Tea leaf dry-roasting control method and device

A control method and a technology of a control device, applied to electrical program control, program control in sequence/logic controllers, drying, etc., can solve problems such as damage to the quality of tea leaves, easy agglomeration, and difficulty in achieving effective frying of tea leaves. To achieve the effect of improving the effect and the quality of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the invention, and are not intended to limit the scope of the present invention.

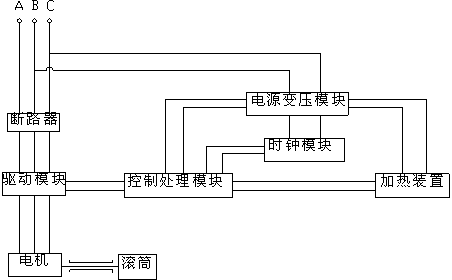

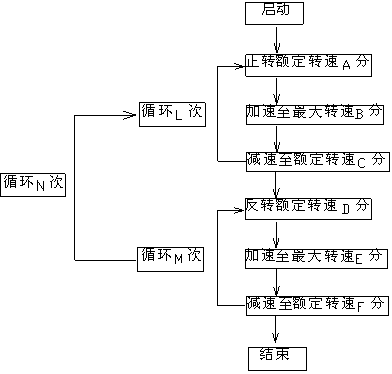

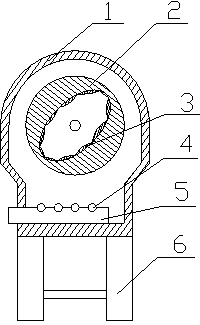

[0014] A tea frying control method (for details, see figure 1 and figure 2 ), the control method includes three-phase power supply, which provides working voltage to the drive module; circuit breaker, which is used to cut off the power supply when the drive motor circuit fails; the drive module, which supplies the working power to the motor drive; The processing module is used to receive the signal of the clock module, control the forward and reverse rotation, acceleration and deceleration of the driving module, and control the heating of the heating device; the heating device heats the furnace body; the motor drives the drum to run. Its working steps are three-phase power supply to the control drive module through the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com