A deep-water winch wave compensation hydraulic drive system with load adaptability

A technology of wave compensation and adaptability, applied to clockwork mechanism, hoisting device, etc., can solve problems such as system heating, difficult online quick adjustment, power waste, etc., to reduce system power consumption, ensure rapidity, and realize wireless The effect of level regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

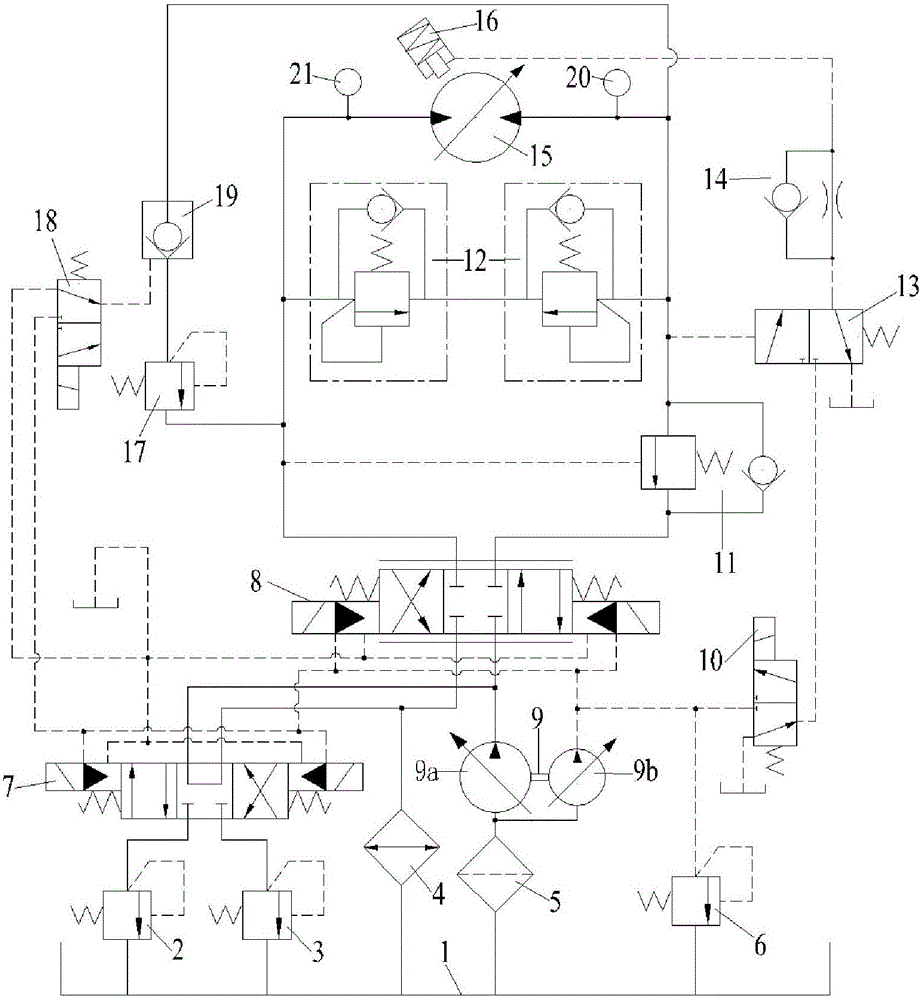

[0027] The present invention designs a deep-water winch wave compensation hydraulic drive system with load adaptability. The system includes three parts: the main lifting circuit, the braking circuit and the constant tension control circuit;

[0028] like figure 1 As shown, the main lifting circuit includes the main pump 9a of the hydraulic pump group, the electro-hydraulic servo valve 8, the three-position four-way electromagnetic reversing valve 7, the first overflow valve 2, the second overflow valve 3, the balance valve 11, Two-way safety overflow valve 12, variable hydraulic motor 15, the outlet of the main pump 9a of the hydraulic pump group are respectively connected to the inlet of the electro-hydraulic servo valve 8 and the inlet of the three-position four-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com