Sand lifting and energy storing power station

A technology of energy storage power station and sand bank, which is applied in the direction of machines/engines, mechanical equipment, engines, etc., can solve the problems of low carrying capacity, difficult loading and unloading, and high energy consumption, so as to achieve strong energy storage capacity and power generation capacity, and save time The effect of low labor cost and strong cargo carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

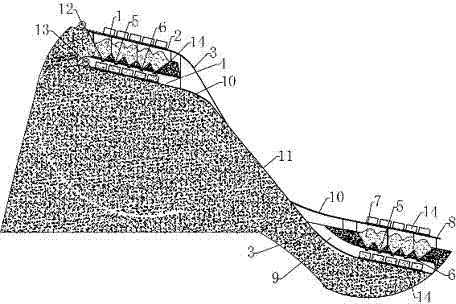

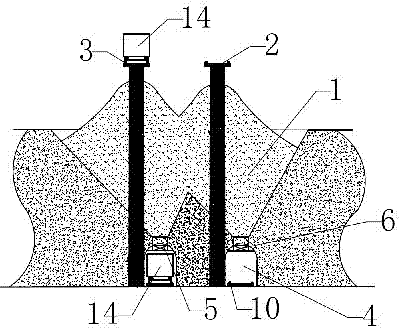

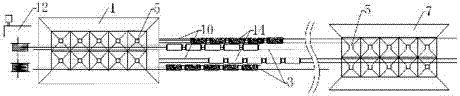

[0029] like figure 1 , figure 2 , image 3 As shown, both the high-level sand bank 1 and the low-level sand bank 7 are inclined, and two rows of sand buckets in the shape of an inverted pyramid are arranged at the bottom of the bank along the narrow and long direction, and a sand leakage port 5 is provided at the tip of the sand bucket. The number of every row of sand buckets 5 is 5, the first tunnel 4 and the second tunnel 9 are double-hole tunnel groups, a row of sand leaks 5 are provided directly above each tunnel, and the ends of the two tunnels are connected to each other. China Unicom.

[0030] Both the first track 3 and the second track 10 are double-track, and the first track 3 and the second track 10 are independent of each other.

[0031] The power and transmission system in the ground cable car sand lifting device 12 and the ground cable car power generation device 13 are independent of each other, and the cable car 14 running mode in the ground cable car sand l...

Embodiment 2

[0034] like figure 1 , figure 2 , image 3 As shown, the high-level sand bank 1 and the low-level sand bank 7 are both horizontal, and 4 rows of inverted pyramid-shaped sand buckets are arranged along the narrow and long direction at the bottom of the tank, and a sand leakage port 5 is provided at the tip of the sand bucket. The number of sand buckets 5 in each row is 20, the first tunnel 4 and the second tunnel 9 are double-hole tunnel groups, and 2 rows of sand leakage outlets 5 are arranged side by side directly above each tunnel, and the ends of the two tunnels are interconnected.

[0035] Both the first track 3 and the second track 10 are double-track, and the first track 3 and the second track 10 are independent of each other.

[0036] The power and transmission system in the ground cable car sand lifting device 12 and the ground cable car power generation device 13 are independent of each other, and the cable car 14 running mode in the ground cable car sand lifting ...

Embodiment 3

[0039] like figure 1 , figure 2 , image 3 As shown, both the high-level sand bank 1 and the low-level sand bank 7 are inclined, and two rows of sand buckets in the shape of an inverted pyramid are arranged at the bottom of the bank along the narrow and long direction, and a sand leakage port 5 is provided at the tip of the sand bucket. The number of sand buckets 5 in each row is 10, the first tunnel 4 and the second tunnel 9 are single-hole tunnels, and a row of sand leaks 5 is provided directly above each tunnel, and the ends of the two tunnels are interconnected of.

[0040] Both the first track 3 and the second track 10 are monorail tracks with staggered lanes in the middle, and the first track 3 and the second track 10 are independent of each other.

[0041] The power and transmission system in the ground cable car sand lifting device 12 and the ground cable car power generation device 13 are independent of each other, and the cable car 14 running mode in the ground c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com