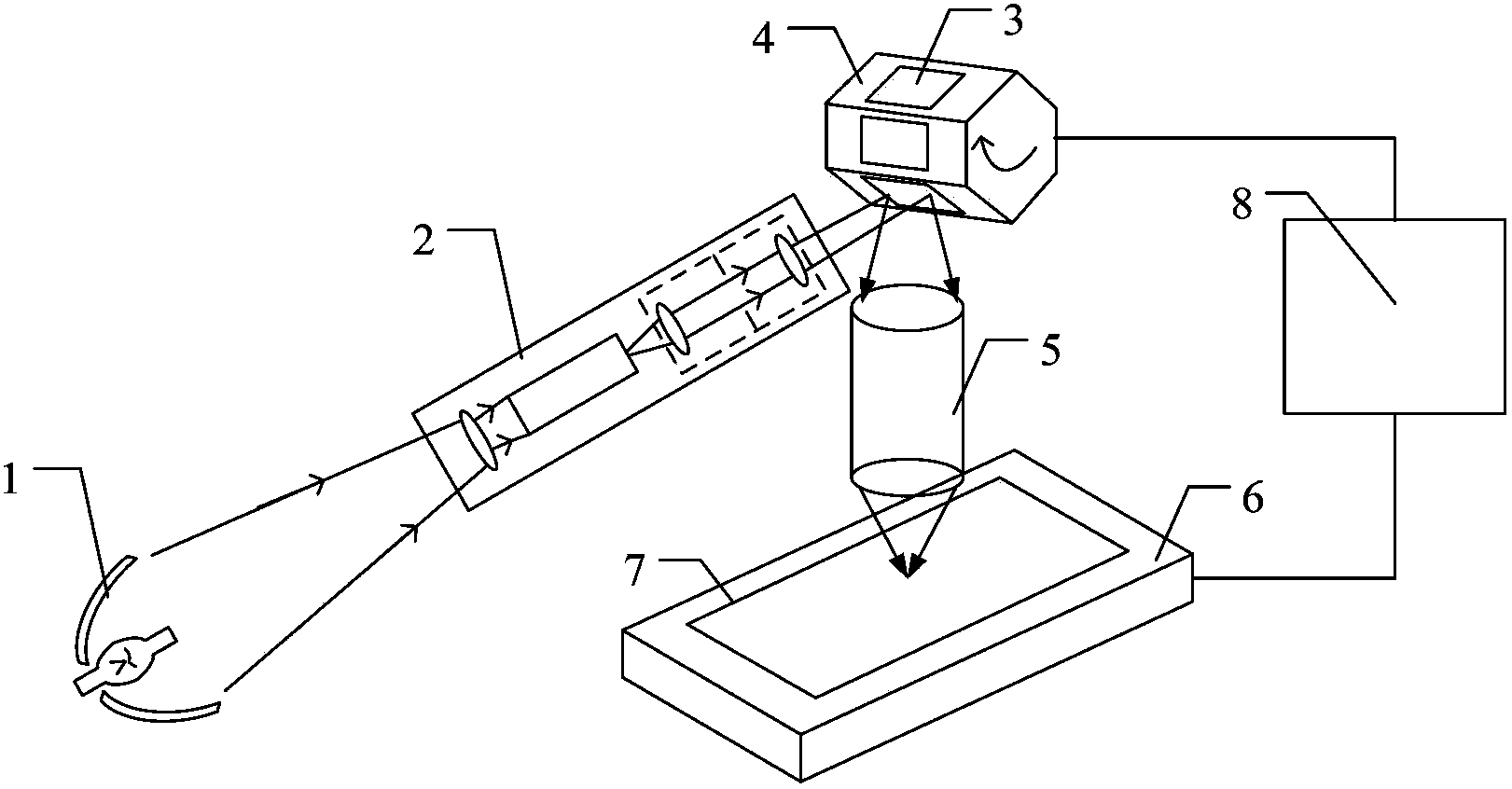

[0037] see figure 1, the exposure device provided in this embodiment is used to expose the glue-coated substrate 7 at least twice, including a light source 1, an illumination unit 2, at least two spatial light modulators 3, a motion mechanism 4, a projection objective lens 5, and a workpiece table 6 And a control unit 8, the at least two spatial light modulators 3 are installed on the motion mechanism 4 respectively, and the spatial light modulator 3, the motion mechanism 4 and the workpiece table 6 are respectively controlled by the control unit 8 control, the workpiece table 6 carrying the glue-coated substrate 7 moves to the position to be exposed under the control of the control unit 8, and the movement mechanism 4 moves the at least The two spatial light modulators 3 are sequentially adjusted to the object plane of the projection objective lens 5 for exposure, and each spatial light modulator 3 sequentially performs the data loading stage (that is, the Load state) and dev...

Embodiment 2

[0060] see Figure 7 The difference between this embodiment and Embodiment 1 is that: the moving mechanism 4 is a planar structure, and the at least two spatial light modulators 3 are arranged on the planar structure at intervals along the scanning direction. In this embodiment, the spatial light modulator 3 is a DMD, and the number of DMDs is two, which are DMD1 and DMD2, and of course the number can be set as needed. When DMD1 was brought to the object plane of projection objective lens 5, DMD1 just finished in Reset state, and began to enter the graphic display stage, and DMD2 was in Load state; when DMD1 was taken away from the object plane of projection objective lens 5, DMD2 was brought into The object plane of the objective lens 5 is projected and is in the Reset state. Theoretically, the motion mechanism 4 can drive multiple DMDs to perform reciprocating motion. Since the graphic refresh time of a single DMD is distributed to two DMDs in space, the overall frame rate ...

Embodiment 3

[0062] see Figure 8 The difference between this embodiment and Embodiment 1 is that the motion mechanism 4 is a turntable structure, and the at least two spatial light modulators 3 are distributed on the turntable structure around the center of the turntable structure. Preferably, in the exposure device of this embodiment, the at least two spatial light modulators 3 are evenly distributed on the turntable structure around the center of the turntable structure.

[0063] In this embodiment, the spatial light modulator 3 is a DMD, and the number of DMDs is 4, specifically DMD1, DMD2, DMD3 and DMD4, which uniformly rotate around a fixed shaft located at the center of the turntable structure. When DMD1 was brought to the object plane of projection objective lens 5, DMD1 just in time completed in the Reset state, and began to enter the graphic display stage, and the follow-up graphics DMD2, DMD3, DMD4 were in the Load state, only to be rotated to effective positions, due to the sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com