Vibration detection method of hoist main shaft based on psd laser triangulation method

A laser triangulation and vibration detection technology, which is used in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problem that the measurement conditions or the complexity of the equipment cannot meet the requirements of the vibration detection of the main shaft of the mining hoist.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

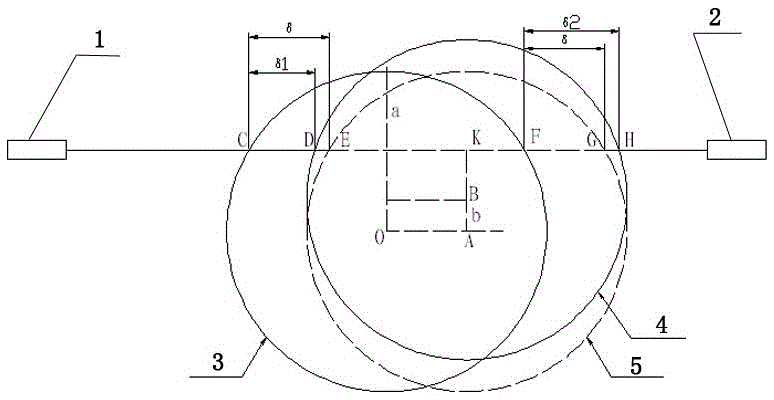

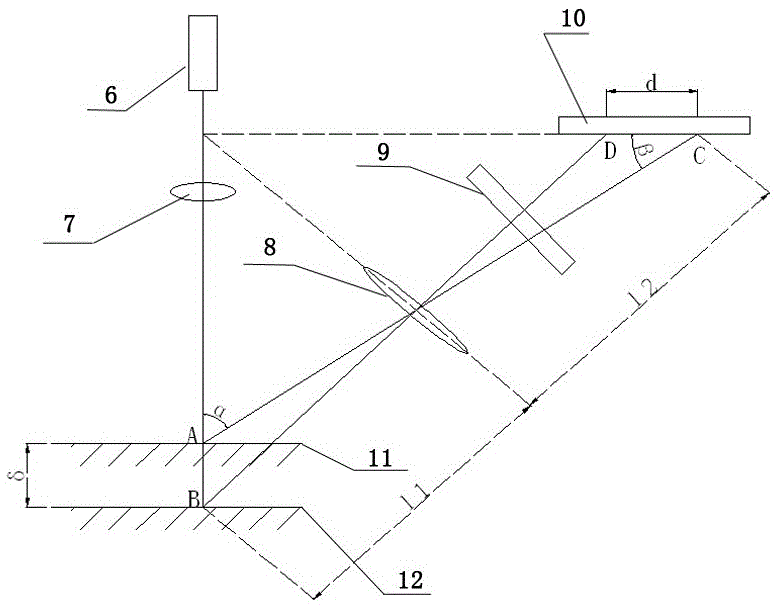

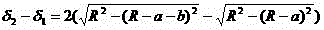

[0010] The invention is a vibration detection method for the main shaft of a mine hoist, which uses the characteristics of good monochromaticity, good directionality, and high brightness of the laser, and proposes a design scheme for an intelligent sensor with a vibration detection function for the main shaft of a mine hoist. The sensor combines the laser triangulation method and the position sensitive detector PSD to monitor the vibration displacement of the shaft of the mine hoist in the horizontal and vertical directions in real time and accurately.

[0011] like figure 1 and figure 2 As shown, the optical path system of a single sensor (the first sensor or the second sensor) is composed of a laser, a collimator lens, a receiving lens, an optical filter, a PSD position sensitive sensor (photosensitive element), and a signal processing circuit (the signal processing circuit is connected to On the PSD, the final output is the voltage. The distance that the light spot moves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com