Method for detecting package damage of industrial products

A technology for damaged packaging and industrial products. It is used in optical testing flaws/defects, image data processing, instruments, etc., and can solve problems such as damaged packaging, incomplete thermoplastics, and occupation of labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

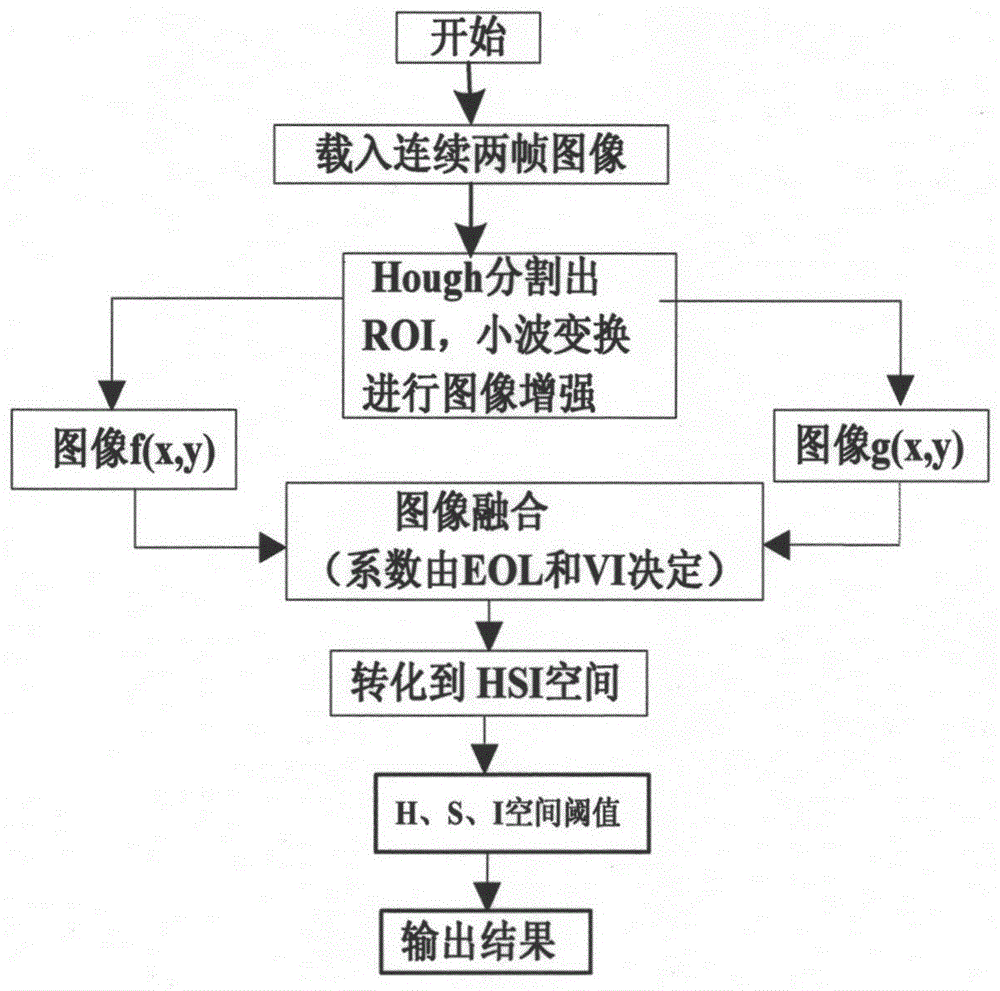

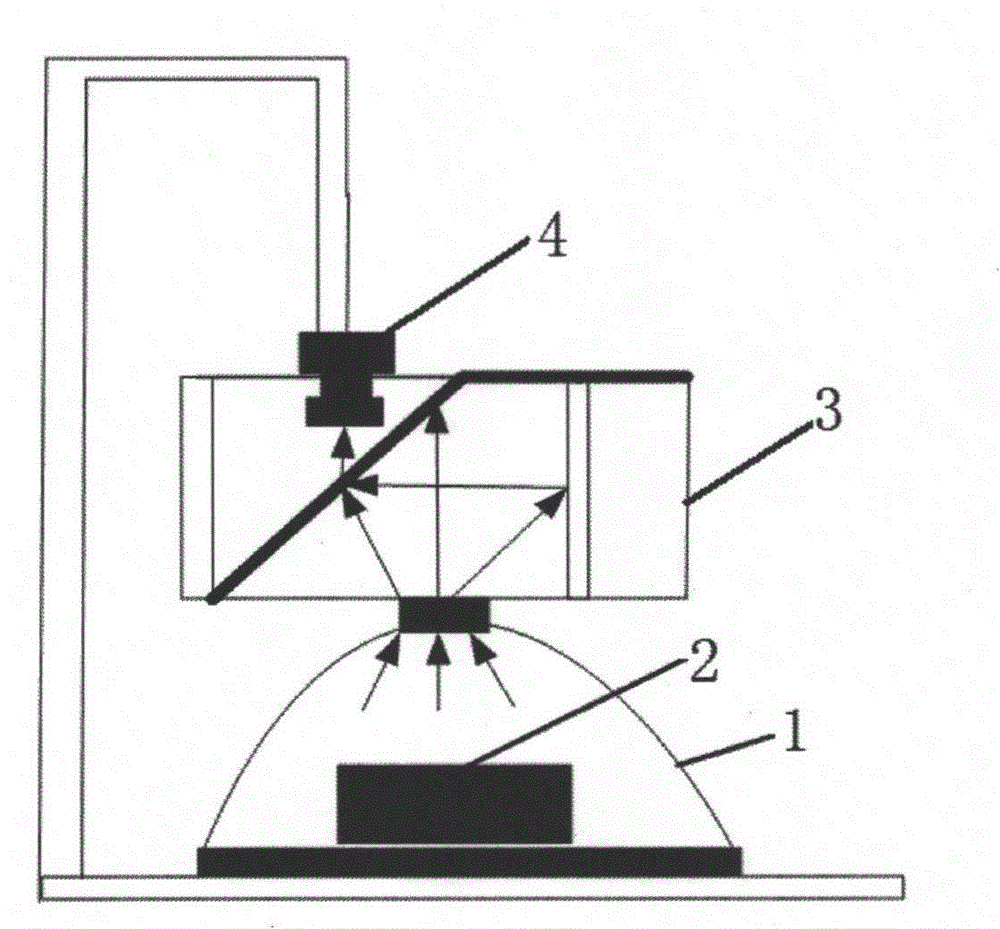

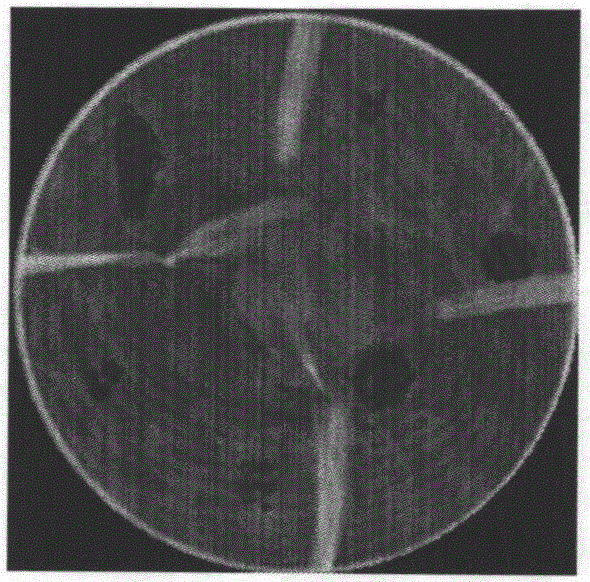

[0040] combine figure 1According to the characteristics of the shooting environment and the packaging film, the method for detecting the damage of industrial product packaging provided by the present invention adopts a special shooting light source and obtains a relatively good shooting effect. When performing detection, a digital image processing system is proposed. Instead of traditional hardware detection, the combination of Hough transform, wavelet transform and image fusion reduces running time and improves execution efficiency and detection accuracy. First, image preprocessing is performed on the thin film, Hough transform is used to segment the region of interest, and wavelet transform is used to enhance the image contrast, and then the Laplace energy EOL of each pixel and the local gray contrast VI of the region of interes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com