Rubber jacketed flexible cable aluminum alloy conductor material and manufacturing method thereof

A technology for aluminum alloy conductors and manufacturing methods, which is applied in the direction of metal/alloy conductors, etc., can solve the problems of high conductivity, low manufacturing cost, and no guidance plan, etc., and achieve high conductivity, low manufacturing cost, and good flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

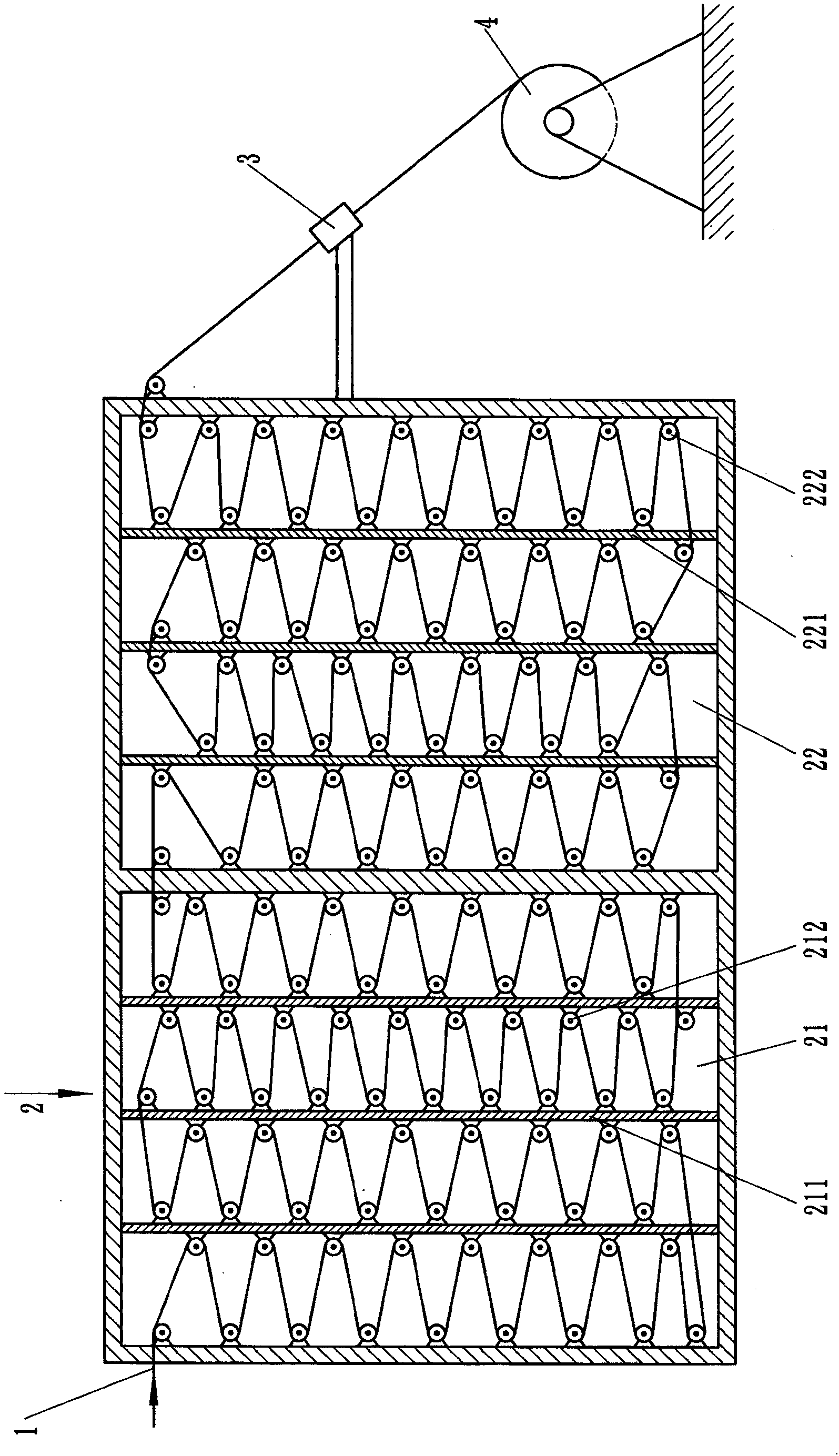

Image

Examples

Embodiment 1

[0016] Embodiment 1: The mass percentage (weight percentage) of each component in the aluminum alloy conductor material of the rubber-sheathed flexible cable is as follows (taking the production of about 10,000 kg of aluminum alloy electrical poles as an example):

[0017] Pure iron powder: 3% (choose 300kg, purity 99.90%), niobium-tin intermediate ingot: 0.5% (choose 50kg), aluminum-boron alloy: 0.25% (choose 25kg), the balance is aluminum and ≤0.5% total amount of impurities. The above-mentioned aluminum is electrolytic aluminum liquid (approximately 9625 kg). The particle size of the above-mentioned pure iron powder is 80 mesh, and its carbon content is ≤0.03% (the carbon content is 0.02%).

[0018] The mass percentage of niobium in the niobium-tin intermediate ingot is 30%, and the mass percentage of tin is 70%. The manufacturing method of the niobium-tin intermediate ingot is to use a lathe to process the niobium metal block into niobium shavings (crumbs), put it into a...

Embodiment 2

[0023] Example 2: The mass percentage (weight percentage) of each component in the aluminum alloy conductor material of the rubber-sheathed flexible cable is as follows: pure iron powder: 3.5% (or 3.3%), niobium-tin intermediate ingot: 0.7% (or 0.6%), Aluminum-boron alloy: 0.26% (or 0.28%), the balance is aluminum and ≤0.5% of the total amount of impurities. The particle size of the above-mentioned pure iron powder is 100 mesh (or 90 mesh), and its carbon content is ≤0.03% (the carbon content is 0.025% or 0.03%);

[0024] The mass percentage of niobium in the above-mentioned niobium-tin intermediate ingot is 30%, the balance is tin, and the sum of the mass percentages of niobium and tin is 100%. The manufacturing method of the described niobium-tin intermediate ingot is to use a lathe Process it into niobium chips, put it into a Gan boiler and heat it to 1800~2200°C (choose 1800°C or 2000°C or 2200°C) to melt it, then put tin metal block at this temperature to melt it, and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap