Noise reducing device, manufacturing method thereof and freezer

A noise reduction and refrigerant technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as poor noise reduction effects, achieve the effects of improving hearing, solving eruption noise, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

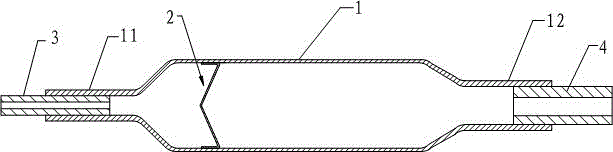

[0032] refer to figure 2 As shown, a noise reduction device includes a pipe body 1. A conical cap 2 is provided inside the pipe body 1. Both ends of the pipe body 1 have necks 11 and 12, and one end of the neck 11 is connected to the refrigerant inlet. The tube 3 has a constricted port 12 at the other end to connect the refrigerant outlet tube 4.

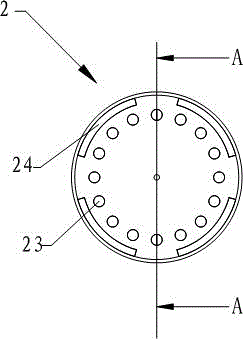

[0033] like Figure 2-4 As shown, the conical cap 2 includes a central conical body 21 and a surrounding flange 22 , and the conical cap 2 is installed in the inner cavity of the tubular body 1 through the interference fit between the flange 22 and the inner wall of the tubular body 1 . The extension direction of the flange 22 around the conical cap 2 is the same as that of the cone 21 , and the extension direction of the flange 22 faces the refrigerant inlet pipe 3 , that is, the tip of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com