High-torque disc type permanent magnet reduction gear

A reduction gear, high-torque technology, applied in electrical components, generators/motors, etc., can solve problems such as difficulty in transmitting high torque, and achieve the effect of high magnetic energy utilization and improved magnetic energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

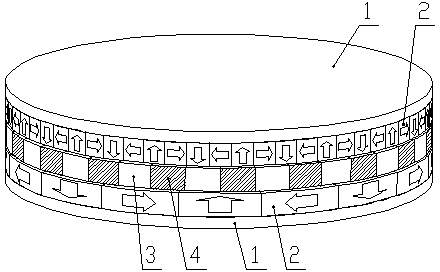

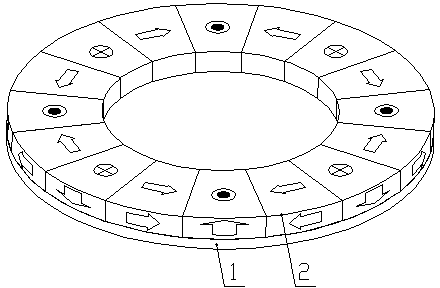

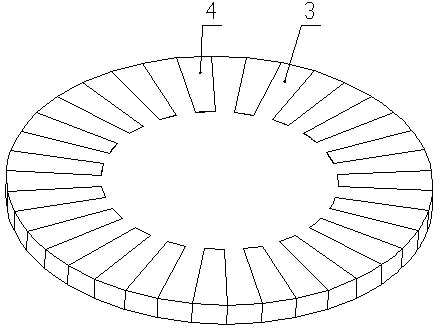

[0032] like Figure 1-Figure 16 As shown, the high-torque disc permanent magnet deceleration device of the present invention includes a coaxial and sequentially installed first permanent magnetic disc assembly, a modulation disc assembly and a second permanent magnetic disc assembly, and there is a gap between adjacent two assemblies. The gap between the first permanent disk assembly and the reticle assembly is called the primary air gap, and the gap between the reticle assembly and the second permanent disk assembly is called the secondary air gap;

[0033] Both the first permanent magnetic disk assembly and the second permanent magnetic disk assembly include a disk-shaped yoke 1 and a permanent magnet 2, and the permanent magnets 2 are evenly distributed on the inner surface of the disk-shaped yoke 1 along the central circumferential direction of the disk-shaped yoke 1, The modulation disk assembly is located between the permanent magnet 2 of the first permanent disk assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com