Intensive sorting method and shuttle sorting car for small batches of cigarettes

A technology of shuttle sorting vehicles and small batches, which is applied in the field of shuttle picking vehicles, can solve problems such as increased production and storage costs, inconvenient maintenance, and complex systems, and achieve the effects of convenient maintenance, small size, and simplified systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0074] For the dense storage channel of small brand cigarettes with pallets as the carrier, the picking of single cigarettes can also be realized by using this shuttle sorting vehicle. The thickness of the tray is small, and direct pulling will cause impact, which will affect the running stability. The lifting platform device can be installed on the lifting mechanism 4 to solve this problem: when the equipment picks up cigarettes, the platform falls, leaving enough space for picking cigarettes ; When the equipment picks pallets, the platform rises to reduce the pallet drop and run smoothly.

[0075] In order to further illustrate the present embodiment, it is described in conjunction with accompanying drawing:

[0076] 1. Structure description:

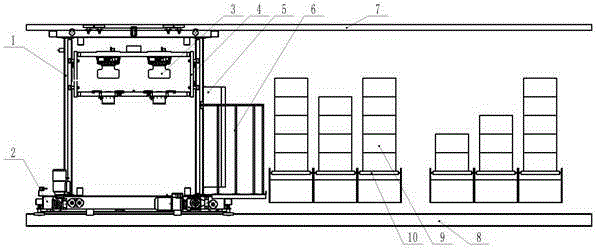

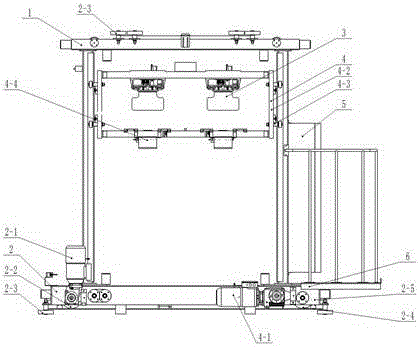

[0077] Such as figure 2 Schematic diagram of the shuttle picking vehicle, Figure 9 The schematic diagram of the system with pallet picking function is shown as follows:

[0078] The lifting platform device 12 on the lifting mech...

Embodiment 3

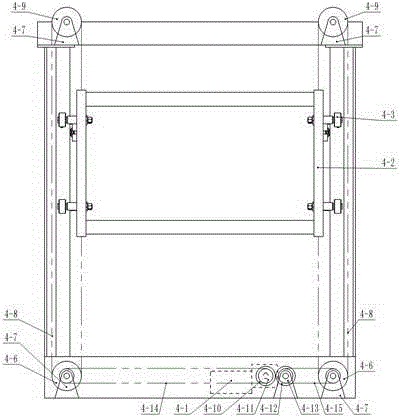

[0087] The lifting platform device 12 on the lifting mechanism 4 described in the second embodiment can be replaced by the turning platform mechanism 14 on the lifting mechanism 4, and its purpose is the same, only the form of the structure is changed.

[0088] Described overturning platform mechanism 14 is made of two sets of overturning motor fixing plates 14-1 fixed on the lifting frame 4-2, overturning motor 14-2, and overturning plate 14-3. 14-1 is fixed on the lifting frame 4-2, and the turnover plate 14-3 is fixed on the output shaft end of the turnover motor 14-2.

[0089] The two sets of turning platform mechanisms 14 work together. Through the rotation of the turning motor 14-2, the two turning plates 14-3 can form a platform for carrying trays. When picking cigarettes, the two turning plates 14-3 are reset. The picking process of trays and pieces of cigarettes has been described in detail in the above embodiments, and will not be described too much here. It is worth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com