Portable adaptive egg baker

An egg roaster and self-adaptive technology, applied in the field of egg roasters, can solve the problems of limiting the portability of the egg roaster, difficult to achieve portability, portability discount, etc., to achieve improved portability and versatility, easy disassembly, convenient The effect of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

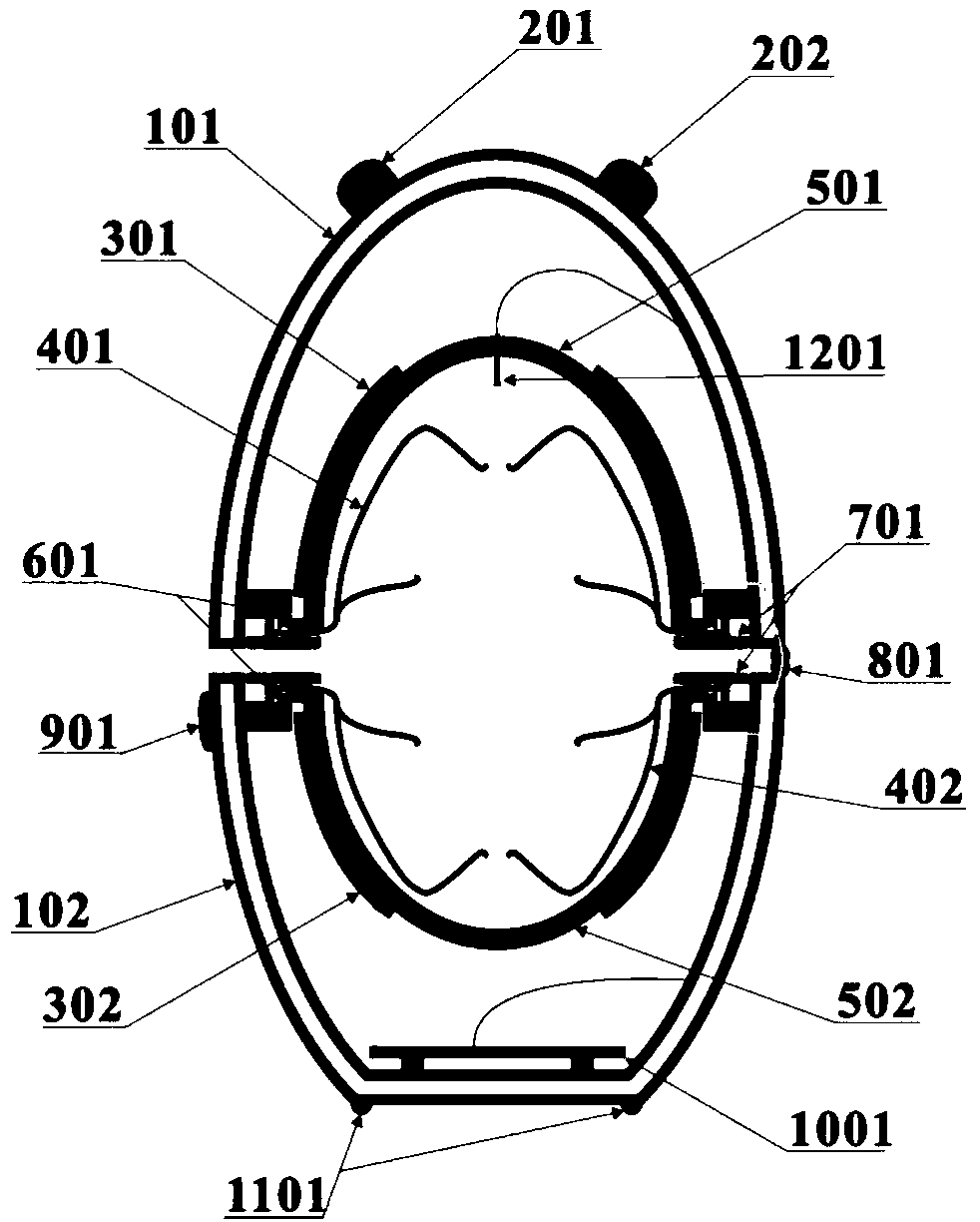

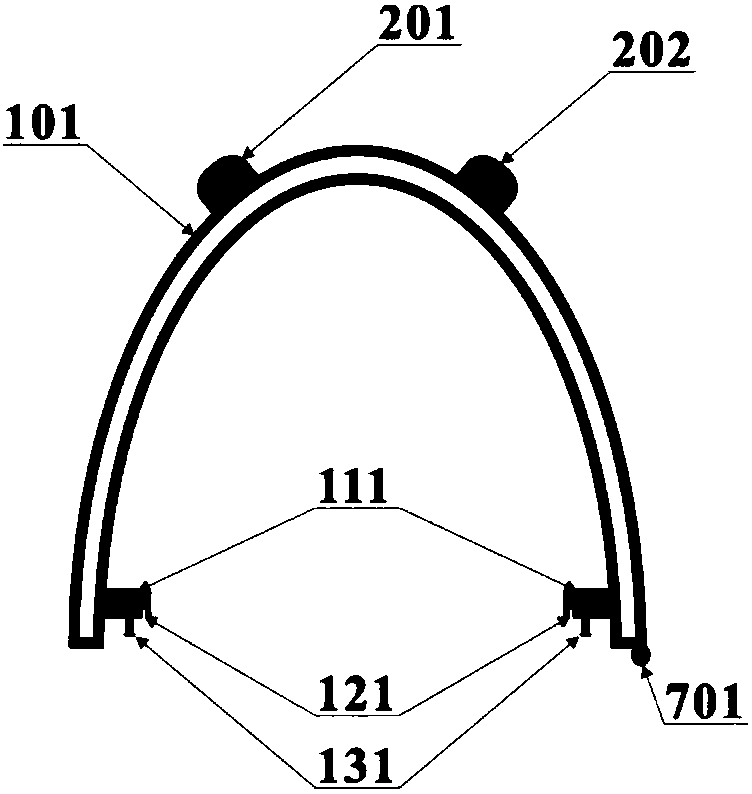

[0042] In the first embodiment, the mouth edges of the upper shell 101 and the lower shell 102 have two or more symmetrical and integral inward protrusions 111, and each protrusion 111 is provided with an upper liner 501 and a lower liner 502. The screw hole 121 and the fixing nail 131 for fixing the upper elastic bracket 401 and the lower elastic bracket 402.

