Simulating system used for shield tunnel synchronous grouting test and test method thereof

A technology of synchronous grouting and simulation system, applied in the field of underground construction engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

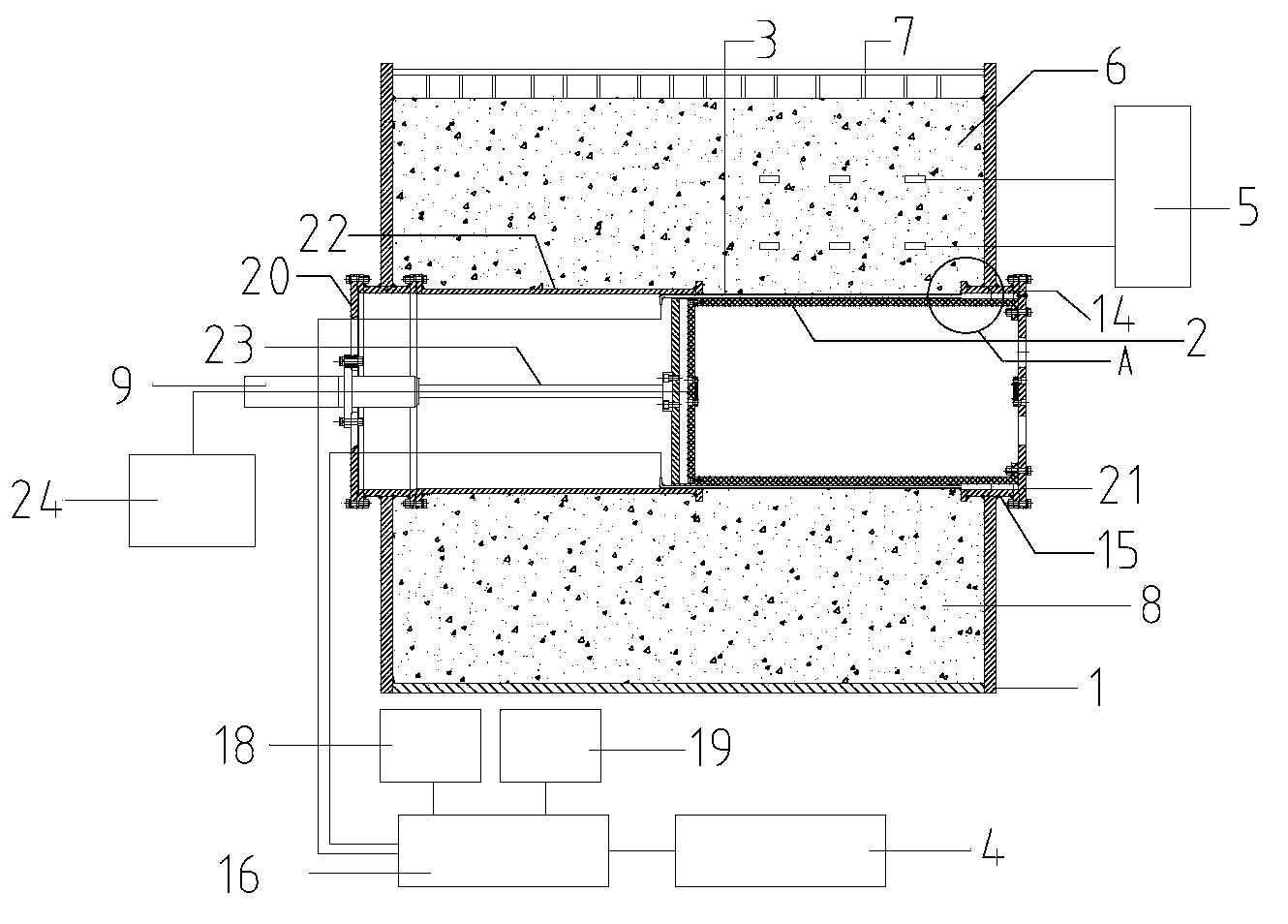

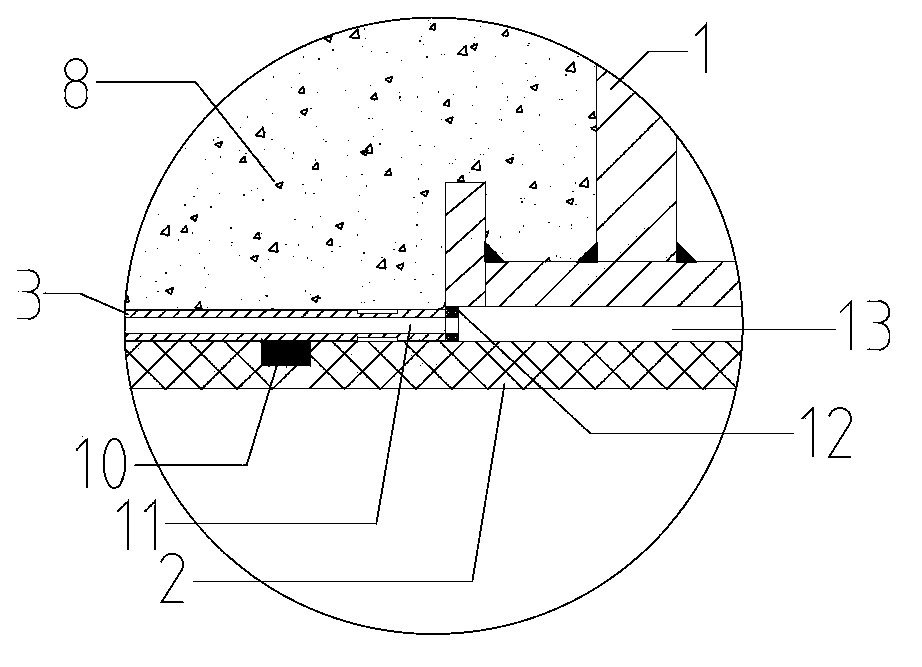

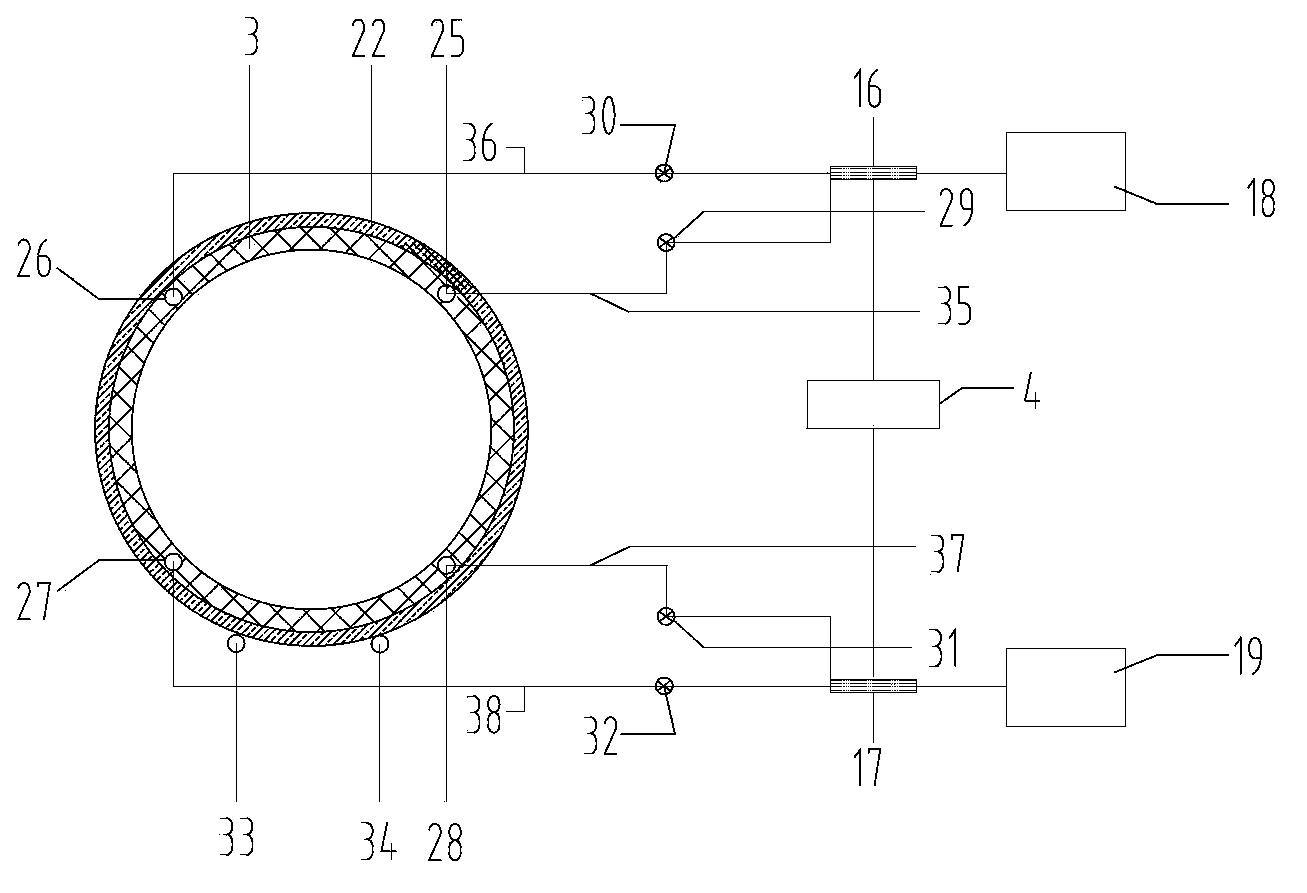

[0083] figure 1 It is a structural schematic diagram of the present invention. Wherein, the tube piece 2 is a transparent organic glass cylindrical member, and the right opening end is fixed to the right end cap 21 and arranged coaxially. The steel guide barrel 22 is a steel circular tubular member with openings at both ends, and its axis is horizontally arranged in the soil box 1. The bolts are fixed and welded to the opening of the left soil box. The opening end of the right side is tightly sleeved on the outside of the steel simulated shield shell 3, and the simulated shield shell 3 is tightly sleeved on the outside of the simulated segment 2. The simulated shield shell 3 The right end is overlapped with the upper connecting rod 14 of the right end cover and the lower connecting rod 15 of the right end cover, the right end of the simulated segment 2 is fixed with the bolts of the right end cover, and the upper connecting rod 14 of the right end cover and the lower connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com