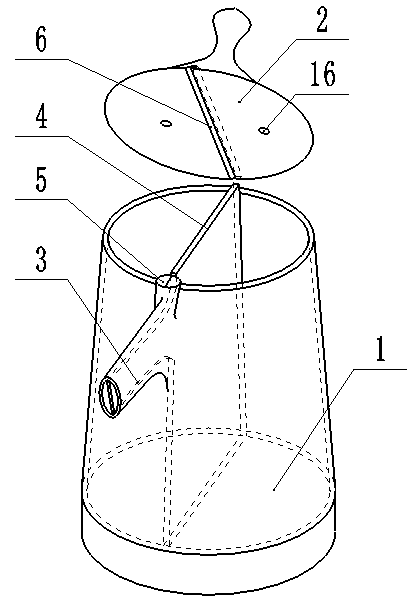

Vinegar and soy sauce integral kettle

A technology for soy sauce and body pot, which is applied in the field of kitchen utensils, can solve the problems of a lot of things occupying an area, a messy kitchen, etc., and achieves the effects of preventing evaporation or mutual smell, being simple and convenient to use, and preventing the lid from shifting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

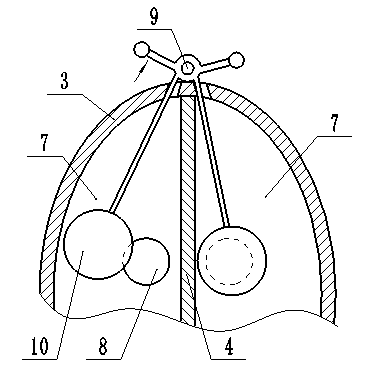

[0032] Such as figure 2 The dumping switch 5 shown is a rotary integrated self-recovery switch;

[0033] The structure of the rotary integrated self-restoring switch is as follows: an isolation plate 7 is provided in the two flow channels of the pouring port 3, and a liquid flow hole 8 is opened on each isolation plate 7, and the upper end of the pouring port 3 is hinged by a self-recovering spring There is an X-shaped rotary switch 9, the two rotary rods on the upper part of the rotary switch 9 are located outside the pouring port 3, and the two connecting rods on the lower part of the rotary switch 9 extend into the two flow channels of the pouring port 3 respectively, and a covering liquid is provided at the end A first baffle 10 of the flow hole 8;

[0034] Both liquid flow holes 8 are arranged close to the separator 4 .

[0035] How to use: Pull up one of the rotary rods, the liquid in the corresponding cavity flows out, and the first baffle plate 10 in the opposite fl...

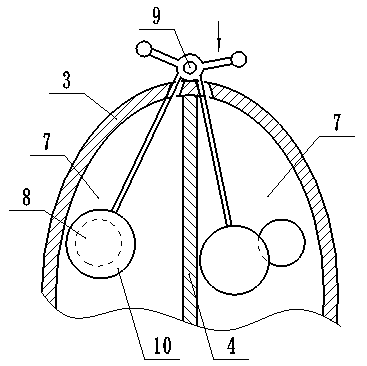

Embodiment 2

[0037] Such as image 3 As shown, the structure of the pouring switch 5 is the same as that of the first embodiment, and the two liquid flow holes 8 are arranged near the inner wall of the pouring port 3 .

[0038] How to use: Press down one of the rotary rods, the liquid in the corresponding cavity flows out, and the first baffle plate 10 in the opposite flow channel blocks the liquid flow hole 8 .

Embodiment 3

[0040] Such as Figure 4 The dumping switch 5 shown is a rotary sub-control type self-recovery switch;

[0041] The structure of the rotary sub-control type self-recovery switch is as follows: an isolation plate 7 is provided in the two flow channels of the pouring port 3, and each isolation plate 7 is provided with a liquid flow hole 8, and two L-shaped lever switches 11 Symmetrically installed and the knuckles are hinged on the upper end of the pouring port 3 through a self-restoring spring. Each lever switch 11 is located outside the pouring port 3, and the other side rod extends into the corresponding flow channel and is provided with a cover at the end The second baffle plate 12 of the liquid flow hole 8 .

[0042] How to use: press down one of the outer side rods, the liquid in the corresponding cavity flows out, and there is no change in the second baffle plate 12 in the relative flow channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com