Triethylene glycol furnace exhaust recycling system and method for producing slices

An exhaust gas recovery and triethylene glycol technology, applied in separation methods, chemical instruments and methods, vapor condensation, etc., can solve problems such as unfavorable health of operators, pollution of surrounding air, and high irritation, so as to ensure physical health, The effect of reducing pollution and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

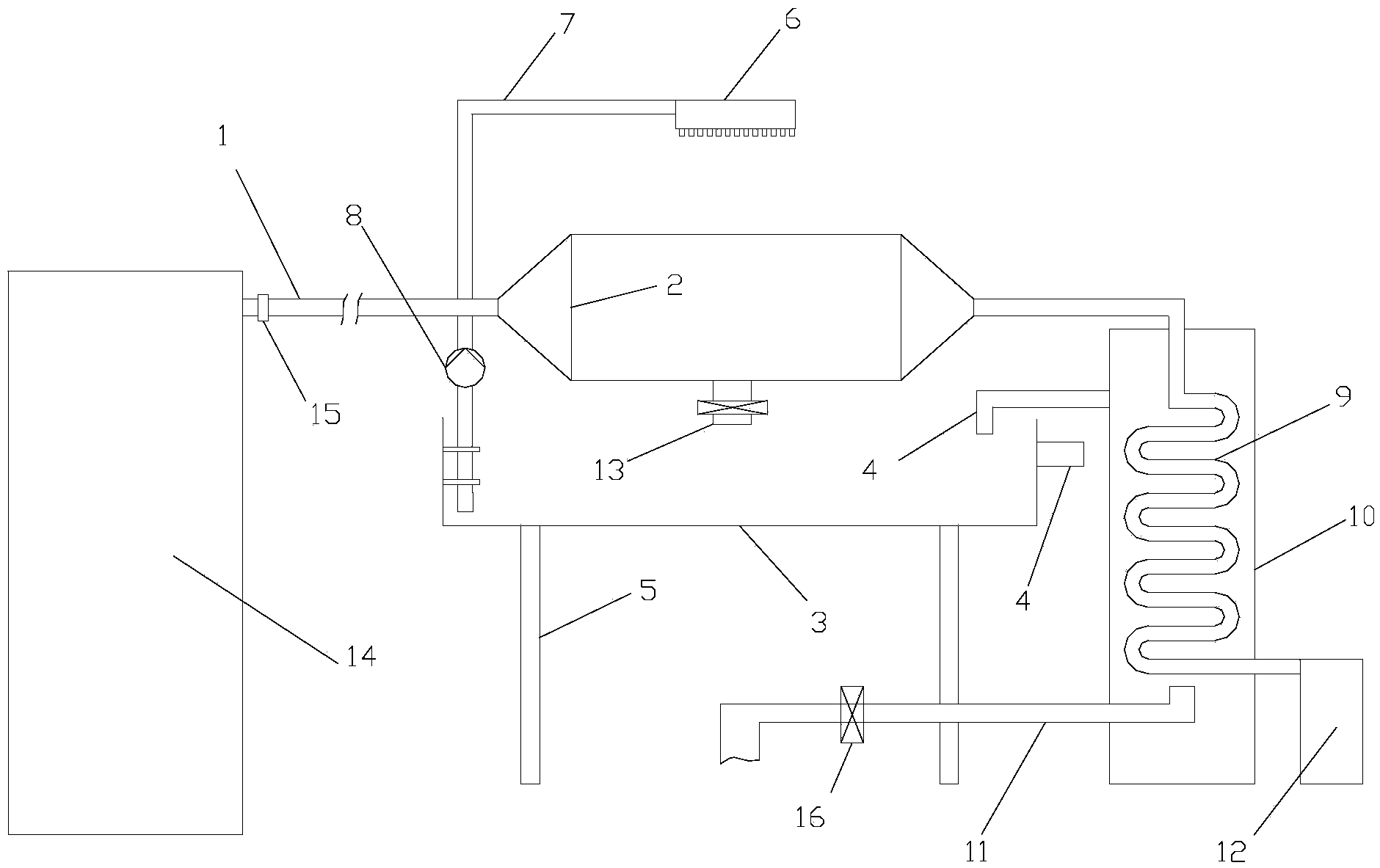

[0012] Such as figure 1 As shown, the triethylene glycol furnace exhaust gas recovery system for slice production described in this embodiment includes a triethylene glycol furnace 14, and the exhaust port 15 of the triethylene glycol furnace 14 is connected with an outlet pipe 1, and also includes A cooling chamber 2 with tapered ends, the bottom of the cooling chamber 2 is provided with a condensate outlet 13, a water collection tank 3 is provided below the cooling chamber 2, an overflow pipe 4 is arranged on the water collection tank 3, and the bottom of the water collection tank 3 A bracket 5 is provided, and a spraying device 6 is provided above the cooling chamber 2, and the spraying device 6 is connected with a suction pipe 7 that goes deep into the sump 3. During the spraying process of the spraying device 6 from above to the water, Part of the heat of the water can be dissipated to reduce the temperature of the spray water, and a water pump 8 is provided on the suctio...

Embodiment 2

[0016] This embodiment discloses a method for recovering exhaust gas from a triethylene glycol furnace produced by slicing. The method adopts the exhaust gas recovery system of a triethylene glycol furnace described in Example 1, and is characterized in that: triethylene glycol gas is condensed in the cooling chamber to form Liquid triethylene glycol, the non-condensed triethylene glycol gas in the cooling chamber continues to enter the cooling coil for cooling, the cooling coil is located in the water tank, the temperature of the cooling coil is controlled by continuously injecting cooling water into the water tank, so that It achieves a stable cooling effect, and finally the cooled liquid triethylene glycol flows into the condensation tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com