Double-core cable for pipeline

A twin-core cable and pipe technology, which is applied in the field of power cables, can solve the problems of high manufacturing and construction costs, thick cables, and reduced bending performance, and achieve the effects of superior heat resistance, improved flexibility, and improved processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

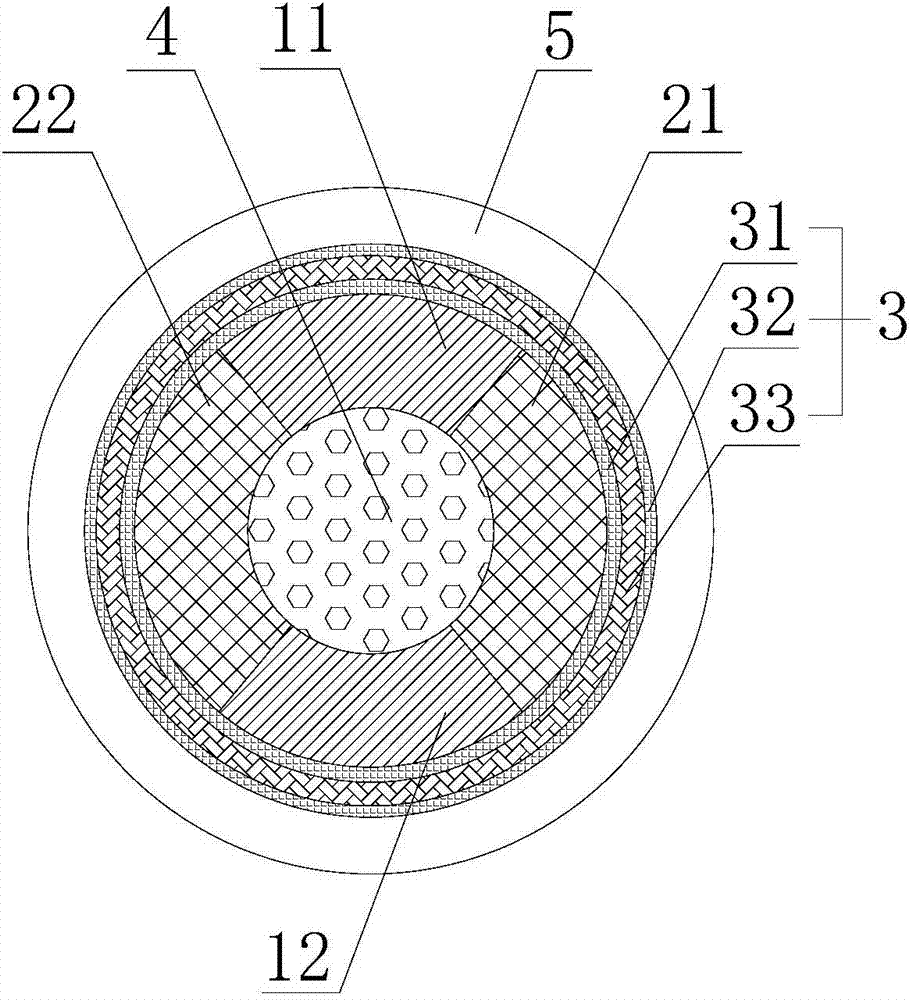

[0012] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a twin-core cable for pipelines proposed by the present invention.

[0013] refer to figure 1 , a twin-core cable for pipelines proposed by the present invention includes a central strengthening member 4 made of glass fiber bundles at the core, and a first conductor 11, a second conductor 12, and a first insulator are arranged on the outer periphery of the central strengthening member 4. 21. The second insulator 22, the first conductor 11, the second conductor 12, the first insulator 21, and the second insulator 22 are close to the central reinforcement 4, and the first conductor 11, the first insulator 21, and the second conductor 12. The second insulator 22 is connected sequentially. On any cross-section, the upper and lower surfaces of the first conductor 11, the second conductor 12, the first insulator 21, and the second insulator 22 face the central reinforcement 4 The center of the cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com