A special fixture for testing the surface roughness of steering knuckle

A special fixture and steering knuckle technology, which is applied in the field of student school supplies, can solve the problems of limited roughness comparison sample size, unquantifiable data, and failure to meet the use requirements, etc., to achieve the effect of eliminating quality hidden dangers and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to have a deeper understanding of the present invention, a specific embodiment is listed below, and the present invention is further described in detail in conjunction with the accompanying drawings.

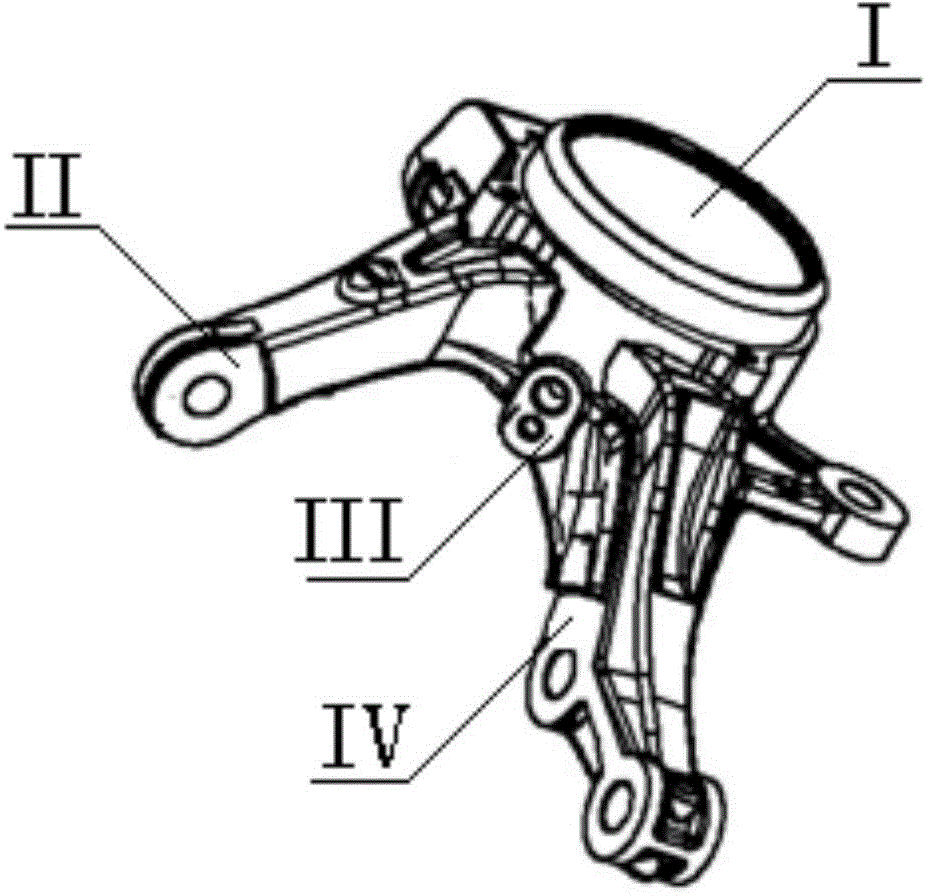

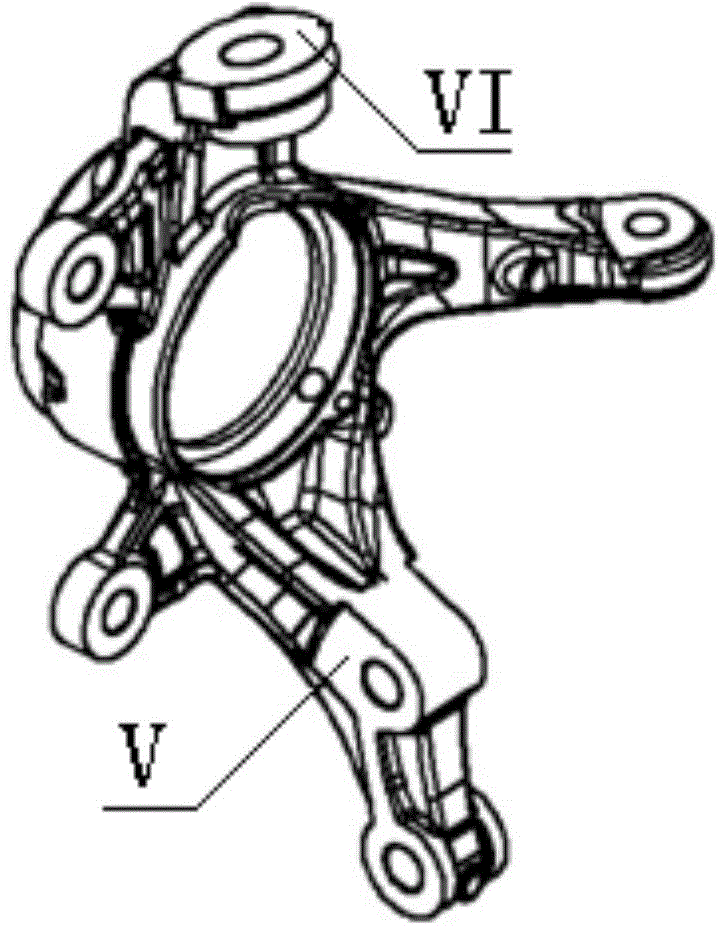

