Laser processing head and processing method for automatically controlling processing focal length

A laser processing head and laser processing technology, used in manufacturing tools, laser welding equipment, metal processing equipment, etc., can solve the problems of time-consuming and laborious, inability to adapt to multiple varieties, multiple batches, automated production occasions, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

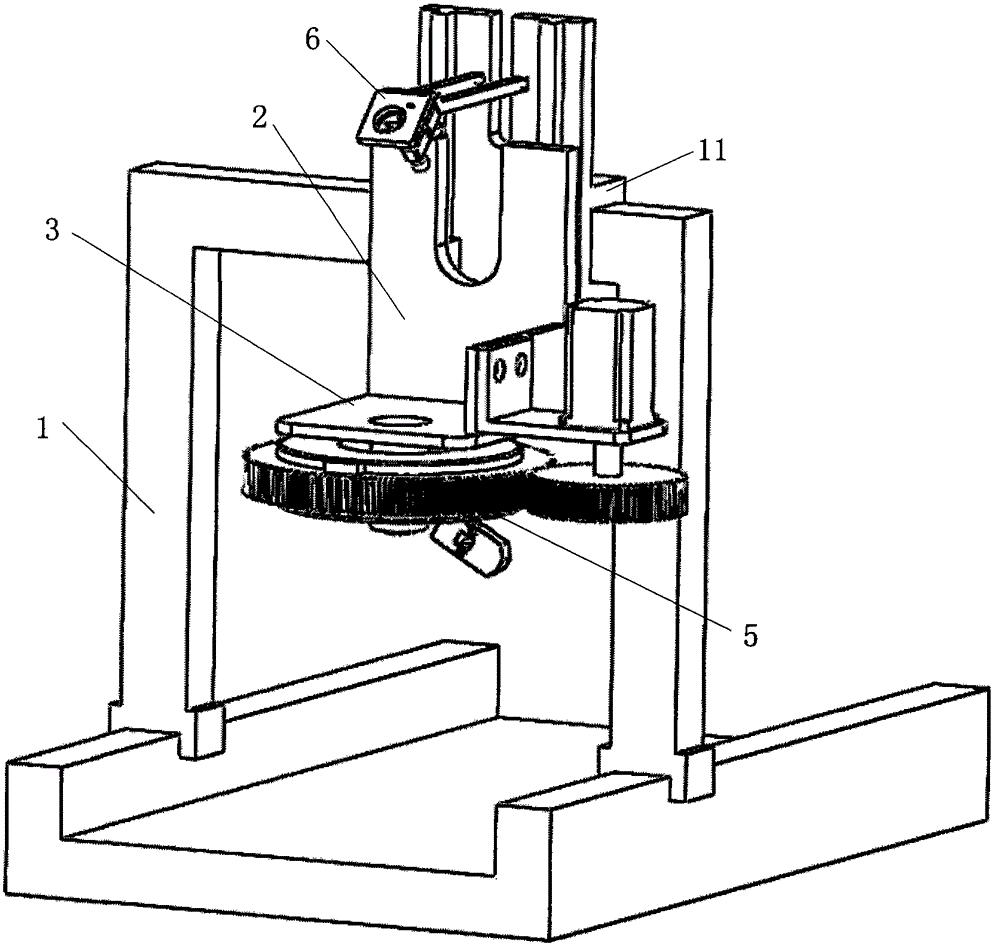

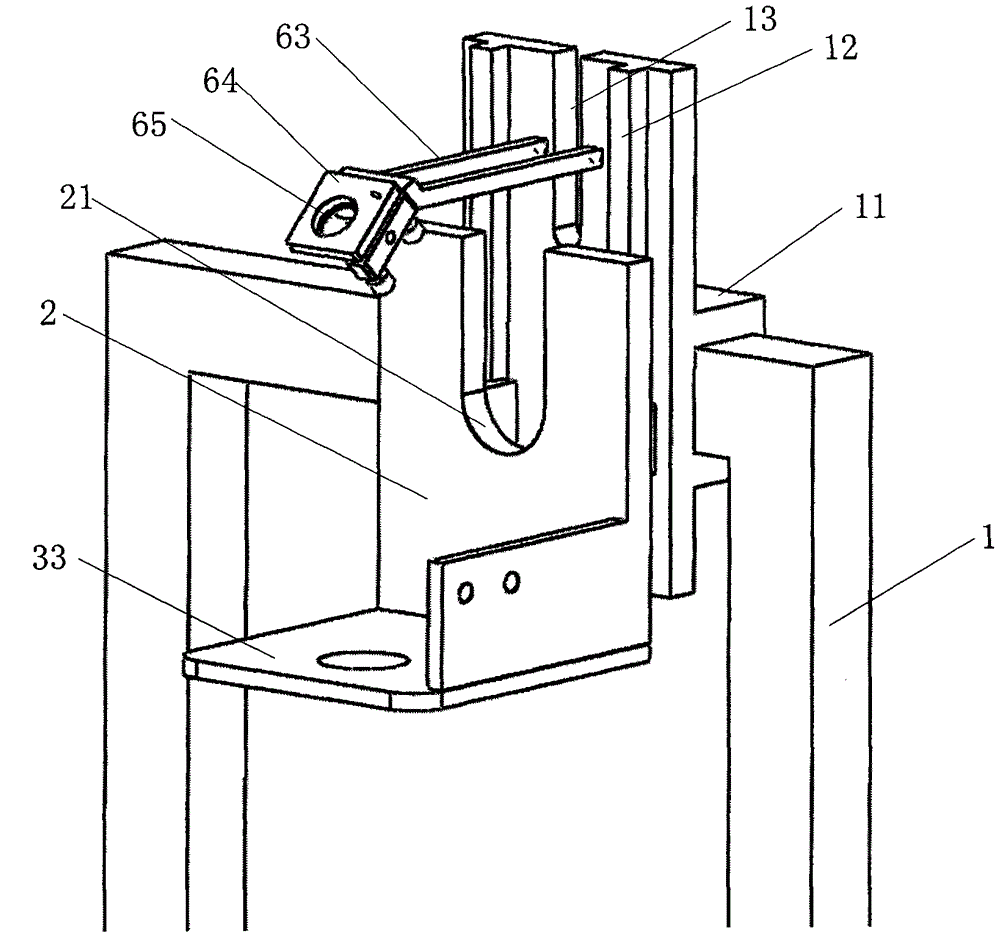

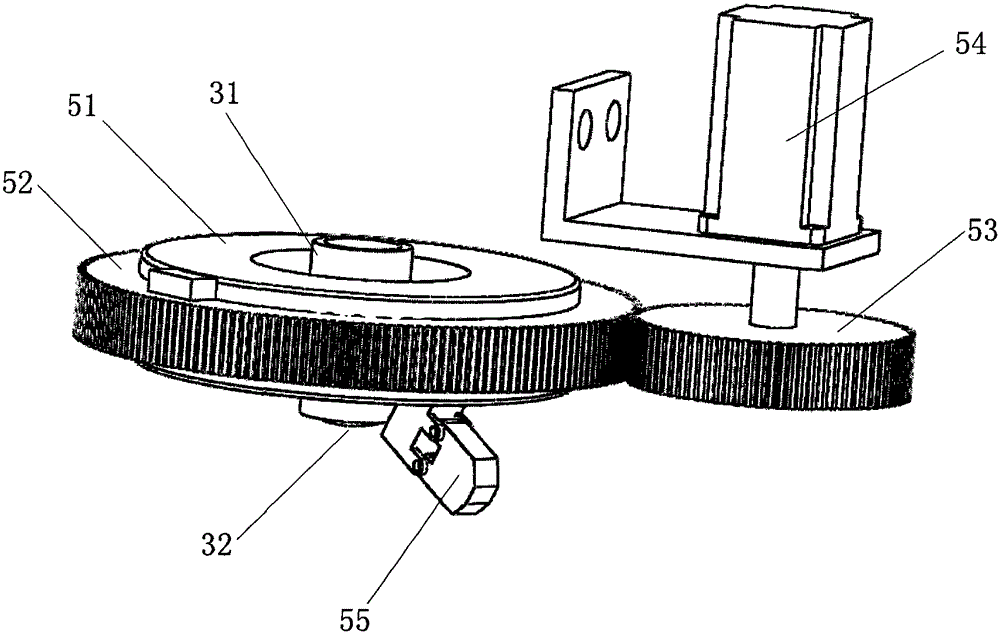

[0034] Such as Figure 1-3 As shown, the present invention provides a laser processing head that automatically controls the processing focal length, including a Z-axis lifting slide 2 , a light guide focusing mechanism 3 and a rotating distance measuring mechanism 5 .

[0035] The laser processing head needs to be installed on the laser processing machine tool. This embodiment only uses the XY two-axis motion support 1 with a simple structure as the laser processing machine tool for illustration, but the laser processing head can also be used for other laser processing machine tools. of.

[0036] Wherein, a horizontal slide plate 11 with two degrees of freedom of movement of X and Y is installed on the XY two-axis motion support 1; A light guide gap 13 for the laser beam to pass through; a lens mount 6 is installed above the light g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com