Paper bag machine

A paper bag machine and paper roller technology, applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of reduced edge sealing efficiency, chaotic paper conveying, limited clamping force, etc., to improve production efficiency and improve efficiency , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

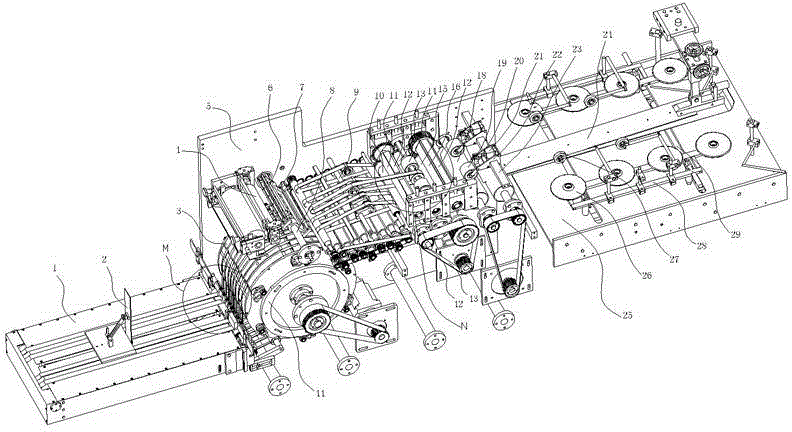

[0020] Referring to the accompanying drawings, this kind of paper bag machine includes a forming mechanism, a feeding mechanism, a breaking mechanism, an edge sealing mechanism and an output mechanism arranged on the frame 5 in sequence, and also includes a The batch organization:

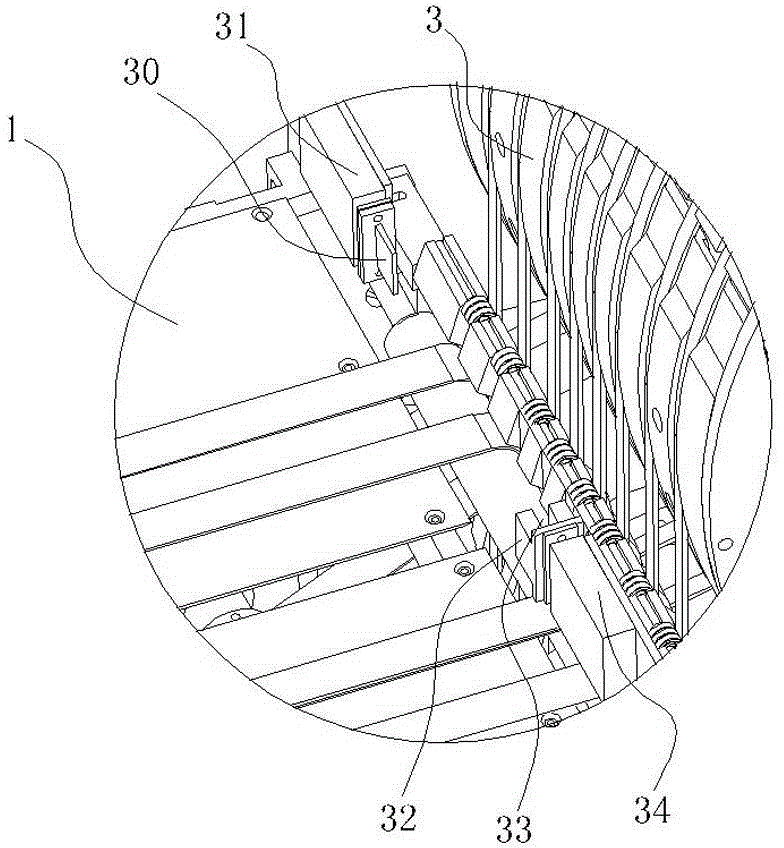

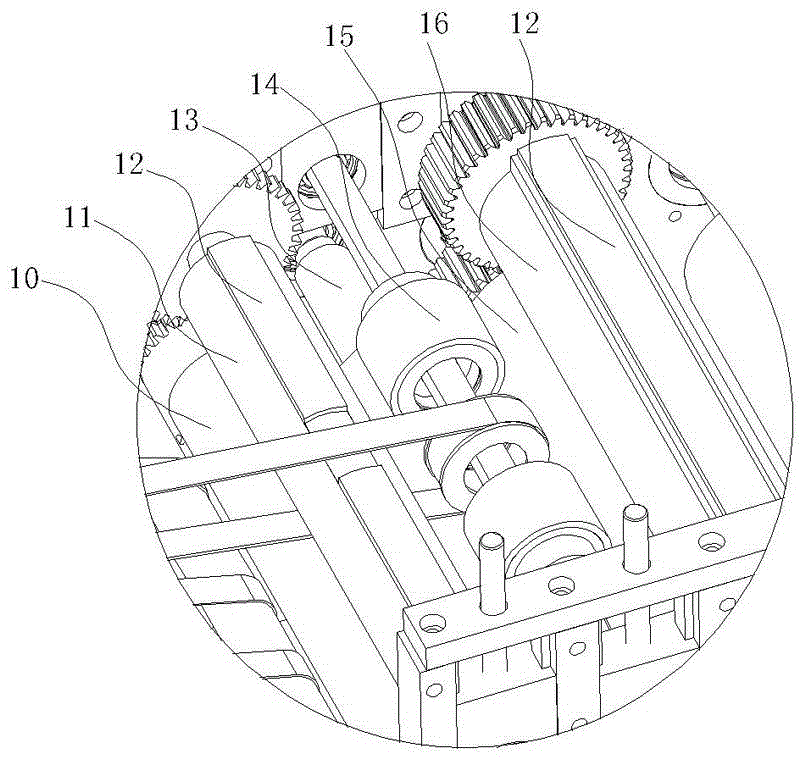

[0021] Described molding mechanism comprises working platform 25 and is located at the folding board 24 on working platform 25, press paper wheel 27 and top paper turntable 26, the width of described paper folding board 24 upper strata board is less than the width of lower deck, described press paper wheel 27 and the top paper turntable 26 are respectively located above and on both sides of the folding board 24, and the pressure roller 27 and the top paper turntable 26 are slidably arranged on the working platform 25 through the mounting frame 28. Specifically, the mounting frame 28 The support passes through the chute 29 on the working platform 25 and is connected with the slide bar located at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com