Multifunctional trash can suitable for being automatically collected by mechanical arms

A manipulator, multi-functional technology, applied in the direction of trash cans, garbage collection, application, etc., can solve the problems of trash cans that cannot be dumped cleanly, trash cans that cannot be covered, and easy to knock over trash cans, etc., to achieve good sealing, prevent Scattering, less dirt residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

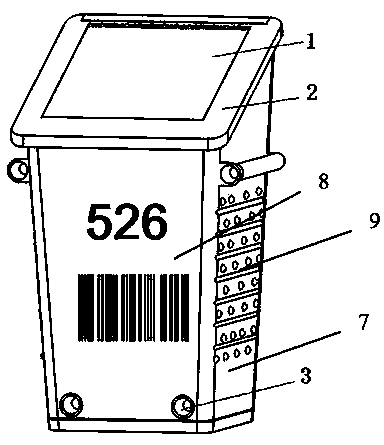

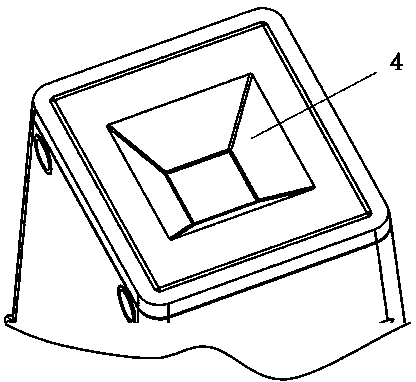

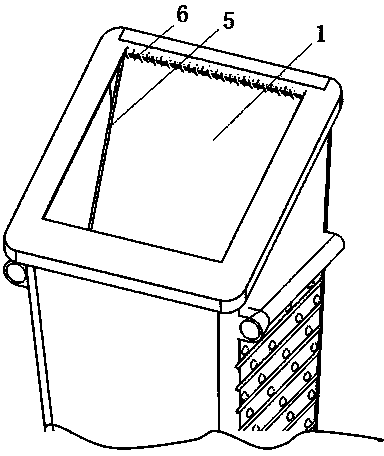

[0034] Such as Figure 1 ~ Figure 4 As shown, a multifunctional garbage can suitable for automatic collection by manipulators of the present invention includes a barrel body 7 and a cover assembly. The cover assembly is arranged on the top of the barrel body 7 and is inclined to the horizontal plane. The outer cover 2 and the inner cover 1 have a double-door combined structure. An opening is provided in the middle of the outer cover 2. An inner cover 1 that can only be opened inward is provided at the opening, and a torsion return spring is provided at the inner cover 1.

[0035] In this embodiment, metal strips are embedded in the edge of the openable side of the outer cover 2 to increase the weight. One side of the outer cover 2 is hinged with the barrel body of the barrel body 7, and a limit is set at the hinge to ensure that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com