Electrical cabinet of cab

A technology for electrical cabinets and driver's cabs, applied in the field of electrical cabinets, can solve the problems of maintainability, poor aesthetics, horizontal and vertical wiring harnesses, and low space utilization, so as to achieve clear and reasonable wiring harness arrangement, easy debugging and Reasonable effect of maintenance and equipment arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

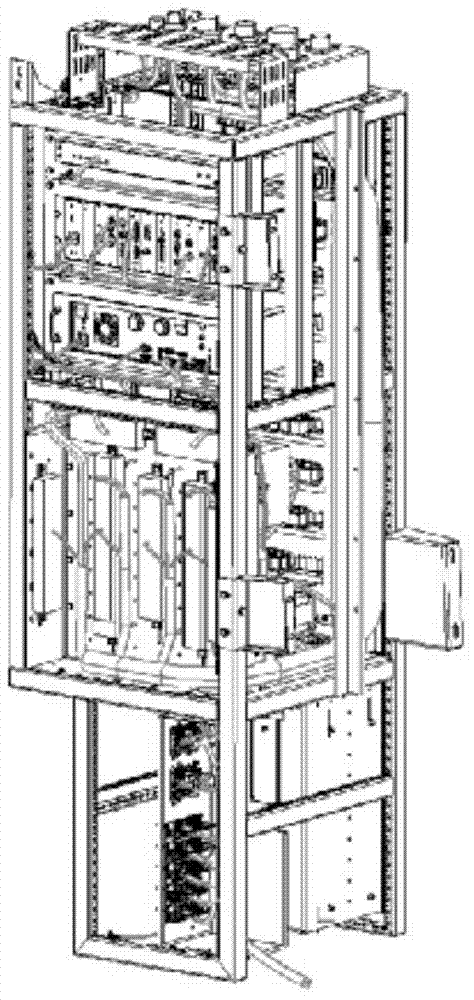

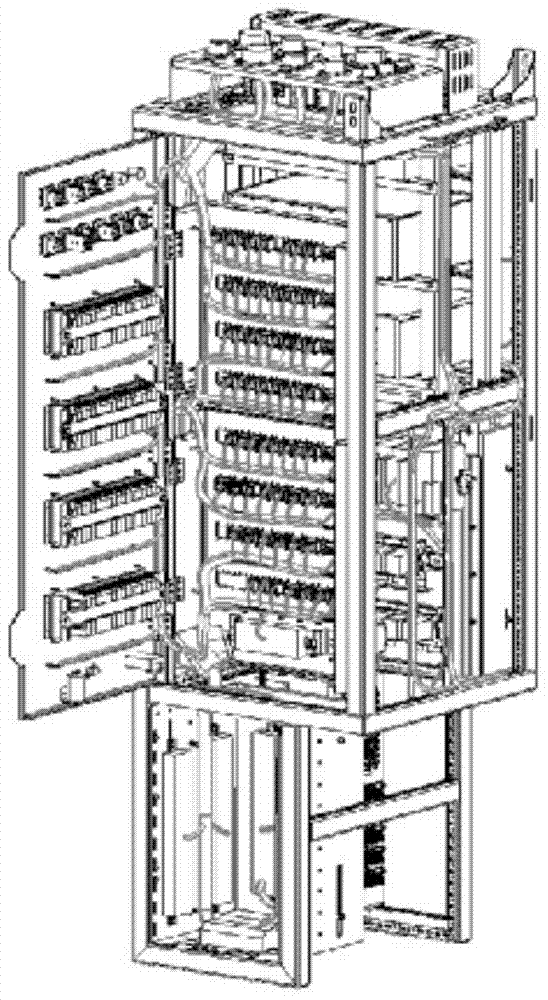

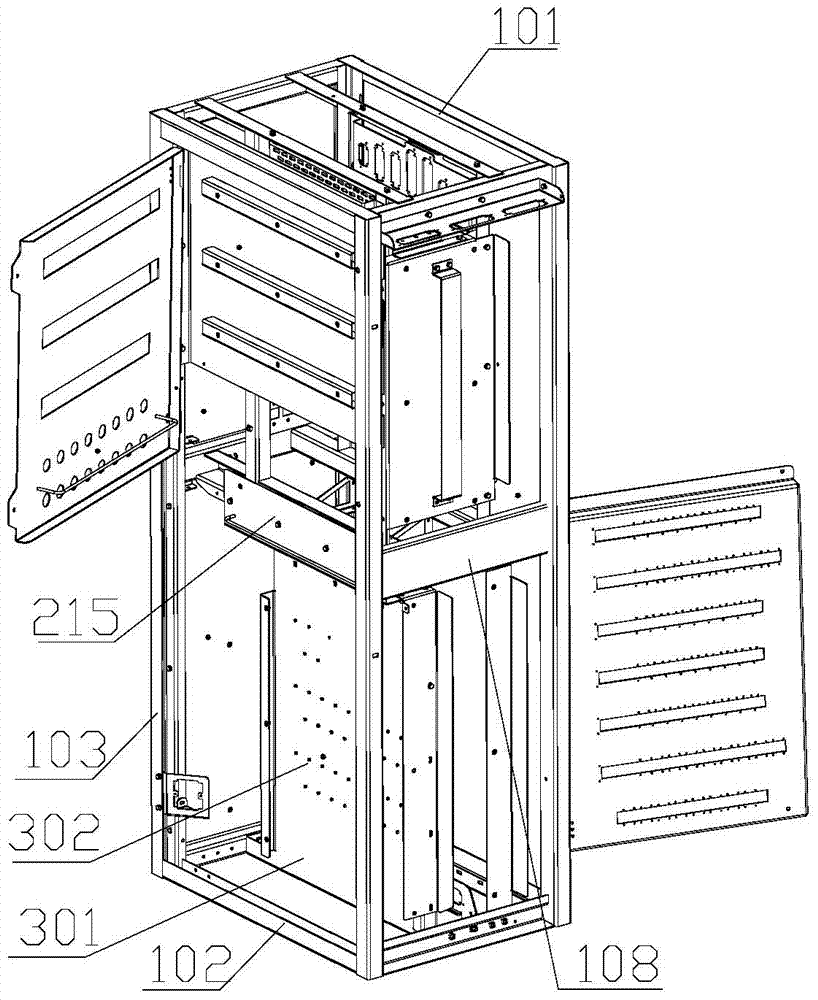

[0020] A kind of cab electric cabinet of this embodiment, such as Figure 3-7 As shown, it includes a rectangular parallelepiped outer frame composed of a rectangular top frame 101, a rectangular bottom frame 102, and four parallel columns 103. The four longitudinal sides of the outer frame are respectively a front frame 104, a back frame 105, and a first side frame 106. And the second side frame 107, the middle part of the first side frame 106 and the second side frame 107 is provided with the waist beam 108 perpendicular to the column, and the first side frame 106 is divided into the first upper side frame 109 and the first side frame 109 by the waist beam 108. The lower side frame 110, the second side frame 107 is divided into the second upper side frame 111 and the second lower side frame 112 by the waist beam 108, the front frame 104 has at least two first top rails 201 parallel to each other, two Between the waist crossbeams 108 are fixed two mutually parallel first inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com