Efficient anaerobic reactor used for fuel ethanol waste water secondary anaerobic treatment

A fuel ethanol wastewater, anaerobic reactor technology, applied in anaerobic digestion treatment, waste fuel and other directions, can solve the problems of inappropriate large-scale treatment system, high viscosity of primary anaerobic effluent, difficult liquid-solid separation, etc. Solid-liquid retention efficiency, improving biochemical reaction efficiency, and improving the effect of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

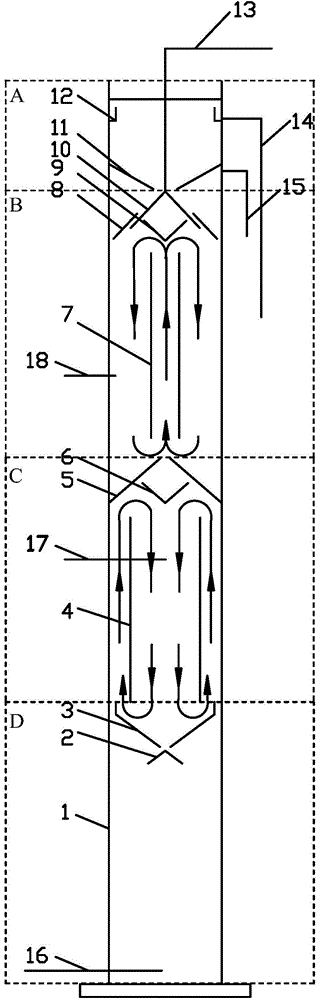

[0024] like figure 1As shown, the present invention proposes a novel high-efficiency anaerobic reactor, including a cylinder 1, which is divided into four sections from bottom to top, which are respectively complete mixing zone, internal circulation zone 1, internal circulation zone 2 and solid-liquid separation area. The waste water enters the complete mixing zone through the bottom inlet pipe 16. There are granular sludge and flocculent sludge in the sludge in the complete mixing zone. In this zone, it is completely mixed and a large amount of biogas is produced under the action of anaerobic bacteria. After the biogas is generated, it is guided by the first mud guide plate 2 and the first air guide plate 3, enters the annular gap between the first air guide plate 3 and the cylinder body 1, rises along the cylinder body and enters the first inner loop in the inner circulation zone 1. The annular space between the circulation sleeve 4 and the cylinder body 1, with the gas li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com