Automatic winding roll

An automatic reeling and reeling technology, applied in the field of reels, can solve the problems of unfavorable manufacturing cost and reliability, complex brake and release structures, and complex parts structures, etc., and achieves high commercial value, simple structure, and simple assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific examples.

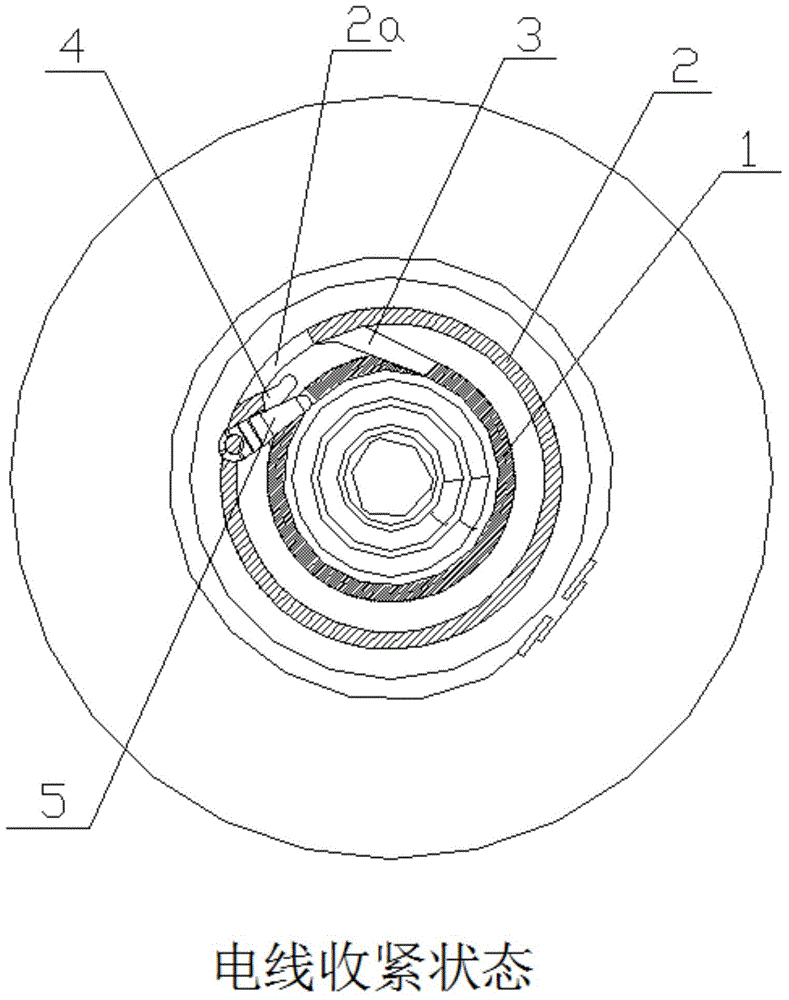

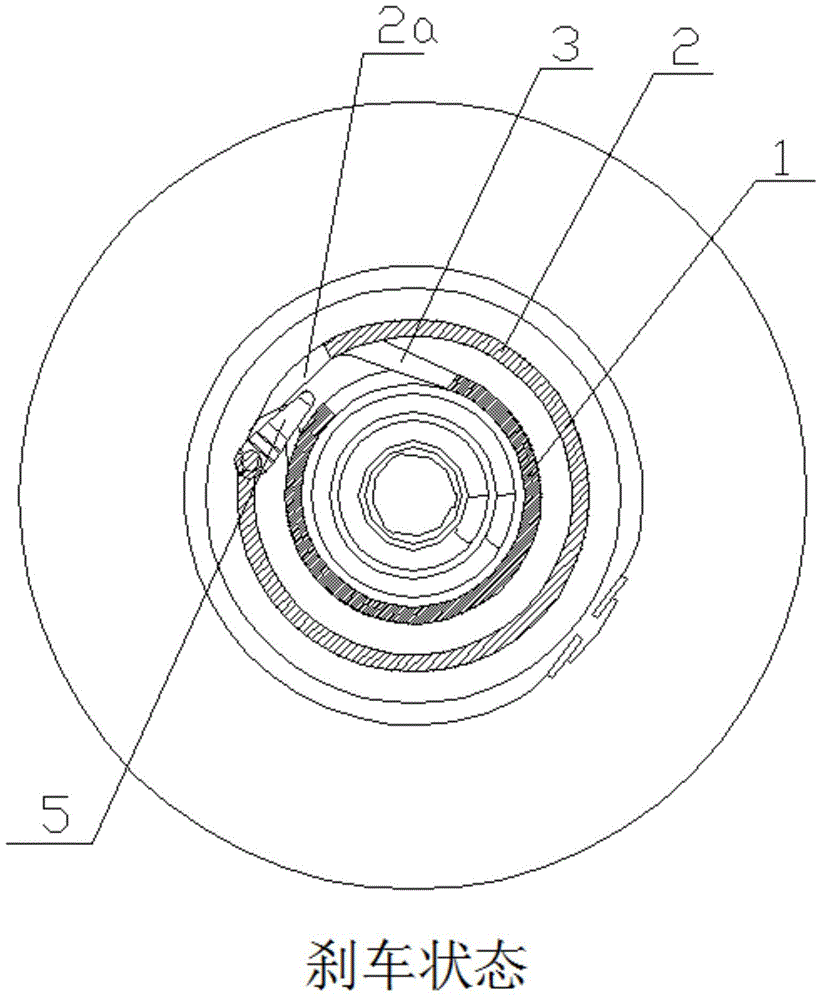

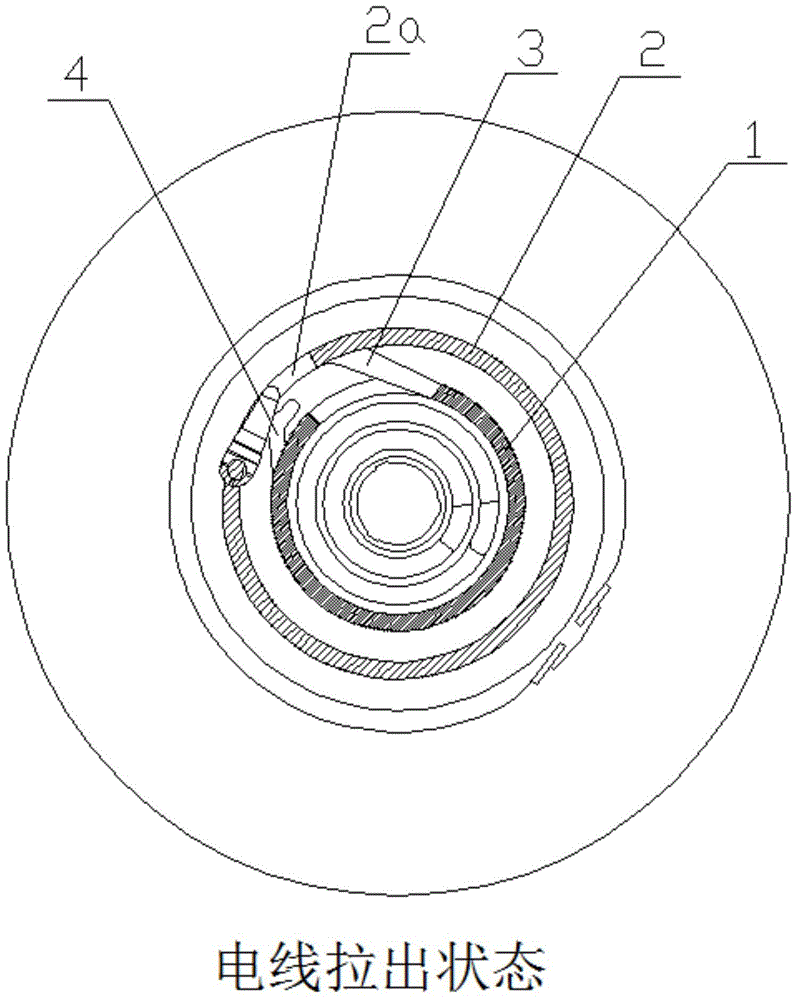

[0025] see Figure 1-3 , a kind of automatic reel, the reel wound on the automatic reel is subjected to the external force of automatic roll-up under the action of the elastic recovery mechanism, and the inner ring groove 1, the outer ring groove 2. The clamping rod 5, the protruding head of the clamping rod 5 is stuck in the inner and outer ring grooves 1 and 2 and slides along it; The trajectory direction is outward, otherwise it is inward; the inner ring groove 1 is smoothly connected with the outer ring groove 2 through the connecting groove 3, and there is a step I at the side of the connecting groove 3 adjacent to the inner ring groove, and the connecting groove 3 Located at the lower level of the step I; the connecting position of the outer ring groove 2 and the connecting groove is outward, passing through the first section 2a of the outer ring groove, and a step II i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com