Sampler for multi-channel gases and particulate matters and using method of sampler

A particle and multi-channel technology, applied in the direction of sampling devices, etc., can solve the problems of high transportation costs such as instrument purchase costs and manual sampling costs, and achieve the effects of saving purchase costs and operating energy, saving costs, reducing labor costs and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

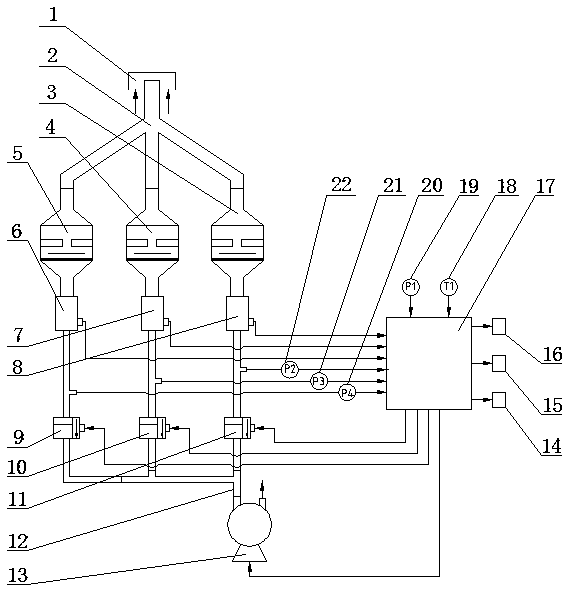

[0017] Embodiment one, such as figure 1 As shown, a multi-channel gas and particle sampler includes a sample gas inlet 1, a first multi-way tube 2, and three sampling heads: TSP cutter 3, PM10 cutter 4, PM2.5 cutter 5, The flow sensor includes a first flow sensor 6, a second flow sensor 7, a third flow sensor 8, a display screen 14, a keyboard 15, a USB interface 16, a single-chip microcomputer 17, and an ambient temperature sensor 18. The pressure sensor includes the first pressure sensor 20, the second flow sensor Two pressure sensors 21, a third pressure sensor 22, and an atmospheric pressure sensor 19; the sample gas inlet 1 is connected in parallel with the air inlets of the TSP cutter 3, the PM10 cutter 4, and the PM2.5 cutter 5 through the first multi-way pipe 2 The air outlet of sampling head is connected with flow sensor, pressure sensor, air extraction device, and described air extraction device comprises flow control valve, the air extraction pump 13 that is connect...

Embodiment 2

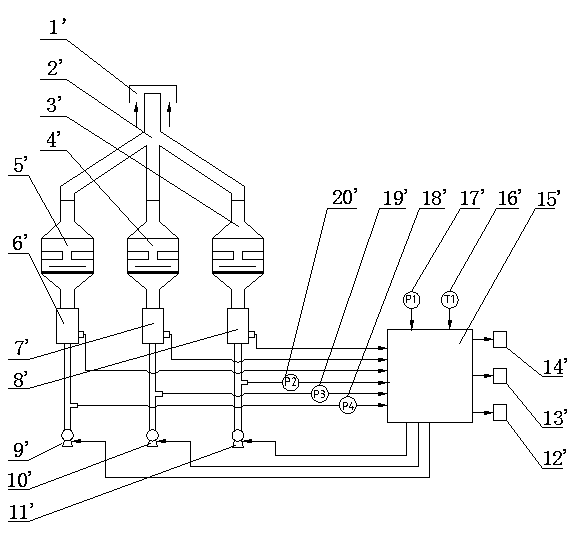

[0020] Embodiment 2, compared with Embodiment 1, the difference is that the air extraction device includes an air extraction pump, such as figure 2 As shown, a multi-channel gas and particle sampler includes a sample gas inlet 1', a first multi-way tube 2', and three sampling heads: TSP cutter 3', PM10 cutter 4', PM2.5 Cutter 5', the flow sensor includes a first flow sensor 6', a second flow sensor 7', a third flow sensor 8', a display screen 12', a keyboard 13', a USB interface 14', a microcontroller 15', and an ambient temperature sensor 16', the pressure sensor includes a first pressure sensor 18', a second pressure sensor 19', a third pressure sensor 20', and an atmospheric pressure sensor 17'; the sample gas inlet 1' is connected in parallel with the TSP The air inlet of cutter 3 ', PM10 cutter 4 ', PM2.5 cutter 5 '; The air pumps include a first air pump 9', a second air pump 10' and a third air pump 11'.

[0021] The air outlet of the TSP cutter 3' is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com