[0043] The upper liner 501 and the lower liner 502 are fixed on the mouth edges of the upper shell 101 and the lower shell 102 through the screw holes 121 by screws 601. The outer edges of the upper elastic bracket 401 and the lower elastic bracket 402 are fixed to the fixing nails 131 of the housing 101 and 102 through respective notches. Flexible support such as Figure 3 to Figure 7 Shown.

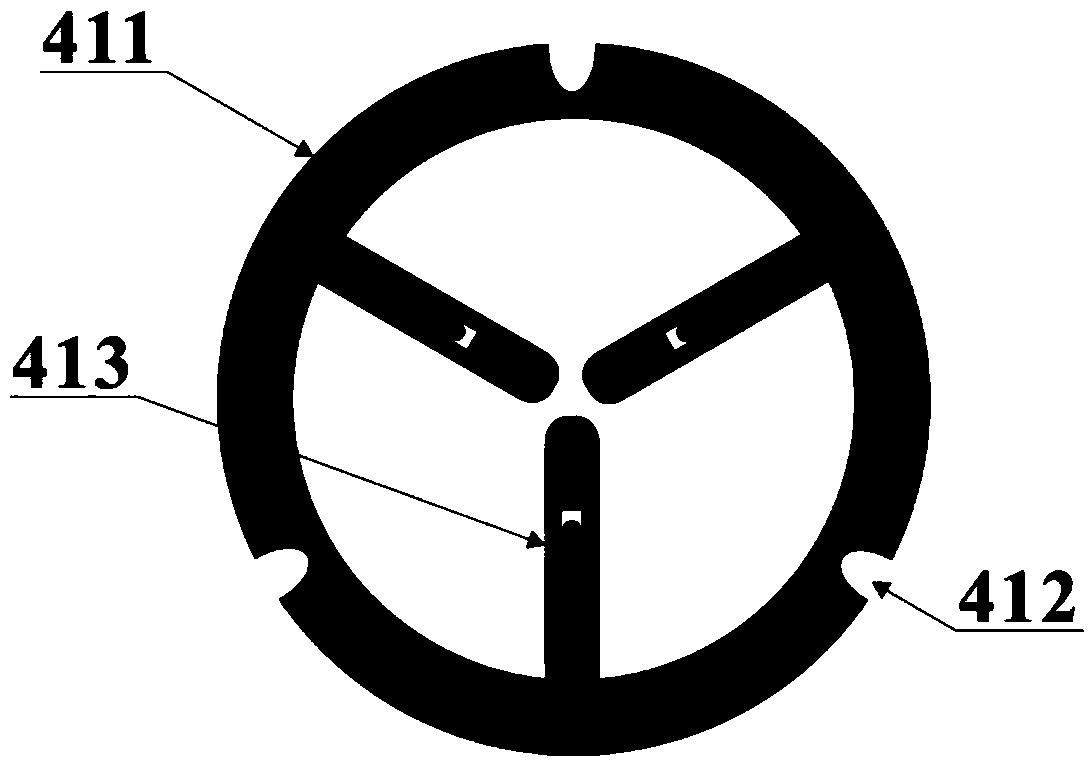

[0044] The elastic support in this embodiment has the following three preferred solutions:

[0045] As a preferred option one, such as image 3 , Figure 4 Shown. The outer edge 411 and the notch 412 on the outer edge are fixed to ...

Embodiment 2

[0048] Example two, such as Picture 8 As shown, in this embodiment, there is a small protrusion 512 at the bottom of the upper liner 501 and the lower liner 502 for fixing the elastic support. In this case, a small hole for passing through the temperature measuring element 1201 is opened on the upper side of the upper inner liner 501, and the small protrusion 512 is preferably not hindered. The upper elastic support 401 and the lower elastic support 402 can be directly fixed on the small protrusions 512 of the upper inner liner 501 and the lower inner liner 502. When in use, the heated egg can be directly placed on the elastic support 442. After the entire egg roaster is closed, the elastic support 442 is squeezed and compressed by the egg in the inner container. One or more sets of such elastic supports can provide good elastic support for the heated eggs inside. Picture 8 It is only an embodiment, and the elastic support may not be such a tower spring but a spring of other...

Embodiment 3

[0057] In the third embodiment, the control key controls the heating process (such as heating mode, temperature and time) in the form of a touch panel.

[0058] After the upper inner container 501, the lower inner container 502, the upper heating unit 301, the lower heating unit 302, the upper elastic support 401, the lower elastic support 402, and the power supply board 1001 are respectively assembled on the upper housing 101 and the lower housing 102, the upper and lower parts can be used It is connected by a hinge 801 on the shell, which is convenient for opening and closing.

[0059] After the inner container is closed, a closed container that can contain one or more eggs is formed. The self-adaptive system can be compressed to different degrees according to the size of different eggs, thereby playing the role of elastic support and cushioning for the eggs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com