Machining method of wheel groove semi-finish milling cutter

A processing method and semi-finishing milling technology, which are applied in the processing field of semi-finishing milling cutters for wheel groove milling cutters, can solve problems such as the inability to guarantee machining accuracy and machining efficiency, achieve optimal cutting allowance distribution and machining parameters, improve service life, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

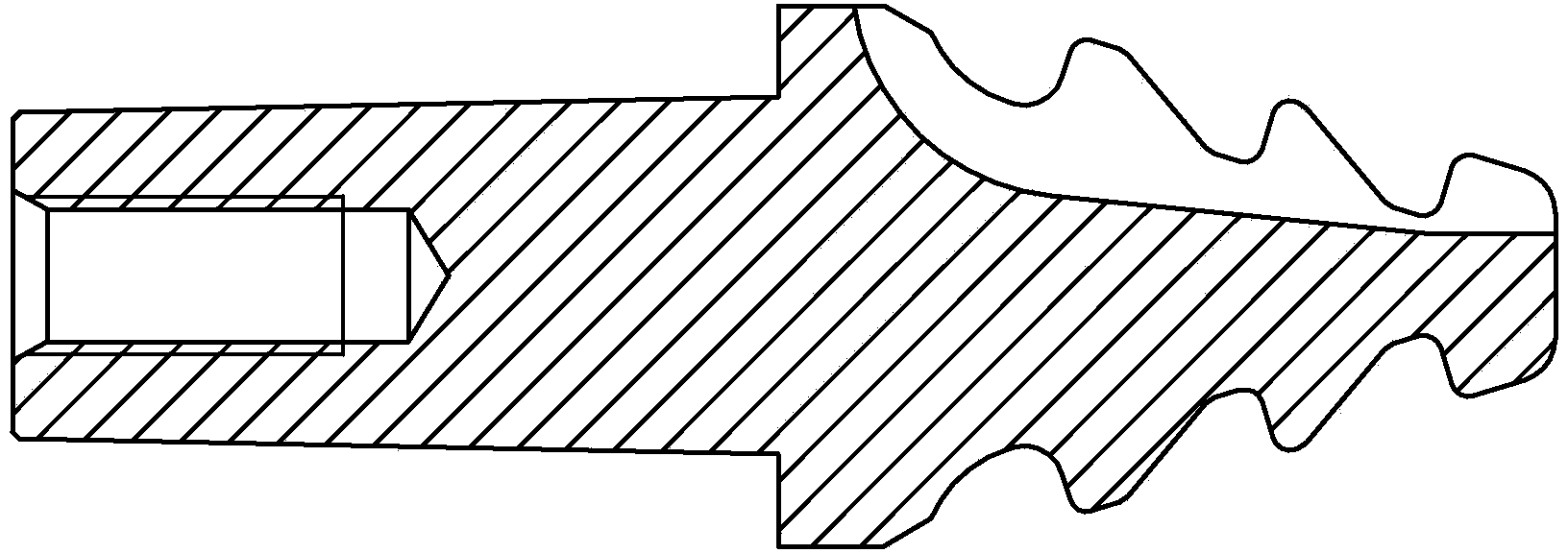

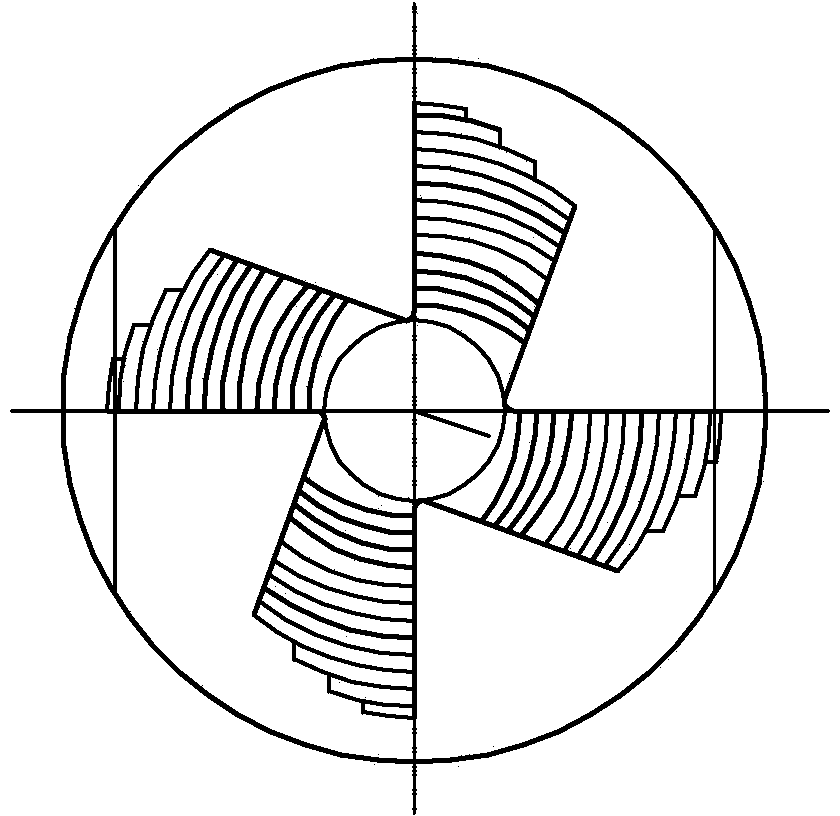

[0029] Specific implementation mode one: combine Figure 1-Figure 5 Describe the present embodiment, the wheel groove semi-finishing milling cutter machining method of the present embodiment is realized according to the following steps:

[0030] Step 1. Turning each part of the semi-finishing milling cutter on the ordinary lathe: Brown Sharp No. 9 taper 0.6 ~ 0.7mm, 16°48′ tapered single side 1.5mm, leave Φ10×10 auxiliary head at the right end, and hit the center Hole d=2mm, 0.5″ thread turning at the left end, hole chamfering 60°, turning parameters: speed 400r / min, feed rate 0.3mm / r, turning depth 1.5mm;

[0031] Step 2. Turning the wheel groove semi-finishing milling cutter profiles on the CNC lathe: each profile line is 0.4mm along the normal direction; wherein, the turning parameters are: speed 500r / min, feed rate 0.2mm / r, turning Depth 0.5mm;

[0032] Step 3. Milling wheel slot semi-finishing cutter tooth alignment on CNC milling machine: Turning parameters are: speed ...

specific Embodiment approach 2

[0043] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the heat treatment process in step 6 is: first preheat for 2 hours, the preheating temperature is 550 ° C, then put it in a medium temperature furnace to heat for 30 minutes at 850 ° C, and then put it at a high temperature Heat in the furnace at 1200°C for 15 minutes, then put it in the isothermal furnace at 600°C for 30 minutes, and finally put it in the tempering furnace at 550°C for 3 times, 2 hours each time. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com