A buck high-frequency isolated five-level inverter

A high-frequency isolation, five-level technology, used in electrical components, AC power input to DC power output, output power conversion devices, etc. problem, to achieve the effect of good voltage spectrum characteristics, miniaturization and widening of the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

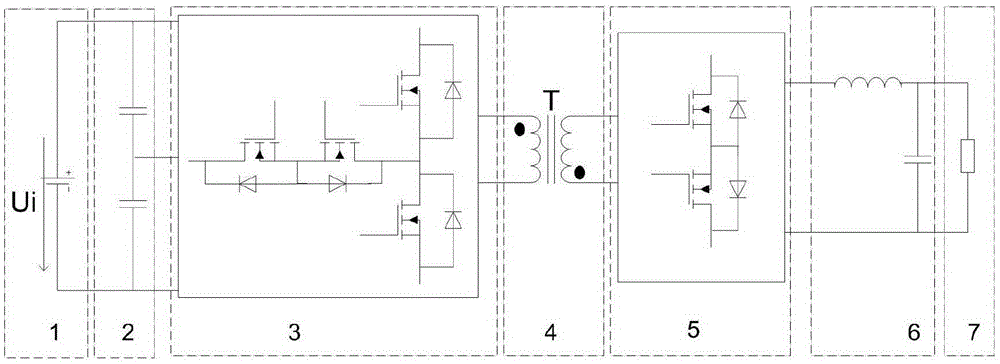

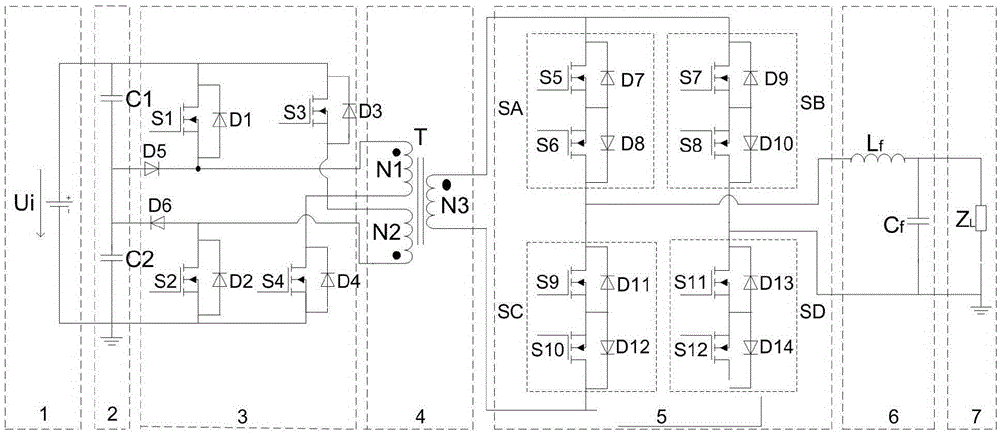

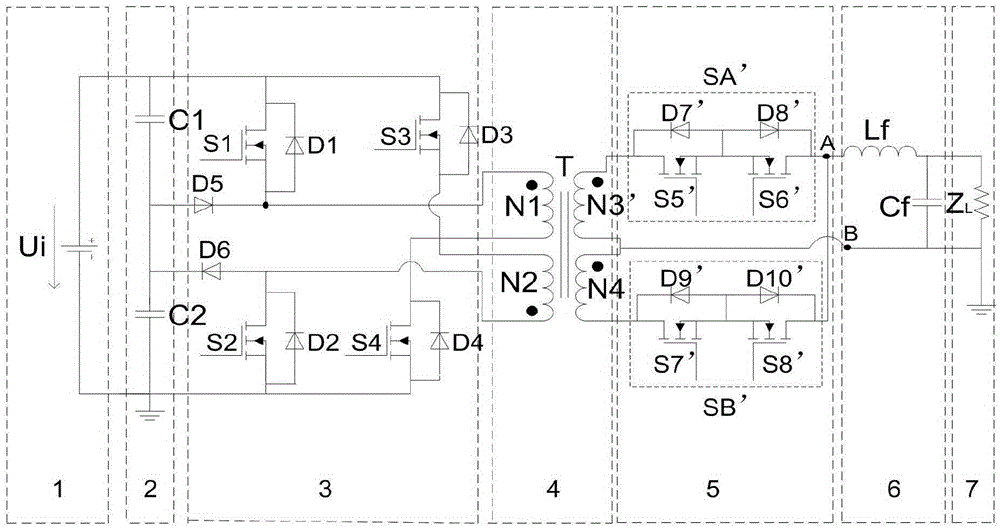

[0022] Such as figure 1 As shown, according to a preferred embodiment of the present invention, a Buck high-frequency isolated five-level inverter is composed of an input DC power supply unit 1, a voltage dividing capacitor 2, and a Buck high-frequency isolated five-level converter connected in sequence Unit 3, high-frequency isolation transformer 4, cycloconverter 5, output filter 6 and output AC load 7; wherein, the input DC power supply unit 1 includes an input DC power supply Ui, one end of the input DC power supply Ui and the voltage dividing capacitor 2 connection, the other end of the voltage dividing capacitor 2 is connected to one end of the Buck high-frequency isolated five-level conversion unit 3, the other end of the Buck high-frequency isolated five-level conversion unit 3 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com