[0047] This embodiment is a special fixture used for the roughness detection of the steering knuckle. In this embodiment, the roughness detection of the six processing surfaces of the steering knuckle is required, such as figure 1 with figure 2 As shown, the processing surfaces to be tested are: bearing mounting hole I, joint arm surface II, ABS mounting surface III, first shock absorber support surface IV, second shock absorber support surface V and lower ball pin surface VI.

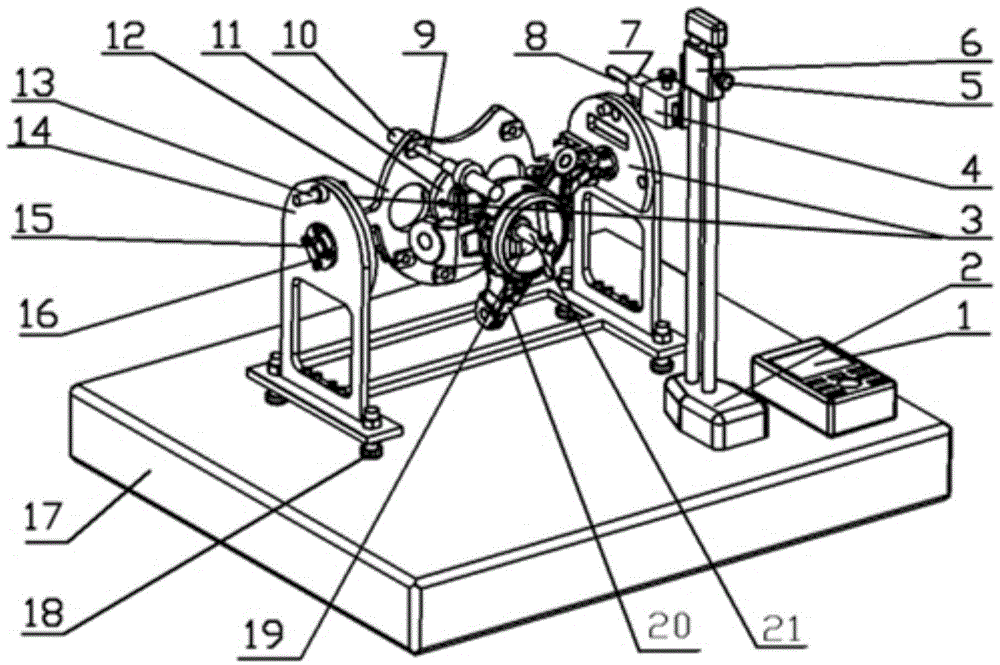

[0048] The special fixture described in this embodiment includes: side turntable 3, steering knuckle rotation limit pin 9, guide positioning sleeve 10, mandrel 11, center turntable 12, positioning pin 13, vertical plate 14, bearing end cover 15, bearing 16 , adjusting screw 18, pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com