Manufacturing method of electric locomotive transformer oil pump wiring board

A technology for electric locomotives and manufacturing methods, which is applied to the assembly/disassembly of contact parts, electrical components, electromechanical devices, etc., and can solve problems such as uneven injection pressure, oil leakage from terminal posts, gas gaps between terminal boards and terminal posts, etc., to achieve Simple processing, prevent leakage, and improve insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

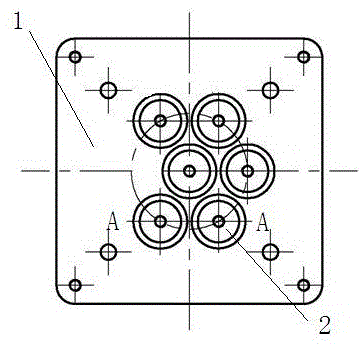

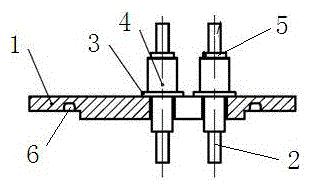

[0030] Such as figure 1 , figure 2 As shown, the electric locomotive transformer oil pump terminal board includes an upper metal part 5, a 95-alumina ceramic body 4, a lower metal part 3, a metal terminal post 2 and a metal terminal board 1, and the metal terminal board 1 is made of No. 45 steel or Q235A steel plate , the metal terminal 2 is made of No. 45 steel, which is easy to process and low in cost; there is a mounting hole on the metal terminal plate 1, and the ninety-five alumina ceramic body 4 is inserted in the installation hole, and the metal terminal 2 is inserted in the ninety-five alumina Inside the ceramic body 4 and protruding from both ends of the 95-alumina ceramic body 4, the upper metal part 5 is arranged between the top of the 95-alumina ceramic body 4 and the metal terminal 2, and the lower metal part 3 is arranged on the 95-alumina ceramic body 4 and the metal terminal board 1; the metal terminal 2, the upper metal part 5, the ninety-five alumina cerami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com