Crack opening two-direction deformation monitoring structure and measurement method

A deformation monitoring and crack technology, applied in measuring devices, instruments, etc., can solve the problems of low accuracy, many restrictions, and it is difficult to reflect the bidirectional deformation law of cracks, and achieve the effect of convenient observation and simple structure combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

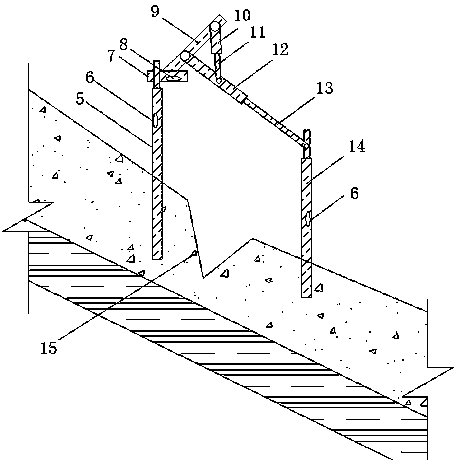

[0033]The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

[0034] The technical requirements for the burial of the vertical fixing rods, the technical requirements for the installation and construction of the vial, etc. will not be repeated in this embodiment, and the embodiments of the structure involved in the present invention will be focused on.

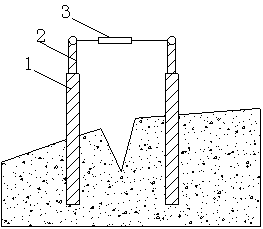

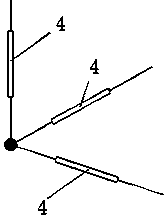

[0035] refer to image 3 , Figure 4 As shown, the crack opening two-way deformation monitoring structure includes an upper vertical fixed rod 5, a vertical level bubble 6, a horizontal cross bar 7, a horizontal level bubble 8, an oblique fixed rod 9, an angle measuring sensor 10, a distance measuring sensor 12 and Bottom vertical fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com