Preparation method of aunps-pdms composite microfilm biosensor

A biosensor and micro-film technology, applied in the field of biosensors, can solve the problems such as the structural processing complexity of the non-characteristic adsorption film capacitive sensor of the cantilever beam structure, and achieve the effects of high sensitivity, reasonable design and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

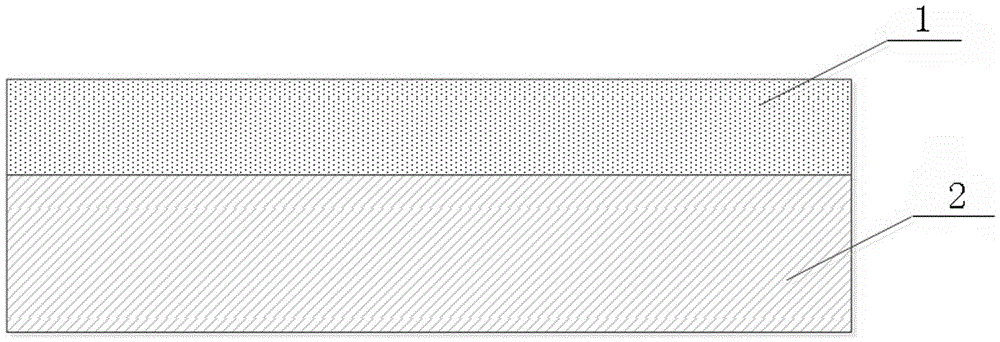

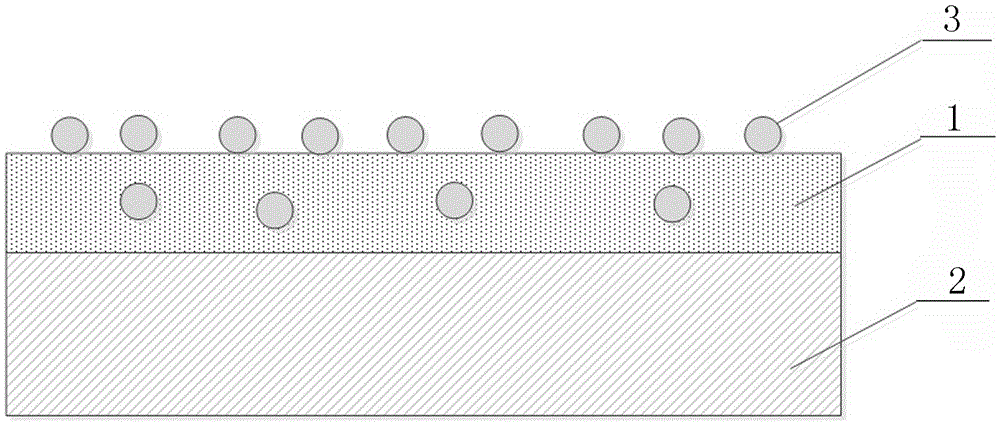

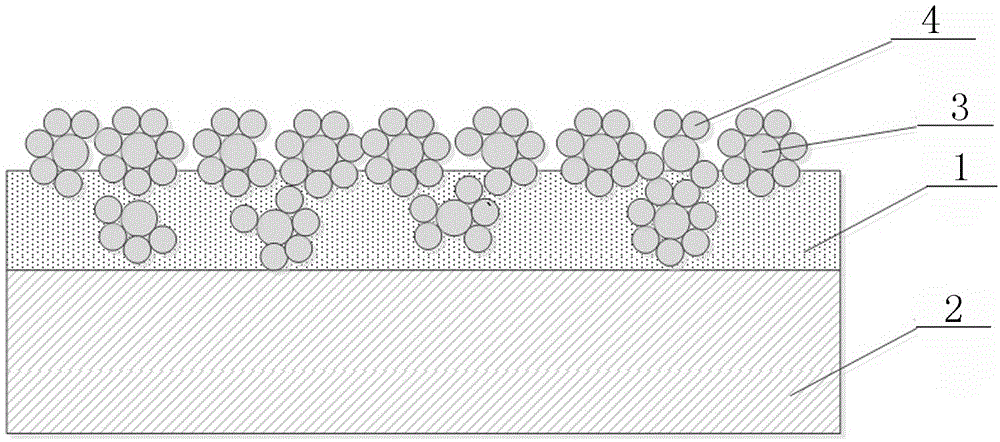

[0031] A method for preparing an AuNPs-PDMS composite microfilm surface stress biosensor, comprising the steps of:

[0032] (1) Clean the glass sheet 2, and use TMCS to silanize the glass sheet; the specific method is as follows:

[0033] Prepare a glass slide with a size of 1.3cm×1.3cm. Prepare the cleaning solution according to the volume ratio (concentrated sulfuric acid: hydrogen peroxide = 4: 1), and put the glass slide into it. Use a cleaning machine to wash at room temperature for 15 minutes. After cleaning, rinse the glass piece with deionized water and dry it with nitrogen. Prepare the silylating reagent TMCS, put the glass slide into a petri dish, drop a certain amount of silanizing reagent, cover the petri dish, rinse with deionized water after 20 minutes, and blow dry with nitrogen. At this point, the silanization of the glass s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com