Profiling bionic press roller

A technology of pressure rollers and bionic shrapnel, which is applied in the field of agricultural machinery, can solve the problems of reducing the degree of adhesion between soil and pressure rollers, increasing the pressure of pressure rollers on soil, and uneven soil compactness, so as to prevent slipping, good effect, and good solidity. The effect of soil action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

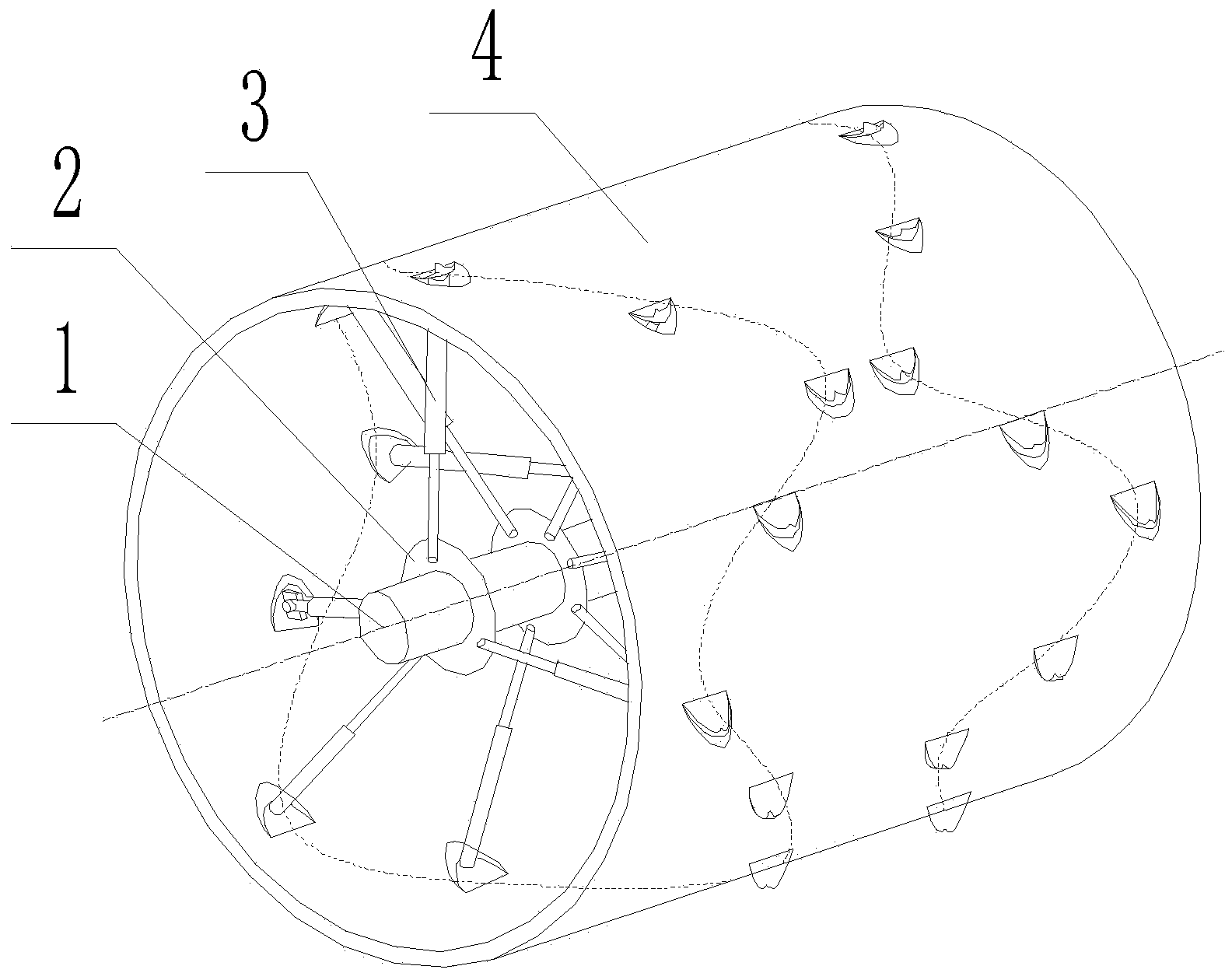

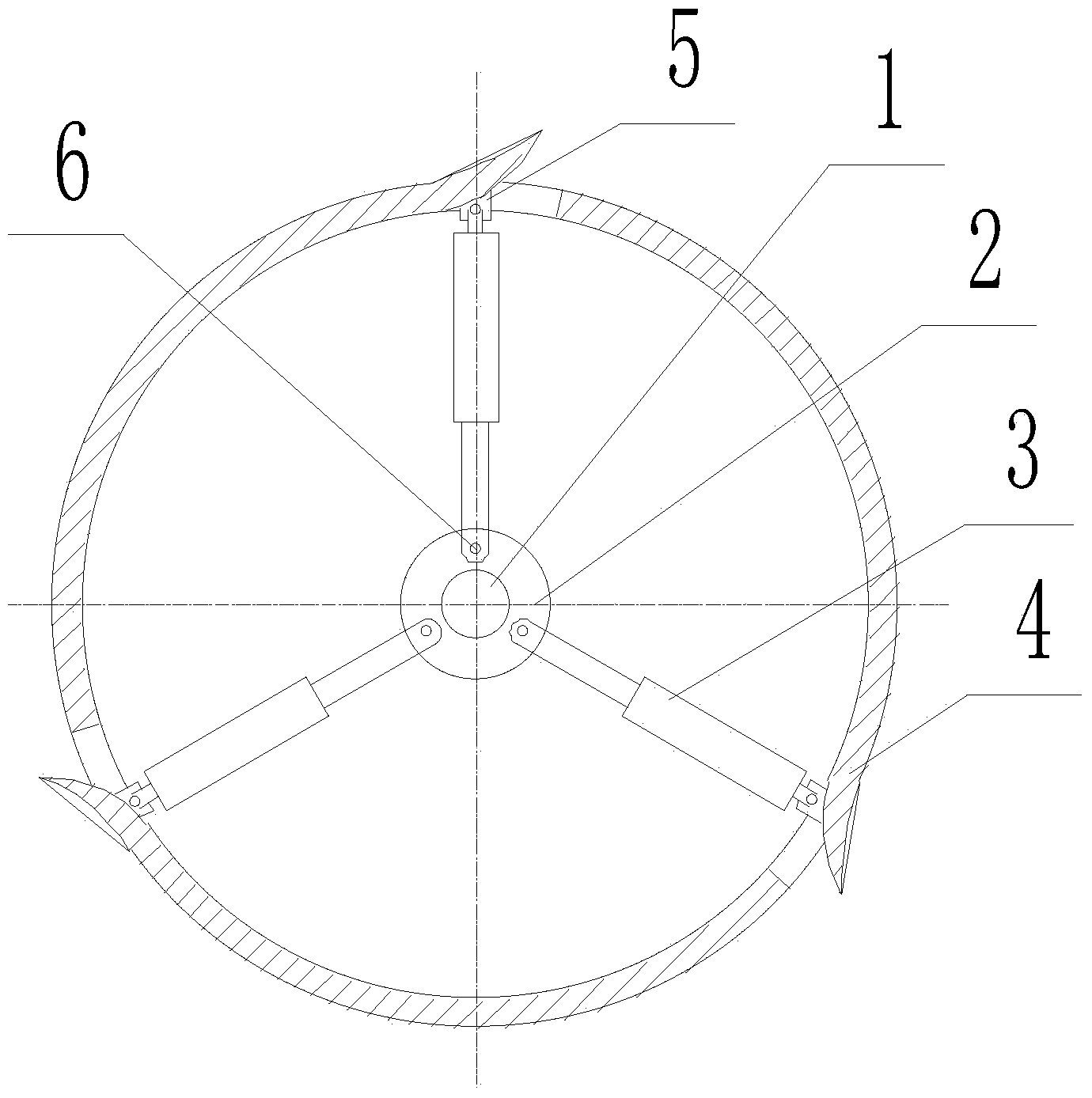

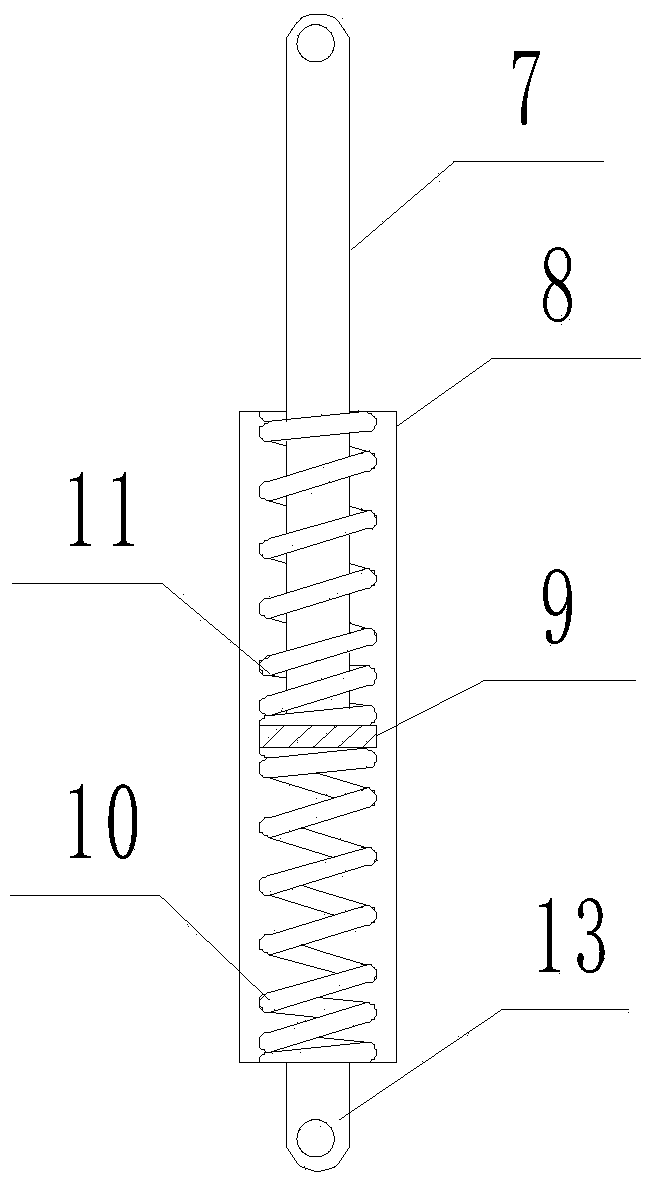

[0022] refer to figure 1 and figure 2 According to the present invention, a profiling bionic pressure roller includes a central shaft 1, a pressure roller cylinder 4 and n elastic spokes 3 with the same structure.

[0023] The surface of the pressure roller 4 has a bionic shrapnel 12 that can increase the contact force between the pressure roller and the soil, and can play a role in fixing the soil. The bionic shrapnel 12 are arranged on the surface of the pressure roller 4 according to a trigonometric function curve. The equation is:

[0024] y=Asin(6πx / D)+B

[0025] Among them: x represents the circumferential direction of the roller, y represents the normal direction of the roller surface; A and B are constants, and the value range of A is 50-100mm; the value range of B is 100-200mm; D is the diameter of the pressure roller .

[0026] And the two trigonometric functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com