a textile trolley

A cart and wheel technology, which is applied in the field of textile transport vehicles, can solve the problems of fewer storage brackets and fewer rolls, so as to improve work efficiency, increase the number of rolls that can be stored, and increase the number of rolls to be transported Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

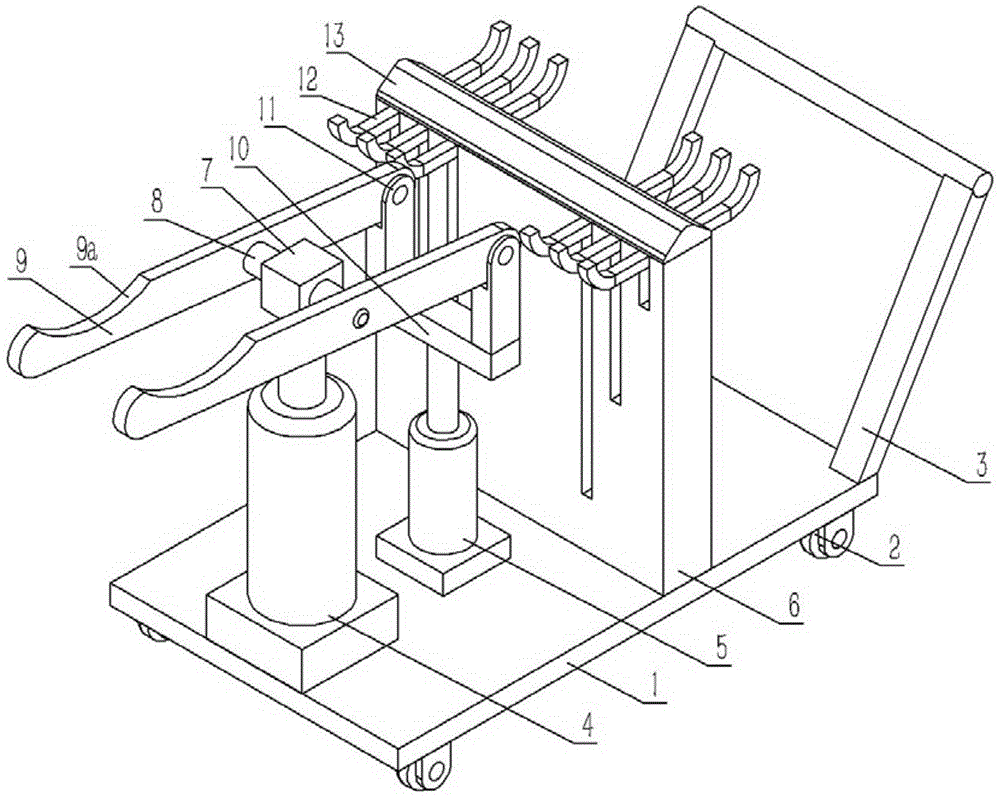

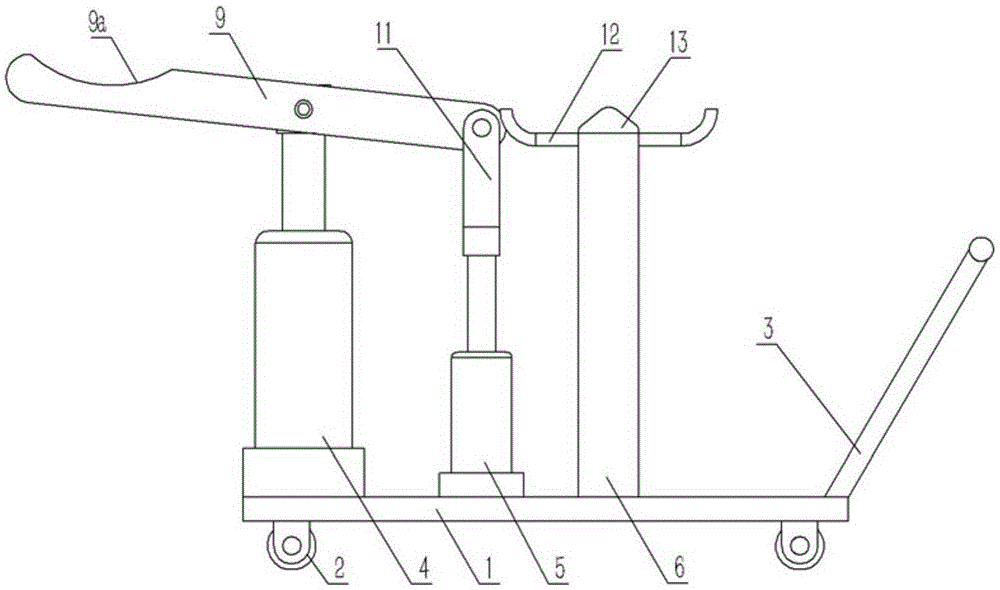

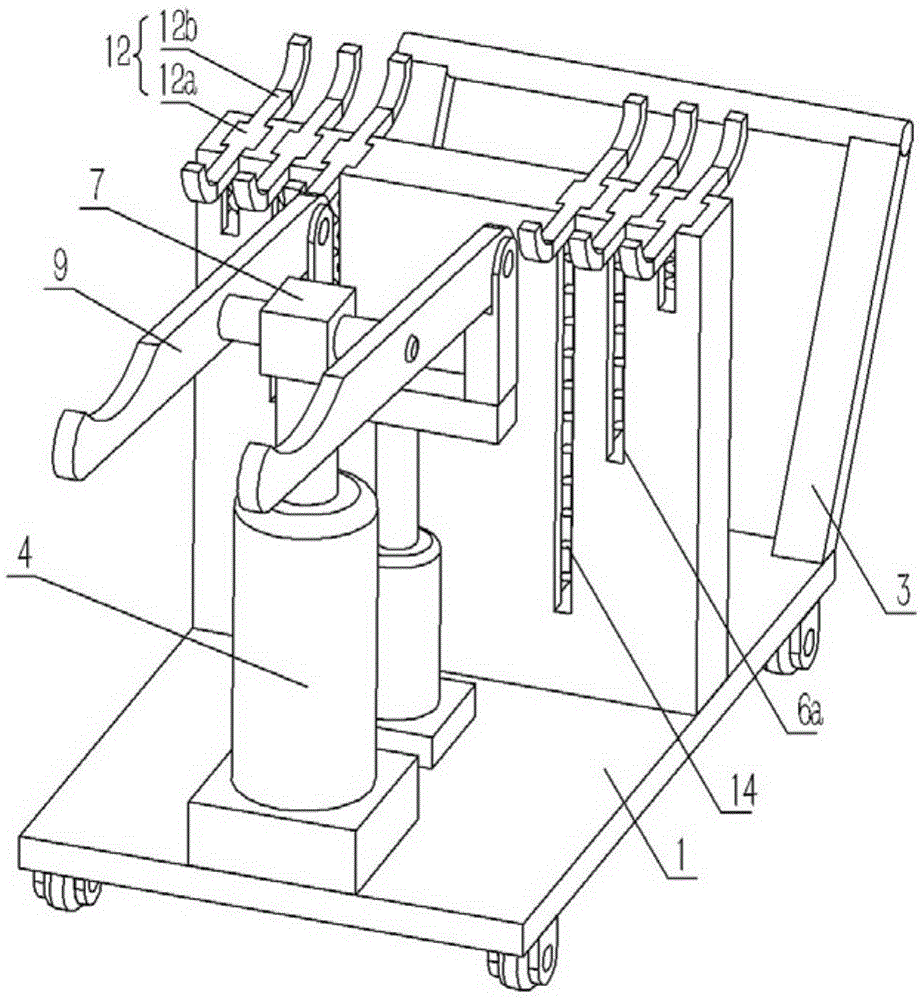

[0015] Example: see figure 1 , 2 As shown in . and 3, a kind of textile cart comprises a vehicle floor 1, wheels 2 and handrails 3, a column 6 is fixed on the vehicle floor 1, and several Chinese-shaped grooves 6a of different lengths are formed on the column 6, and the grooves 6a is inserted with a compression spring 14, and the upper end of the compression spring 14 is pressed against a support rod 12. The support rod 12 includes a Chinese-shaped connection part 12a and a curved rod part 12b formed at the front and rear ends of the connection part 12a. The connection of the support rod 12 The part 12a is inserted into the groove 6a of the column 6, and the upper end surface of the support rod 12 is provided with a triangular top cover 13, and one end of the top cover 13 is hinged on the column 6 through a hinge;

[0016] Lifting oil 4 and auxiliary oil cylinder 5 are respectively fixed on the vehicle floor 1 on the front side of the column 6, and a connecting block 7 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com