Yellow fluorescent powder and preparation method thereof

A yellow phosphor powder and temperature control technology, which is applied in the field of yellow phosphor powder and its preparation, can solve problems such as glare, poor color rendering of LEDs, and uneven luminescence, and achieve the goals of reducing reaction temperature and time, uniform distribution, and high luminous efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

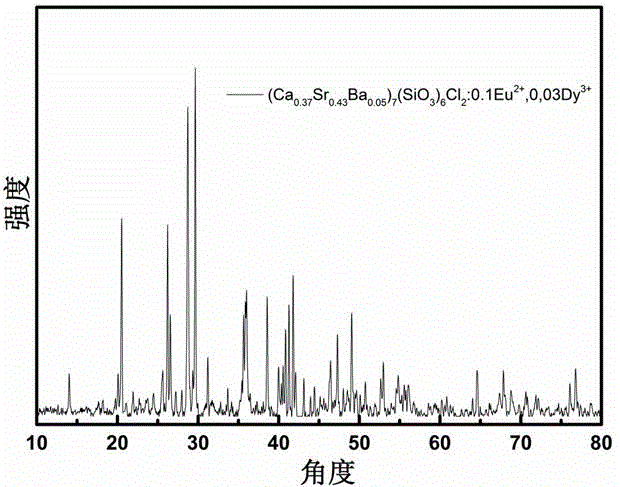

[0018] A kind of yellow fluorescent powder, its general chemical formula is (Ca 0.37 ,Sr 0.53-x-y , Ba x ) 7 (SiO 3 ) 6 Cl 2 :0.10Eu 2+ , y Dy 3+ , where x=0.05, y=0.03, that is (Ca 0.37 ,Sr 0.45 , Ba 0.05 ) 7 (SiO 3 ) 6 Cl 2 :0.10 Eu 2+ , 0.03 Dy 3+ .

[0019] The above-mentioned preparation method of a yellow fluorescent powder is characterized in that the steps are as follows:

[0020] First calculated by molar ratio, CaCO 3 : SrCl 2 .6H 2 O: BaCl 2 : SiO 2 : Eu 2 o 3 : Dy 2 o 3 is 2.59: k (3.71-7 x -7 y ): 7 x :7.2:0.7:7 y proportion of which k =6.85, x=0.05, y=0.03, namely CaCO 3 : SrCl 2 .6H 2 O: BaCl 2 : SiO 2 : Eu 2 o 3 : Dy 2 o 3 For the ratio of 2.59:23.625:0.35:7.2:0.7:0.21, the CaCO 3 、Eu 2 o 3 、Dy 2 o 3 , BaCl 2 , SiO 2 and SrCl 2 .6H 2 O was thoroughly mixed and ground in an agate mortar, then put into a tangerine pot, put into a muffle furnace for reduction by buried charcoal method, and sintered at a constant ...

Embodiment 2

[0024] A kind of yellow fluorescent powder, its general chemical formula is (Ca 0.37 ,Sr 0.53-x-y , Ba x ) 7 (SiO 3 ) 6 Cl 2 :0.10Eu 2+ , y Dy 3+ , where x=0.10, y=0.03, that is (Ca 0.37 ,Sr 0.40 , Ba 0.10 ) 7 (SiO 3 ) 6Cl 2 :0.10 Eu 2+ ,0.03Dy 3+ .

[0025] The above-mentioned preparation method of a yellow fluorescent powder is characterized in that the steps are as follows:

[0026] First calculated by molar ratio, CaCO 3 : SrCl 2 .6H 2 O: BaCl 2 : SiO 2 : Eu 2 o 3 : Dy 2 o 3 2.59: k (3.71-7 x -7 y ): 7 x :7.2:0.7:7 y proportion of which k =7.5, x=0.10, y=0.03, namely CaCO 3 : SrCl 2 .6H 2 O: BaCl 2 : SiO 2 : Eu 2 o 3 : Dy 2 o 3 For the ratio of 2.59:21:0.7:7.2:0.7:0.21, the CaCO 3 、Eu 2 o 3 、Dy 2 o 3 , BaCl 2 , SiO 2 and SrCl 2 .6H 2 O was thoroughly mixed and ground in an agate mortar, then put into a tangerine pot, put into a muffle furnace for reduction by buried charcoal method, and sintered at a constant temperature...

Embodiment 3

[0029] A kind of yellow fluorescent powder, its general chemical formula is (Ca 0.37 ,Sr 0.53-x-y , Ba x ) 7 (SiO 3 ) 6 Cl 2 :0.10Eu 2+ , y Dy 3+ , where x=0.10, y=0.01, that is (Ca 0.37 ,Sr 0.42 , Ba 0.10 ) 7 (SiO 3 ) 6 Cl 2 :0.10 Eu 2+ , 0.01Dy 3+ .

[0030] The above-mentioned preparation method of a yellow fluorescent powder is characterized in that the steps are as follows:

[0031] First calculated by molar ratio, CaCO 3 : SrCl 2 .6H 2 O: BaCl 2 : SiO 2 : Eu 2 o 3 : Dy 2 o 3 is 2.59: k (3.71-7 x -7 y ): 7 x :7.2:0.7:7 y proportion of which k =4, x=0.10, y=0.01, namely CaCO 3 : SrCl 2 .6H 2 O: BaCl 2 : SiO 2 : Eu 2 o 3 : Dy 2 o 3 For the ratio of 2.59:11.76:0.7:7.2:0.7:0.07, the CaCO 3 、Eu 2 o 3 、Dy 2 o 3 , BaCl 2 , SiO 2 and SrCl 2 .6H 2 O was thoroughly mixed and ground in an agate mortar, then put into a tangerine pot, put into a muffle furnace for reduction by buried charcoal method, and sintered at a constant tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

| internal quantum efficiency | aaaaa | aaaaa |

| internal quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap