Sponge iron elevator of powder metallurgy reduced iron powder industry and system

A technology of reducing iron powder and powder metallurgy, which is applied in the direction of furnaces, furnace types, fluidized bed furnaces, etc., can solve the problems of increasing magnetic separation load, large area occupied by system equipment, and large equipment occupied area, so as to facilitate maintenance Effects of maintenance, space saving, and effective use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

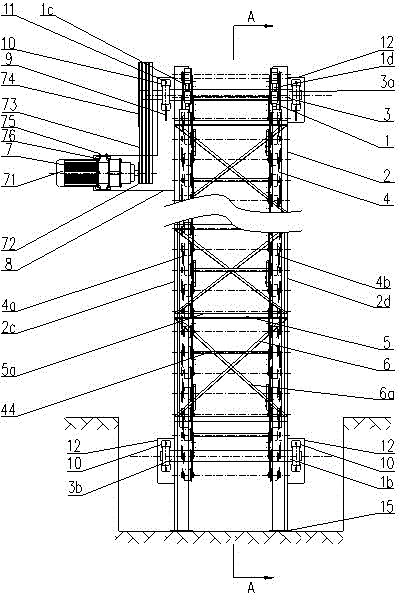

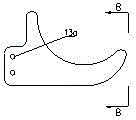

[0045] refer to figure 1 , figure 2 , Figure 3a , Figure 3b , Figure 4 , Figure 5 , Figure 6a , Figure 6b , Figure 6c , Figure 7 Make the invention.

[0046] The sponge iron hoist includes a hoist reversing sprocket 1 and a hoist frame 2, the hoist reversing sprocket 1 is composed of an upper reversing sprocket 1a and a lower reversing sprocket 1b, the upper reversing sprocket 1a, The left sprocket 1c and the right sprocket 1d are respectively arranged on the lower reversing sprocket 1b and are respectively fixed on the sprocket shaft 3; It is connected by the left long-pitch roller chain 4a and the right long-pitch roller chain 4b.

[0047] The hoist frame 2 is composed of an upper frame 2a and a lower frame 2b. Both the upper frame 2a and the lower frame 2b are composed of a left frame 2c and a right frame 2d. The upper frame 2a is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap