Brush carrier for electromotor, manufacturing method of brush carrier, and electromotor

A brush holder and motor technology, applied in brush manufacturing, electric components, circuits, etc., can solve the problems of loss of shape stability, limiting the accuracy of positioning carbon brushes, etc., to achieve the effect of saving devices and improving functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

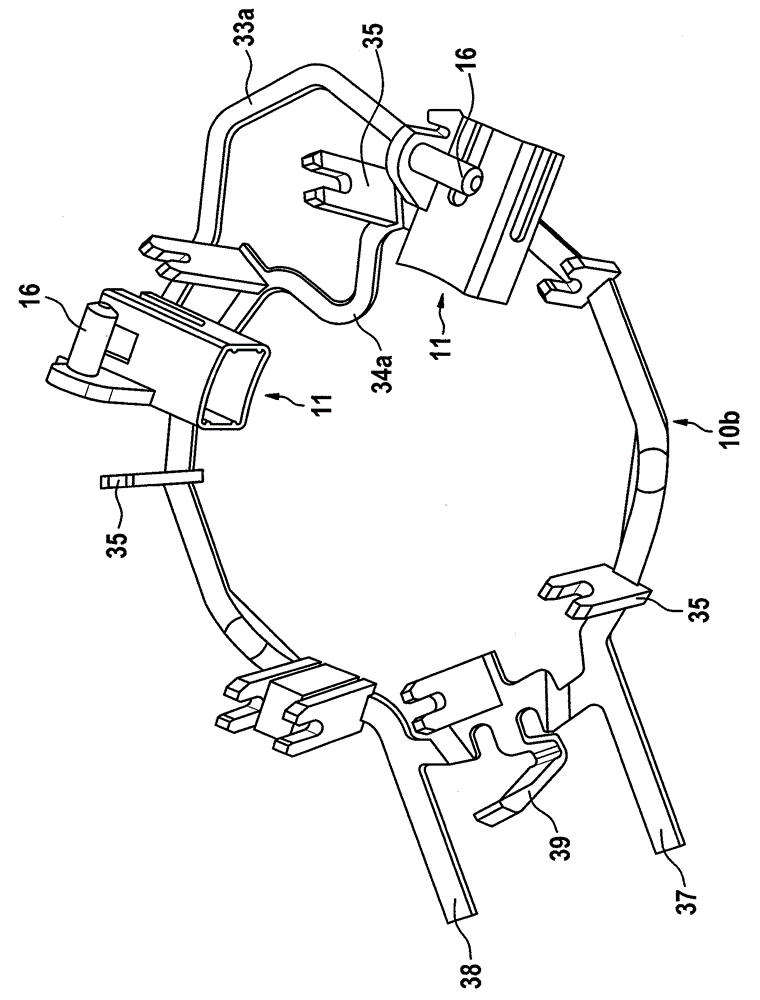

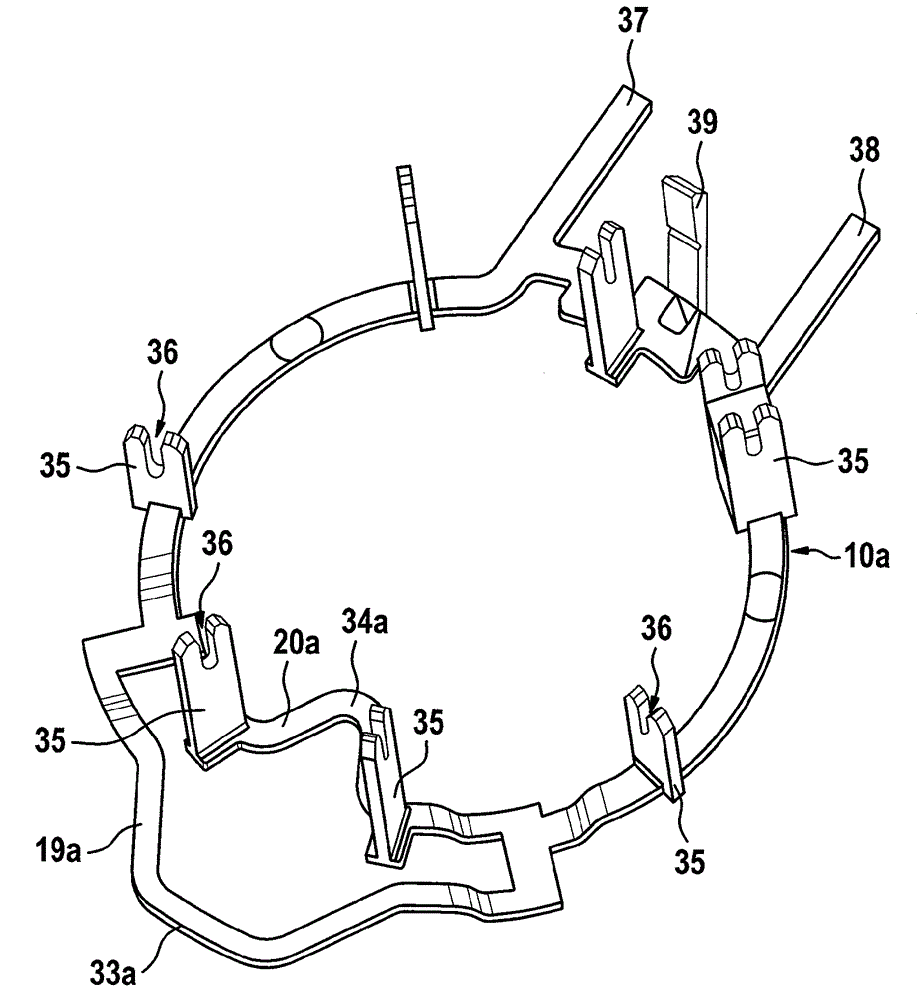

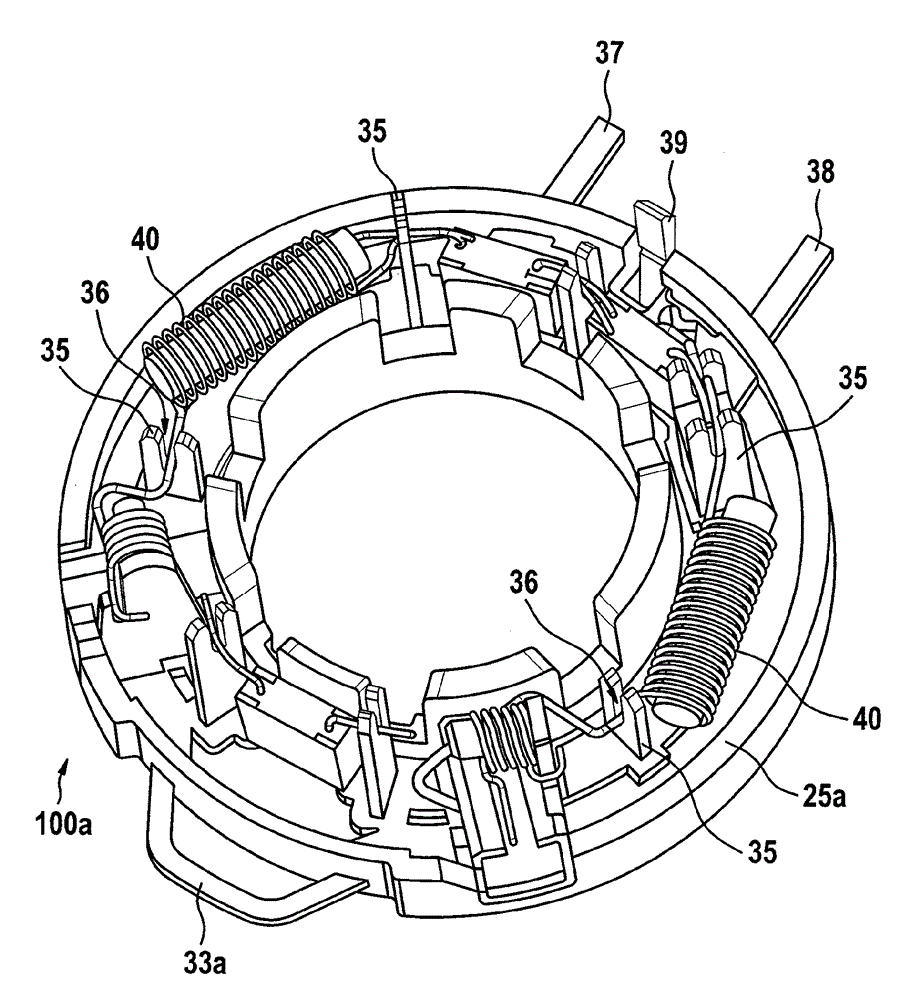

[0026] in the attached figure 1 Shown in the insert 10, which acts as figure 2 Components of the brush holder 100 shown in . The brush holder 100 is in turn part of an electric motor which is used for adjusting elements (windows, seats or similar institutions).

[0027] In the exemplary embodiment shown, the insert 10 comprises two receiving elements 11 , 12 in the form of a charcoal burner for charcoal brushes (not shown). The receiving elements 11 , 12 each have, by way of example and without limitation, a rectangular cross-section with a continuous longitudinal opening 13 , wherein at the upper side and at the sides of each receiving element 11 , 12 Longitudinal gaps 14 , 15 are formed over partial regions of the length of the receiving elements 11 , 12 . At the one receiving element 11 , a fastening element 16 for a spring element not shown is integrally formed on its upper side, which acts on the carbon brushes with a spring force in a known manner, so that The spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com