Anti-displacement coil spring-type spine stabilization device

A technology for stabilizing the spine and spine, applied in the field of spine stabilization equipment, can solve problems such as inability to effectively support the spine, difficulty in processing, difficulty in manufacturing and processing the rod-shaped implant component 1, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

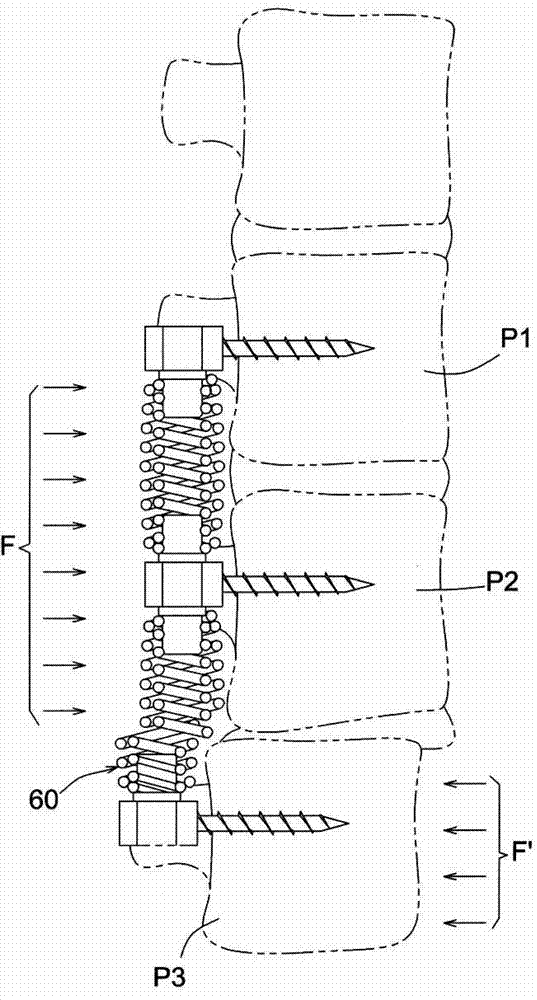

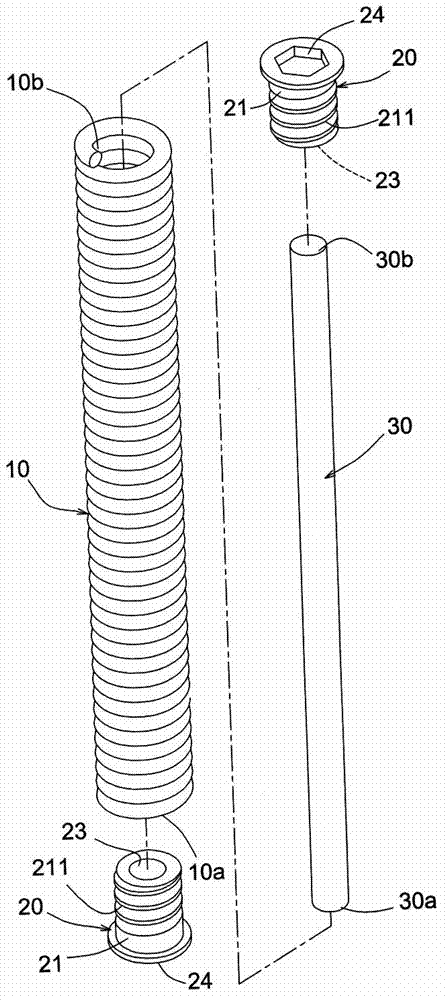

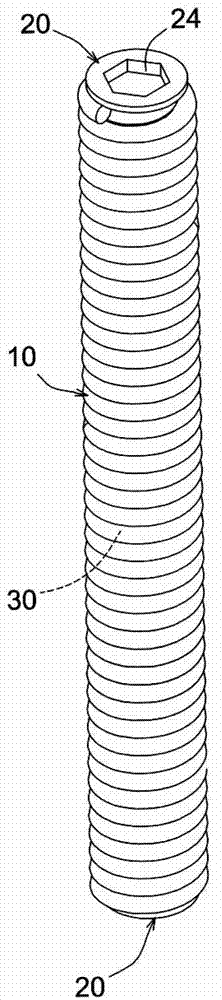

[0055] see Figure 2 to Figure 7 As shown, the present invention relates to a spring wire type spinal stabilization device with anti-deviation, which can be fastened by several pedicle screws 40, and each of the pedicle screws 40 is fixed on one side of the spine 50, The spine stabilization device includes a spring rod member 10, and an engaging member 20 is fastened at both ends thereof, and an elastic rod 30 is inserted between the two engaging members 20, so that the elastic rod 30 is inserted axially. In the spring bar member 10 .

[0056] The anti-deviation spring wire type spine stabilization device disclosed in the present invention includes: a spring rod member 10, which is a longitudinally long spring rod composed of several continuous spring coils wound by a spring wire in a helical shape; two connecting members 20 Each connecting member 20 includes a connecting section 21 to be fixedly connected to the two ends 10a, 10b of the spring bar member 10, and on the oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com