Magnetic latching relay of directly-operated type magnetic circuit structure

A magnetic latching relay, direct-acting technology, applied in electromagnetic relays, relays, detailed information of electromagnetic relays, etc., can solve the problems of increasing product volume, system volume, and cost, and achieve small product volume and product volume. The effect of change and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

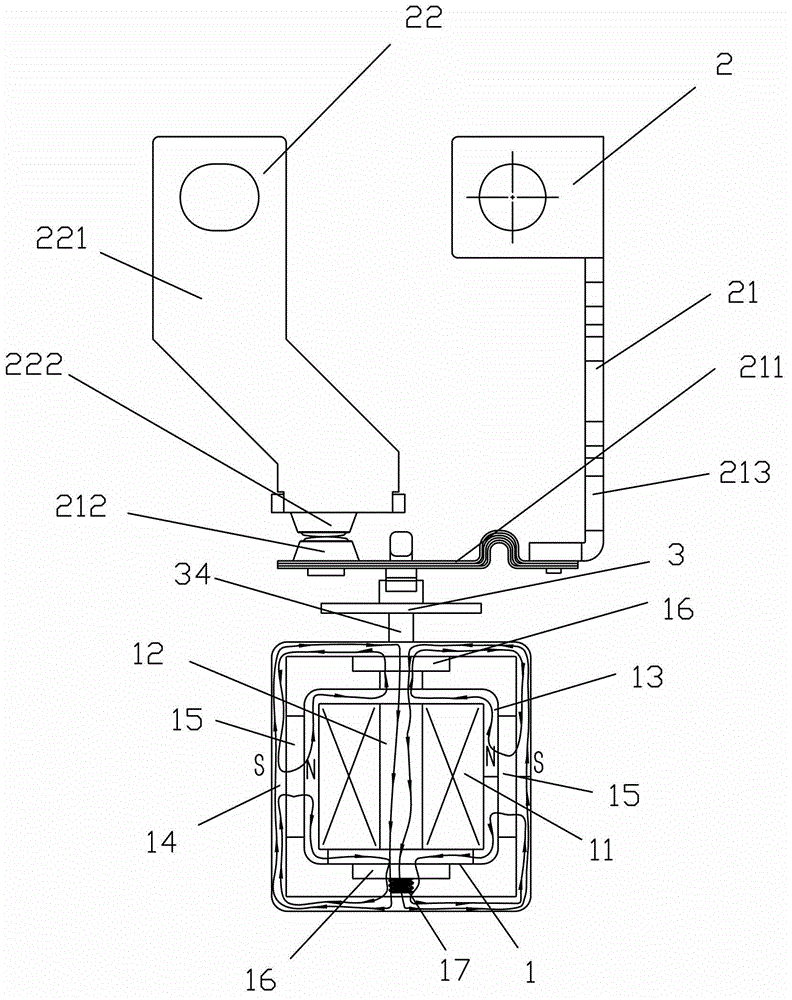

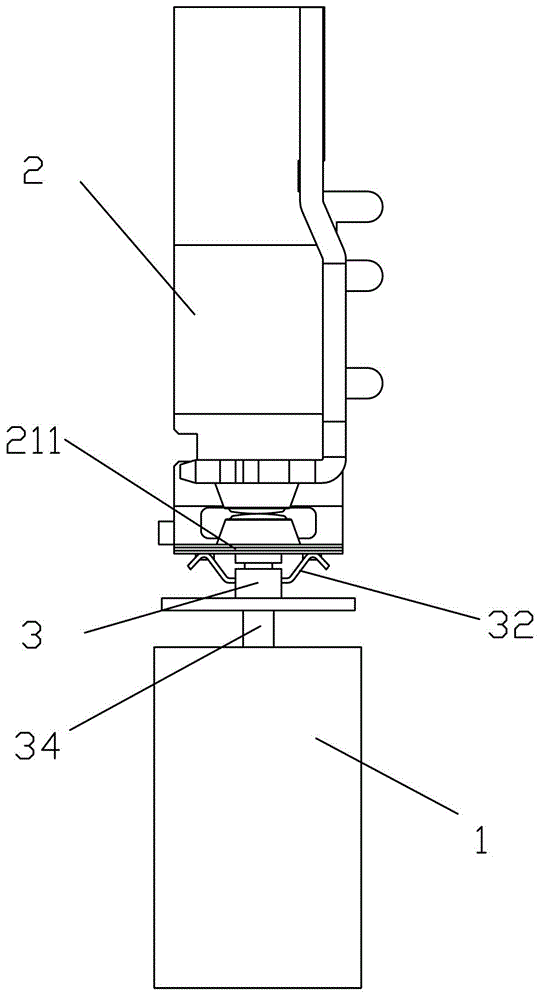

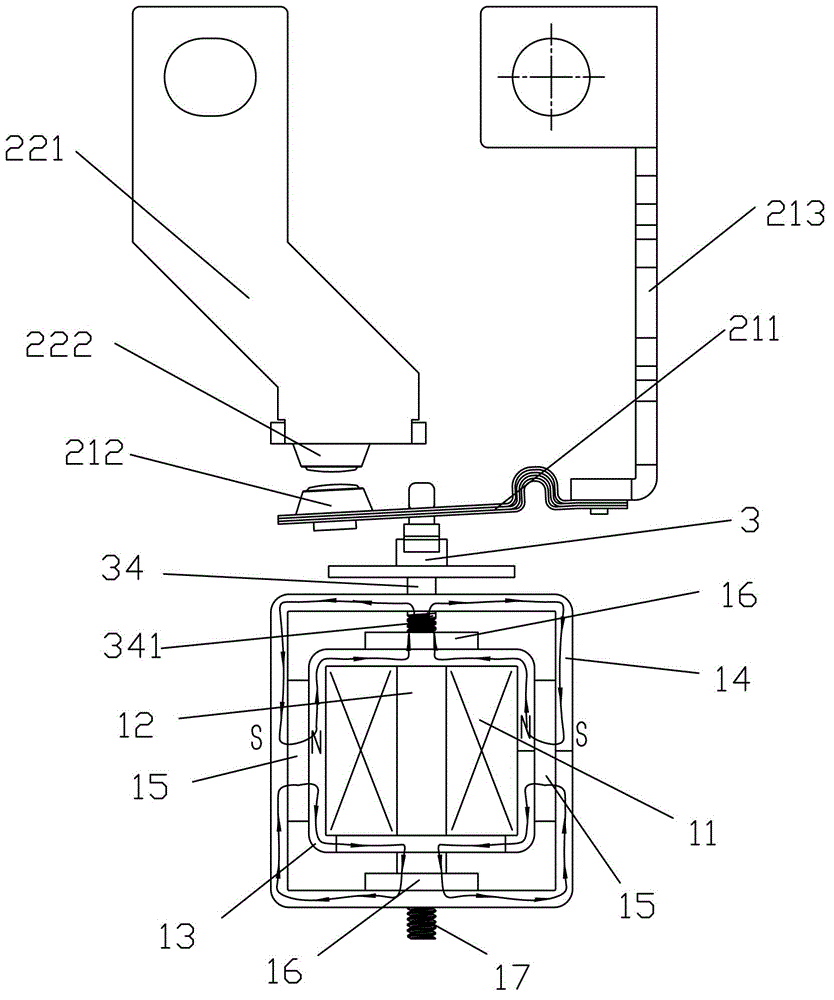

[0030] Embodiment one, see Figure 1 to Figure 7 As shown, the magnetic latching relay of the direct acting magnetic circuit structure of the present invention includes a magnetic circuit part 1, a contact part 2 and a push part 3; the push part 3 is connected between the magnetic circuit part 1 and the contact part 2; the contact part 2 Comprising a moving spring part 21 and a static spring part 22, the moving spring part 21 includes a moving reed 211 and a moving contact 212, and the static spring part 22 includes a static spring 221 and a static contact 222, and the moving spring 211 and the static spring 221 are respectively mounted on Corresponding positions, so that the movable contact 212 and the static contact 222 are adapted; the magnetic circuit part 1 includes a coil 11, an iron core 12, an inner yoke 13, an outer yoke 14, two permanent magnets 15 and two magnetic poles sheet 16; the inner yoke 13 and the outer yoke 14 are mouth-shaped structures respectively; the i...

Embodiment 2

[0047] Embodiment two, see Figure 8 As shown, the magnetic latching relay of the direct-acting magnetic circuit structure of the present invention is different from the first embodiment in that the magnetic latching relay has a left and right two-way structure, so the contact part includes two sets of moving spring parts 21 and static spring parts. Part 22 : fix the two ends of the iron core of the magnetic circuit part 1 with a corresponding piece of magnetic pole piece respectively through the threads of the connecting rods of the two sets of pushing parts 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com